High-strength high-toughness and high-plasticity low-carbon medium-manganese medium-thickness plate and manufacturing method thereof

A high-strength, toughness technology, applied in the field of steel materials, can solve the problems of plasticity and toughness decline, high yield ratio, limited capacity, etc., and achieve the effect of uniform thickness structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

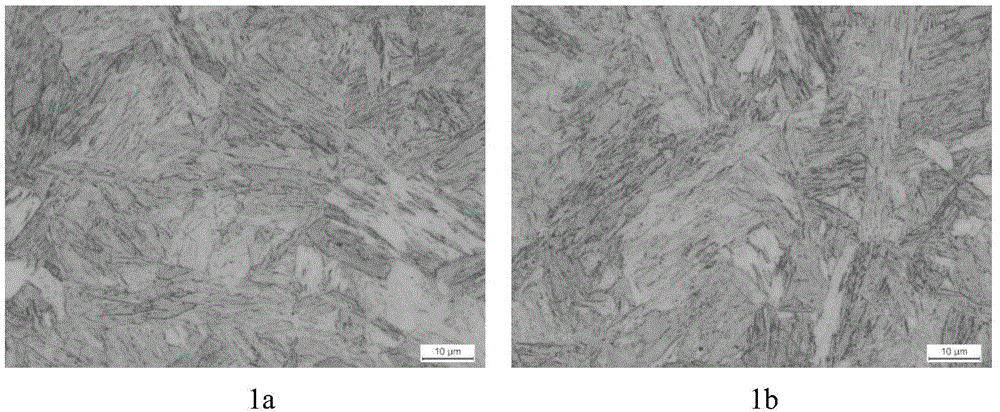

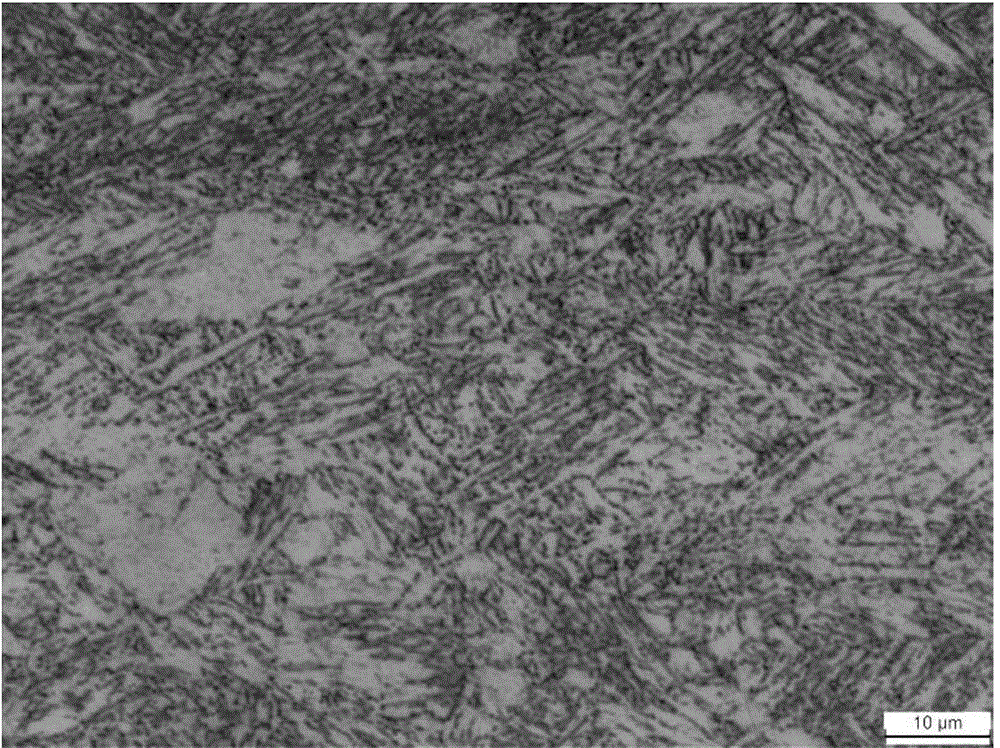

[0033] The chemical composition of the high-strength, tough and plastic low-carbon medium-manganese medium-thick plate with a thickness of 40mm is: C: 0.032%, Si: 0.36%, Mn: 5.8%, P: 0.002%, S: 0.003 %, Ni: 1.48%, the balance is Fe and unavoidable impurities; its microstructure is tempered martensite and fine ferrite + metastable austenite structure, and the structure of the surface of the steel plate is the same as that of the core ; Its yield strength is 700MPa, tensile strength is 820MPa, elongation after fracture is 28%, and the impact absorption energy of -60 ℃ Charpy V-notch standard sample is 200J, and the impact absorption energy of -80 ℃ Charpy V-notch standard sample The impact absorption energy is 160J, and the yield ratio is 0.85.

[0034] The preparation method of above-mentioned plate is carried out according to the following steps:

[0035] Heat a 70mm thick billet to 1200°C and keep it warm for 3 hours. The chemical composition is as follows: C: 0.032%, Si: 0....

Embodiment 2

[0041] The chemical composition of high-strength, toughness and plastic low-carbon medium-manganese plate with a thickness of 20mm is: C: 0.039%, Si: 0.29%, Mn: 3.9%, P: 0.004%, S: 0.002 %, Ni: 0.98%, the balance is Fe and unavoidable impurities; its microstructure is tempered martensite and fine ferrite + metastable austenite structure, and the structure of the surface of the steel plate is the same as that of the core ; Its yield strength is 570MPa, tensile strength is 665MPa, elongation after fracture is 29%, the impact absorption energy of -60 ℃ Charpy V-notch standard sample is 245J, -80 ℃ Charpy V-notch standard sample The impact absorption energy is 225J, and the yield ratio is 0.86.

[0042] The manufacturing method of above-mentioned plate is carried out according to the following steps:

[0043] Heat a steel billet with a thickness of 70mm to 1200°C and hold it for 2.5 hours. The chemical composition of the billet is: C: 0.039%, Si: 0.29%, Mn: 3.9%, P: 0.004%, S: 0.00...

Embodiment 3

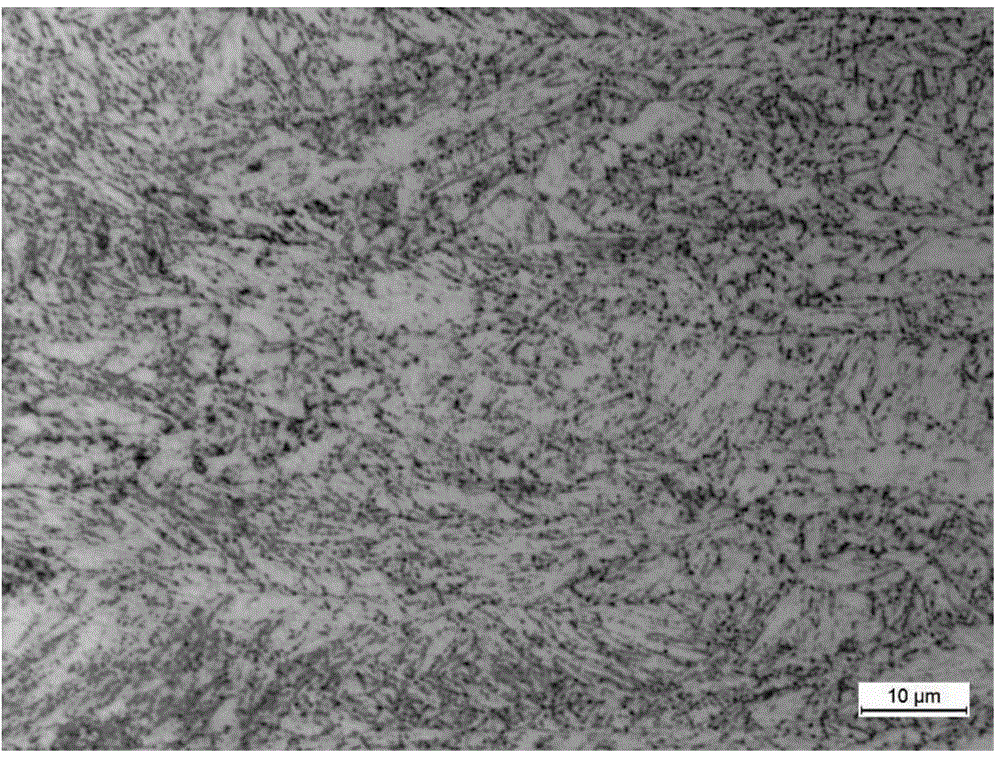

[0049] High-strength, tough and plastic low-carbon medium-manganese medium-thick plate with a thickness of 10mm, its chemical composition is: C: 0.05%, Si: 0.2%, Mn: 3.0%, P: 0.005%, S: 0.001 %, Ni: 0.5%, the balance is Fe and unavoidable impurities; its microstructure is tempered martensite and fine ferrite + metastable austenite structure, and the structure of the surface of the steel plate is the same as that of the core ; Its yield strength is 520MPa, tensile strength is 620MPa, elongation after fracture is 32%, the impact absorption energy of -60 ℃ Charpy V-notch standard sample is 210J, -80 ℃ Charpy V-notch standard sample The impact absorption energy is 195J, and the yield ratio is 0.84.

[0050] The preparation method of above-mentioned plate is carried out according to the following steps:

[0051] Heat a 70mm thick billet to 1200°C and hold it for 2 hours. The chemical composition of the billet is as follows: C: 0.05%, Si: 0.2%, Mn: 3.0%, P: 0.005%, S: 0.001%, Ni: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com