Al-Er-Cu high-strength high-electric conductivity aluminium alloy and thermomechanical treatment technology thereof

An al-er-cu, high-conductivity technology, applied in the field of metal alloys, can solve the problems of the greater influence of the conductivity of aluminum alloys and the low conductivity of alloys, and achieve the effect of improving strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1: An alloy ingot was prepared by smelting in a graphite crucible and casting in an iron mold, and the raw materials used were high-purity aluminum and an intermediate alloy of Al-6% Er and Al-50% Cu. At a smelting temperature of 770±10°C, first melt the aluminum ingot, then add Al-6% Er, Al-50% Cu master alloy, after the master alloy is melted, fully stir, keep it warm for 10 minutes, and make the melt Iron mold casting is carried out after the components of each element are evenly distributed. Al-Cu alloys and three Al-Er-Cu alloys with different compositions were prepared, as shown in Table 1 below.

[0021] Table 1 Experimental alloy composition

[0022] sample

example 2

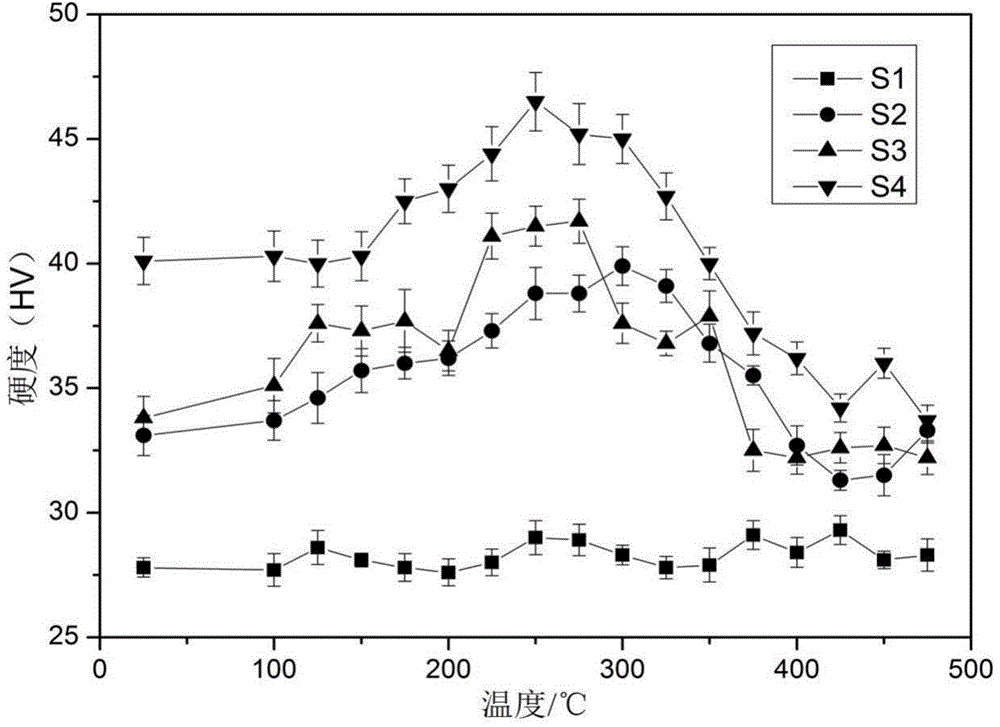

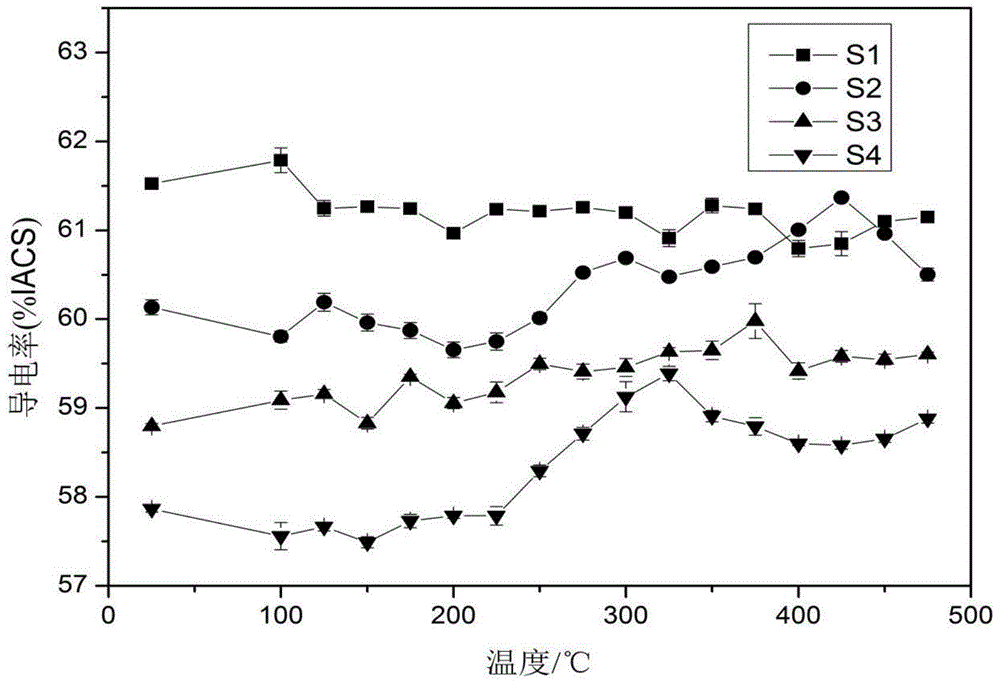

[0023] Example 2: The S1 alloy in Example 1 was solid-dissolved at 500±10°C for 24 hours, water quenched to room temperature, and subjected to isochronous annealing at 100-475°C, and samples were taken every 25°C. S2, S3, and S4 alloys were solid-dissolved at 640±10°C for 24 hours, water-quenched to room temperature, and annealed at 100-475°C, and the same was taken every 25°C. figure 1 The Vickers hardness of the alloy at different temperatures is given. It can be seen from the figure that the hardness value of the S1 alloy is about 28HV, basically unchanged. The S2 alloy reaches the hardness peak of 39.9HV at 300°C, and the S3 alloy reaches the hardness peak value of 41.7 at 275°C. HV, S4 alloy reaches the peak hardness of 46.5HV at 250℃. It shows that the addition of Er element to Al-Cu has a time-aging strengthening effect, and with the increase of Cu element content, the hardness peak value also increases continuously, and at the same time the temperature at the peak poi...

example 3

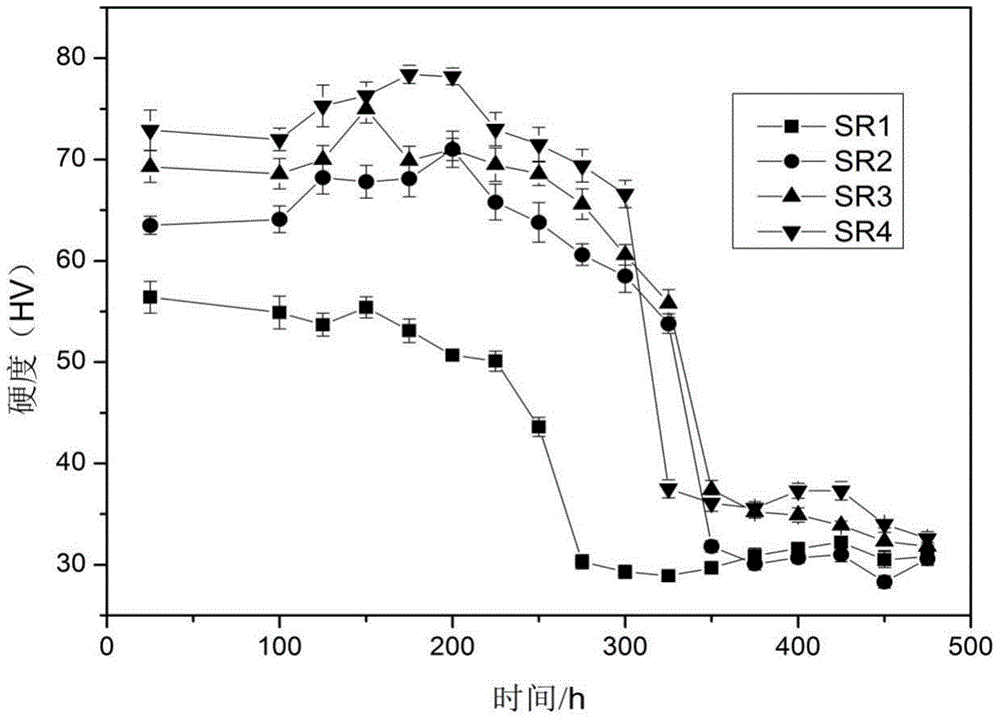

[0024] Example 3: Perform solution treatment (500±10°C / 24h) on the S1 alloy in Example 1, perform peak aging treatment after solution treatment (640±10°C / 24h) on S2, S3, and S4 alloys, and peak aging of S2 alloy The heat treatment process is 100-300°C every 25°C isochronous annealing for 3 hours, the S3 alloy peak aging heat treatment process is 100-275°C every 25°C isochronous annealing for 3 hours, the S4 alloy peak aging heat treatment process is 100-250°C every Anneal at intervals of 25°C for 3 hours. Then the solid solution state of the S1 alloy, the solid solution state and the peak aging state of the S2, S3, and S4 alloys are cold-rolled respectively, and the cold rolling deformation is about 90%. Then measure its hardness value and conductivity. The obtained data are shown in Table 2. It can be seen from the table that with the increase of Cu content, the hardness value after cold rolling deformation gradually increases, while the electrical conductivity gradually de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com