Silicone adhesive composition, method for making the same and adhesive film

A technology of silicone adhesive and composition, which is applied in the direction of film/sheet adhesive, adhesive, transportation and packaging, etc. It can solve the problem that it is difficult to sufficiently reduce the amount of low-molecular siloxane and the adhesive tape has poor adhesion , Poor transparency of the composition, etc., to achieve the effects of inhibiting the adhesion of foreign matter such as silica on the surface of the cured product, reducing migration, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

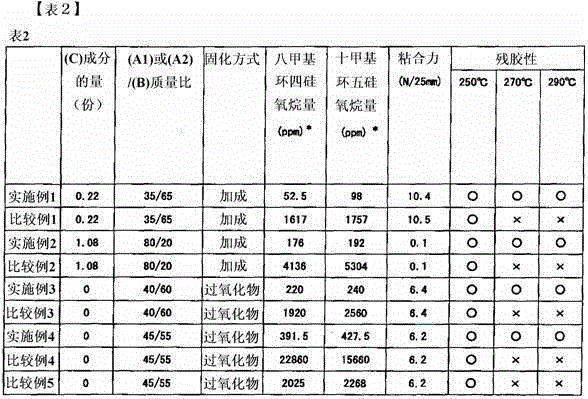

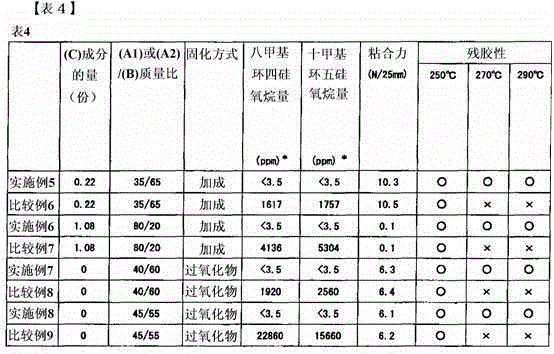

[0106] Hereinafter, the present invention will be described in detail using Examples and Comparative Examples, but the present invention is not limited to the following Examples. In addition, "part" and "%" represent "mass part" and "mass %", respectively, Me represents a methyl group, and Vi represents a vinyl group. In the following description, the viscosity is a value at 25°C measured by a rotational viscometer.

[0107] The measurement conditions of gas chromatography (GC) are as follows.

[0108] Gas chromatograph: Capillary gas chromatograph (Hitachi G-3500)

[0109] Column: DURABOND.DB-5MS from J&W Company (0.53mm×30m×1.0μm)

[0110] Detector: FID, temperature 300℃

[0111] Heating program: 50°C→10°C / min→280°C (17 minutes)

[0112] Injection port temperature: 270℃

[0113] Carrier gas: Helium (5ml / min)

[0114] Injection volume: 2 μl.

[0115] The following test methods were used.

[0116] initial adhesion

[0117] The silicone adhesive composition was applie...

preparation example 1

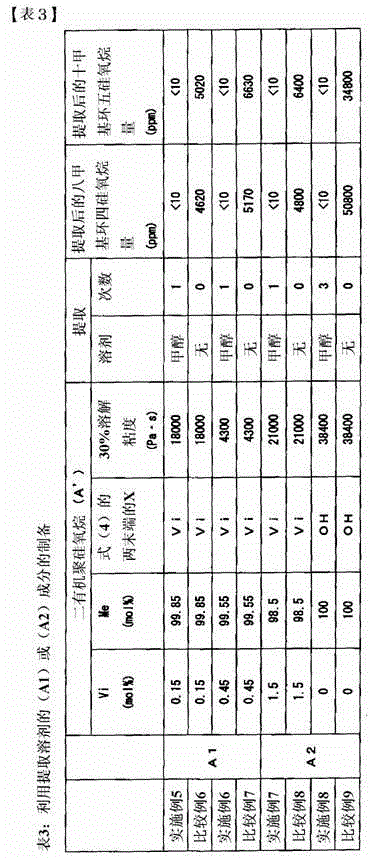

[0122] Preparation Example 1: Preparation of (A1) or (A2) Component Using Stripping

[0123] A raw rubber-like diorganopolysiloxane (A') having a viscosity of 18,000 mPa·s and a vinyl content of 0.15 mol % when dissolved in toluene at a concentration of 30% represented by the following formula (4) ) 100 parts by weight were dissolved in 100 parts by weight of toluene to obtain a toluene solution. The operation of stripping the solution at 160° C. and 20 mmHg while stirring was performed once to obtain the component (A1). In addition, the said vinyl content shows the ratio (mol%) of the amount of vinyl groups with respect to the total amount of the organic group (methyl group and vinyl group) in the said diorganopolysiloxane (A').

[0124] XMe 2 SiO (ViMeSiO) m (Me 2 SiO) n SiMe 2 X (4).

[0125] Here, X existing at both ends is a Vi group or an OH group in common, m and n are as defined above, and m+n is the viscosity of the diorganopolysiloxane when dissolved in tolu...

Embodiment 1

[0128] Mix the following ingredients:

[0129] 35 parts of (A1) component obtained in Preparation Example 1,

[0130] Contains Me 3 SiO 0.5 Cell and SiO 2 Units of organopolysiloxane (component (B)) (Me 3 SiO 0.5 Unit / SiO 2 Unit = 0.85) 60% toluene solution 108.3 parts,

[0131] 23.7 parts of toluene,

[0132] SiH group-containing organohydrogenpolysiloxane of the following formula (component (C)) 0.22 parts,

[0133] Me 3 SiO (HMeSiO) 40 SiMe 3 ,as well as

[0134] Ethynylcyclohexanol (component (D)) 0.20 part.

[0135] To the above mixture (about 60% of the siloxane component) (100 parts), toluene (50 parts) and a platinum-vinyl group-containing siloxane complex (component (E)) containing 0.5 mass % of the platinum component were added. A toluene solution (0.5 part) was further mixed to prepare a silicone adhesive composition having a silicone content of about 40%. With respect to the obtained silicone adhesive composition, each test was performed according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com