Chromium-free chemical conversion treatment method for magnesium alloy surface

A chemical conversion treatment and surface pretreatment technology, applied in the direction of metal material coating process, etc., can solve the problem that the corrosion resistance and self-healing ability of the conversion film have not fully met the requirements for use, the corrosion resistance is not as good as chromate treatment, phosphorus There are many problems in the composition of the chemical liquid, so as to achieve the effect of convenient industrial application, low cost, and expansion of production and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

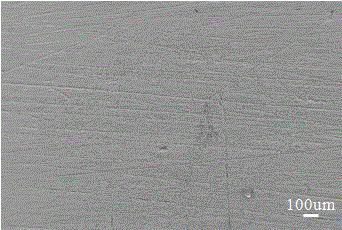

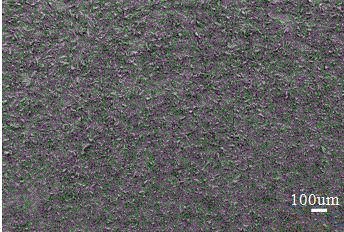

[0023] The magnesium flakes are processed into a size of 60mm×30mm×1mm and then polished, put into a potassium carbonate solution with a mass fraction of 5% to wash and remove oil for 7 minutes, then take it out and wash it with distilled water, and put it into a solution with a mass fraction of 3% hydrogen fluoride pickling in acid for 30s, then take it out and wash it with distilled water, then put it into the -1 Sodium dihydrogen phosphate, 50 g·L -1 Calcium hypophosphite, 8 g L -1 Hexamethylenetetramine, in the 100ml phosphating solution, the phosphating time is 20min, the temperature is 30°C, adjust the pH to 4.6, take it out after the film is formed, wash it with distilled water, dry it with hot air and put it in a sealed bag Sealed. See the result figure 1 and figure 2 ,Compared figure 1 and figure 2 It can be seen that after phosphating treatment, a uniform and dense phosphating film is formed on the surface of the magnesium alloy.

Embodiment 2

[0025] The magnesium flakes are processed into a size of 60mm×30mm×1mm and then polished, put in an 8% sodium hydroxide solution for alkali washing and degreasing for 8 minutes, then take it out and wash it with distilled water, and put it in 4% nitric acid pickling in medium for 20s, then take it out and wash it with distilled water, and then put it into 40 g·L -1 Sodium dihydrogen phosphate, 40 g·L -1 Calcium hypophosphite, 4 g L -1 In the 100ml phosphating solution composed of hexamethylenetetramine, the phosphating time is 18min, the temperature is 20°C, adjust the pH to 3.0 with water, take it out after the film is formed, wash it with distilled water, dry it with hot air and put it in a sealed bag Sealed. Its SEM image can refer to figure 1 and figure 2 .

Embodiment 3

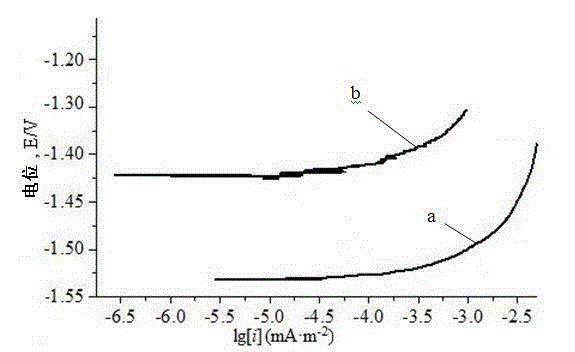

[0027] The magnesium flakes are processed into a size of 60mm×30mm×1mm and then polished, put in a potassium hydroxide solution with a mass fraction of 6% to wash and remove oil for 8 minutes, then take it out and wash it with distilled water, and put in a phosphoric acid with a mass fraction of 7% pickling in medium for 15s, then take it out and wash it with distilled water, and then put it into 20 g·L -1 Sodium dihydrogen phosphate, 60 g·L -1 Calcium hypophosphite, 6g·L -1 In the 100ml phosphating solution composed of hexamethylenetetramine, the phosphating time is 25min, the temperature is 15°C, and the pH is adjusted to 2.9. After the film is formed, take it out, wash it with distilled water, dry it with hot air, put it in a sealed bag and seal it deal with. Its SEM image can refer to figure 1 and figure 2 . image 3 The polarization curves of the magnesium sheet (a) curve and the conversion coating (b) curve prepared in Example 3 in 3.5% NaCl solution. Depend on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com