Fast-curing instant glue and preparation method thereof

A technology of instant glue and nitrile rubber, applied in the field of instant glue, can solve problems such as low odor, and achieve the effects of small odor, improved flexibility, and poor thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A fast-curing instant glue, its components are:

[0040]

[0041] 100% quality;

[0042] Add the weighed methyl a-cyanoacrylate, butyl a-cyanoacrylate, and a-cyanoacrylic acid into the reaction kettle, and stir the temperature to 85°C; add the organic solvent and the well-proportioned organic solvent while stirring. Catalyst; then slowly and uniformly add nitrile butadiene rubber while stirring. The stirring time is 100 minutes to make the mixture evenly stirred. Before distillation, add an appropriate amount of polymerization inhibitor; then heat up and steam out the organic solvent to make the residual amount a small amount It should be less than 0.5 (wt)% of the total amount; under the second Roots, the modified a-cyanoacrylate products will be steamed out; in the steamed a-cyanoacrylate products, under nitrogen protection Next, add an appropriate amount of stabilizer and accelerating liquid, and stir evenly.

Embodiment 2

[0044] A fast-curing instant glue, its components are:

[0045]

[0046] 100% quality;

[0047] Add the weighed a-octyl cyanoacrylate and a-cyanoacrylic acid into the reaction kettle, and stir the temperature to 80°C; add the organic solvent and catalyst with a good ratio while stirring; then slowly and uniformly stir while mixing Add nitrile rubber and stir for 120 minutes to make the mixture evenly stirred. Before distilling, add an appropriate amount of polymerization inhibitor; then increase the temperature and steam out the organic solvent so that the residual amount should be 0.5 (wt )% or less; under the secondary roots, steam the modified a-cyanoacrylate products; in the steamed a-cyanoacrylate products, under the protection of nitrogen, add an appropriate amount of stabilizer and Promote liquid, stir evenly.

Embodiment 3

[0049] A fast-curing instant glue, its components are:

[0050]

[0051] 100% quality;

[0052] Add the weighed methoxyethyl a-cyanoacrylate, methoxybutyl a-cyanoacrylate, and a-cyanoacrylic acid into the reaction kettle, stir and heat up to 90℃; add the mixture while stirring The organic solvent and the catalyst have a good ratio; then slowly and uniformly add the nitrile rubber while stirring. The stirring time is 60 minutes to make the mixture evenly stirred. Before the distillation, add an appropriate amount of polymerization inhibitor; then heat up and distill the organic solvent. The residual amount should be less than 0.5 (wt)% of the total amount; under the second Roots, the modified a-cyanoacrylate products will be steamed out; the a-cyanoacrylate products will be steamed out In the product, under the protection of nitrogen, add an appropriate amount of stabilizer and accelerator, and stir evenly.

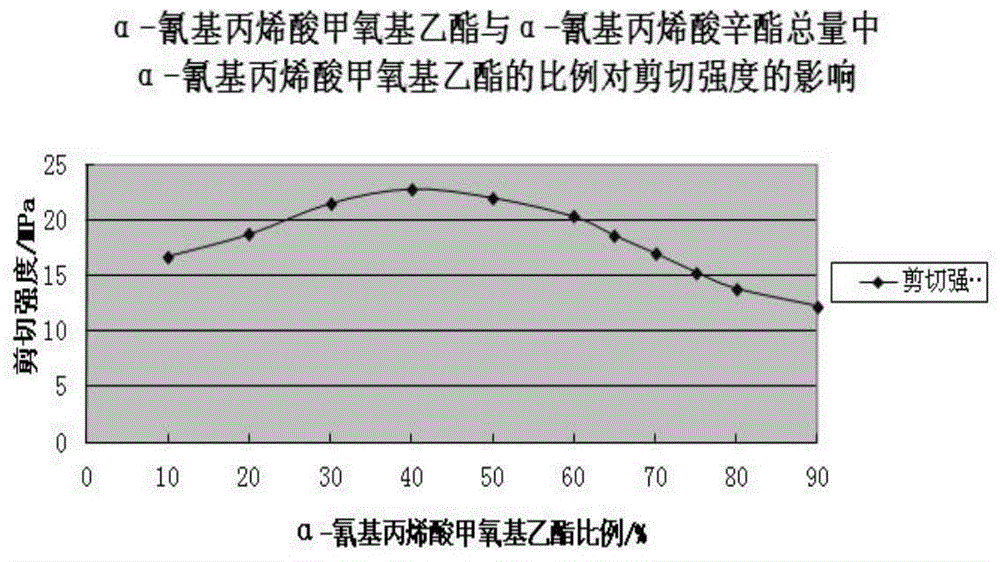

[0053] The following further explains the development process of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com