A kind of preparation method of dense silicon carbide ceramics without boron or rare earth elements

A technology of silicon carbide ceramics and rare earth elements, which is applied in the field of structural ceramics, can solve the problems of difficult to achieve densification of silicon carbide ceramics, and achieve the effects of uniform and meticulous microstructure, good mechanical properties and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for dense silicon carbide ceramics without boron or rare earth elements, carried out as follows:

[0051] Step 1: 12wt% aluminum sol (containing 20wt% AlOOH, calculated as 2wt% AlN by Al), 10.5wt% phenolic resin (calculated as 3wt% C by residual carbon after thermal cracking and carbothermal reduction reaction), 77.5wt% Silicon carbide powder (the average particle size of the powder is 0.4 microns, and the content after thermal cracking and carbothermal reduction reaction is 95wt%) is uniformly mixed with absolute ethanol, ball milled for 4 hours, dried at 60°C, ground and sieved;

[0052] Step 2: After the mixed powder is dry-pressed at 20 MPa, it is placed in an open mold at the top, and it is heated and cracked in a sintering furnace. The sintering furnace is heated to 900 °C at a heating rate of 2 °C / min, and the holding time is 1h, the atmosphere in the heating cracking process is vacuum;

[0053] Step 3: Carry out the carbothermal reduction reaction in t...

Embodiment 2

[0056] Step 1: 12wt% aluminum sol (containing 20wt% AlOOH, calculated as 2wt% AlN by Al), 3.8wt% carbon black (calculated as 3wt% C by residual carbon after carbothermal reduction reaction), 94.2wt% silicon carbide powder powder (the average particle size of the powder is 0.4 microns, and the content after thermal cracking and carbothermal reduction reaction is 95wt%) and absolute ethanol are uniformly mixed, ball milled for 4 hours, dried at 60°C, ground and sieved;

[0057] Step 2: Dry-press the mixed powder at 20 MPa, press isostatically at 200 MPa for 2 minutes, and obtain a ceramic green body;

[0058] Step 3: Place the ceramic green body in the mold with the upper part open, carry out thermal cracking in the sintering furnace, heat the sintering furnace to 900°C at a heating rate of 2°C / min, and keep it for 1h. During the thermal cracking process The atmosphere is a vacuum;

[0059] Step 4: Carrying out the carbothermal reduction reaction in the sintering furnace, heati...

Embodiment 3

[0062] The difference between this embodiment and specific embodiment 1 is that the AlOOH sol in step 1 is replaced by alumina powder, and the raw material composition is 2.2wt% Al 2 o 3 powder, 11.7wt% phenolic resin and 86.1wt% SiC powder. Other steps and parameter are identical with specific embodiment 1;

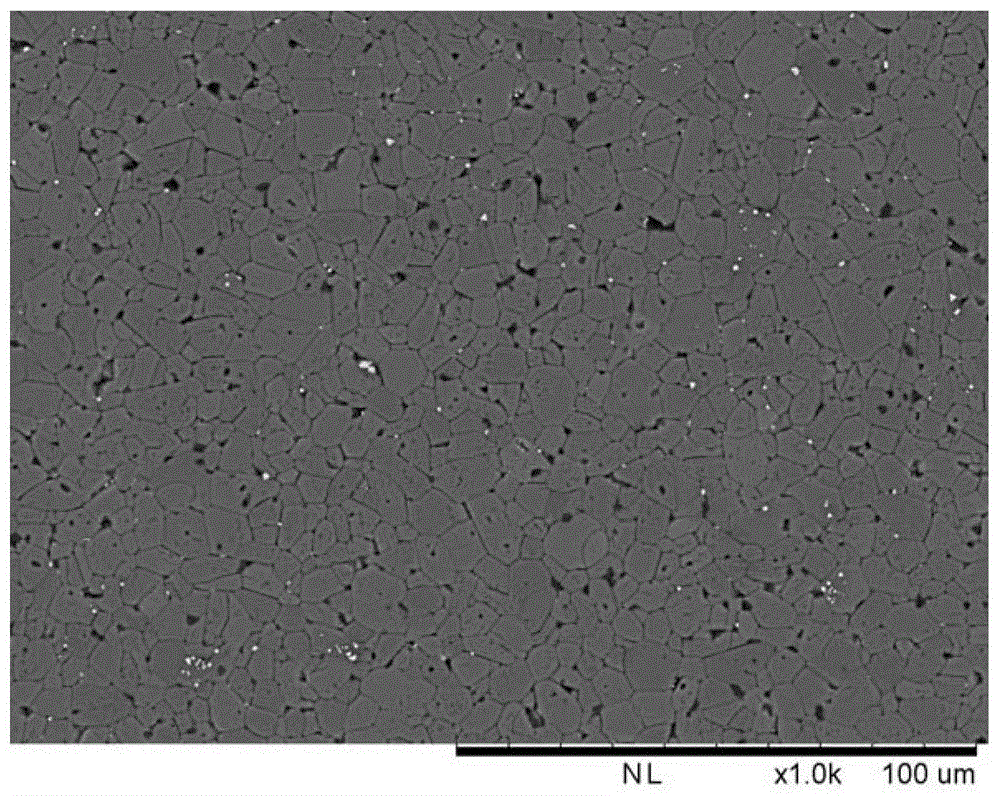

[0063] figure 1 The SEM image of the cross-section of the silicon carbide ceramic prepared by in-situ synthesis of aluminum nitride and carbon as sintering aids for specific example 3, it can be seen that there is a uniformly distributed second phase in the silicon carbide ceramic;

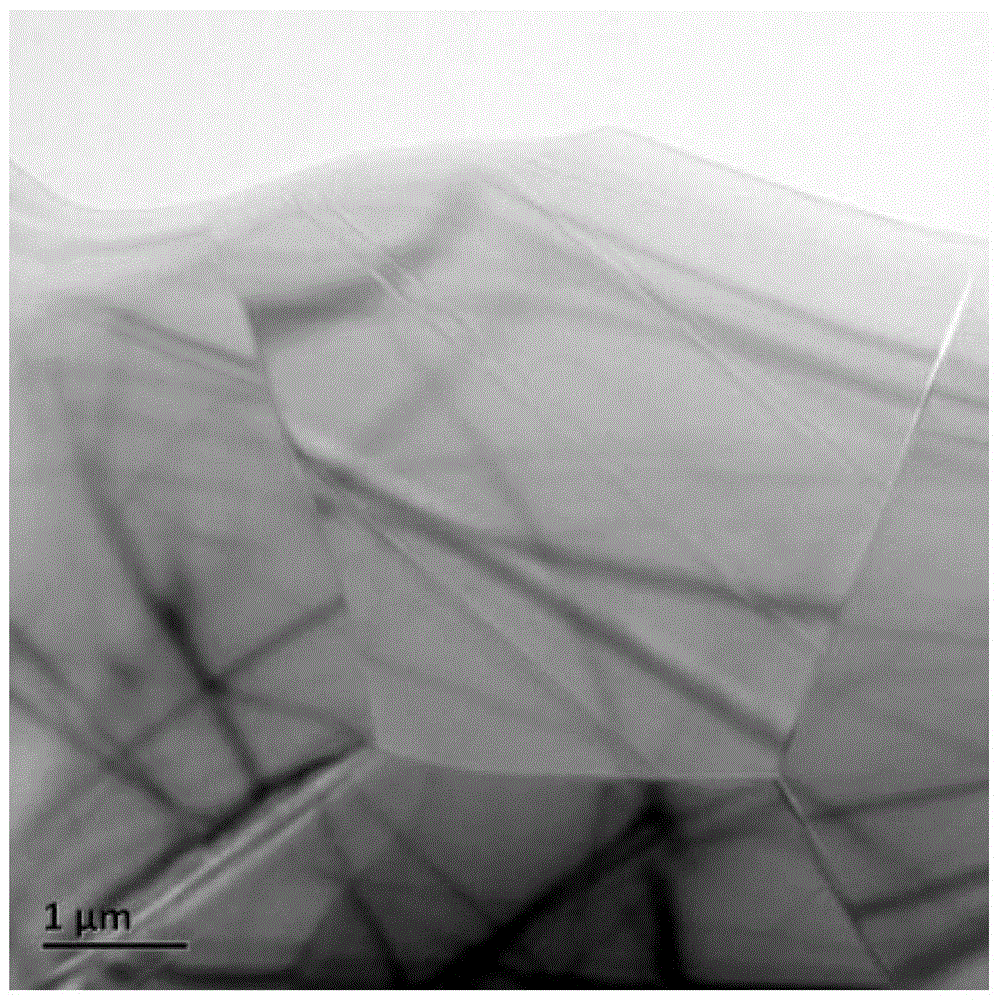

[0064] figure 2 The elemental analysis figure of the silicon carbide ceramics of sintering aids for the in-situ synthesis of aluminum nitride and carbon prepared in specific embodiment 3; from figure 2 It can be seen that silicon carbide ceramics contain Si, Al, C and O elements, and N elements are not detected due to the detection limit. They are all elements with small neutron absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com