A compact type fully hydraulic walking pile-up valve

A fully hydraulic and integrated valve technology, applied in fluid pressure actuation devices, fluid pressure actuation system safety, servo motor components, etc., can solve problems such as excavator or loader safety hazards, large oil noise, and large impact , to avoid the problem of oil suction, avoid pressure shock, and achieve the effect of smooth parking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

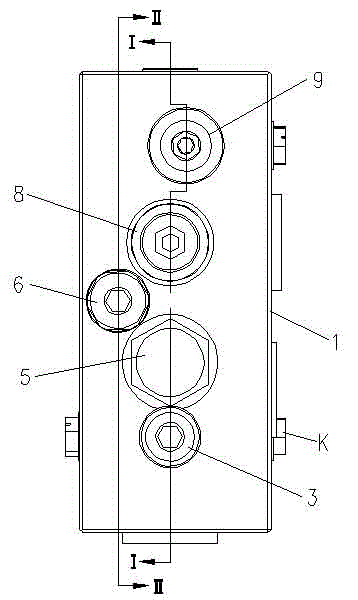

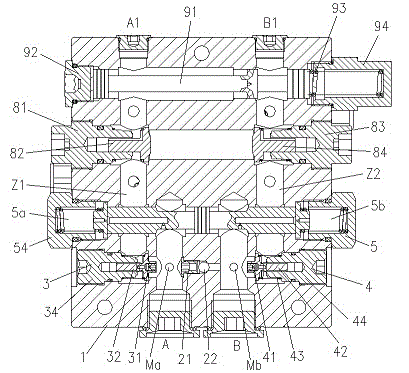

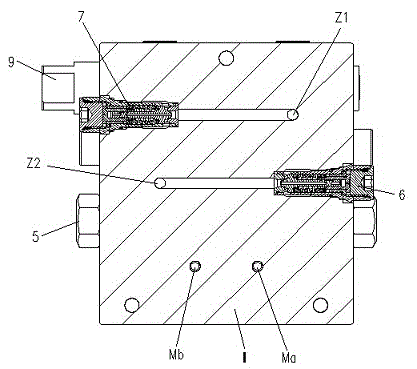

[0030] Figure 1 to Figure 8 It is a structural schematic diagram of the present invention.

[0031] The reference signs are: A port, B port, A1 port, B1 port, C port, T port, K port, Ma port, Mb port, MU port, first main oil passage Z1, second main oil passage Z2 , valve body 1, high-pressure selector valve 2, third damper 2a, threaded check valve seat 21, steel ball 22, first one-way throttle valve 3, first detachable damper 31, first one-way throttle valve Core 32, first one-way throttle valve spring 33, first one-way throttle valve seat 34, second one-way throttle valve 4, second detachable damper 41, second one-way throttle valve core 42, first one-way throttle valve Second one-way throttle valve spring 43, second one-way throttle valve seat 44, balance valve 5, left pilot oil chamber 5a, right pilot oil chamber 5b, first damper 5c, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com