Preparation method of AlN particle enhanced Mg-Al based composite material

A composite material and particle reinforcement technology, applied in the field of metal matrix composite materials, can solve the problems of limited application field and scope, poor wear resistance and high temperature resistance, low elastic modulus of magnesium alloy, etc., and achieve good interface bonding and good mechanical properties. , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

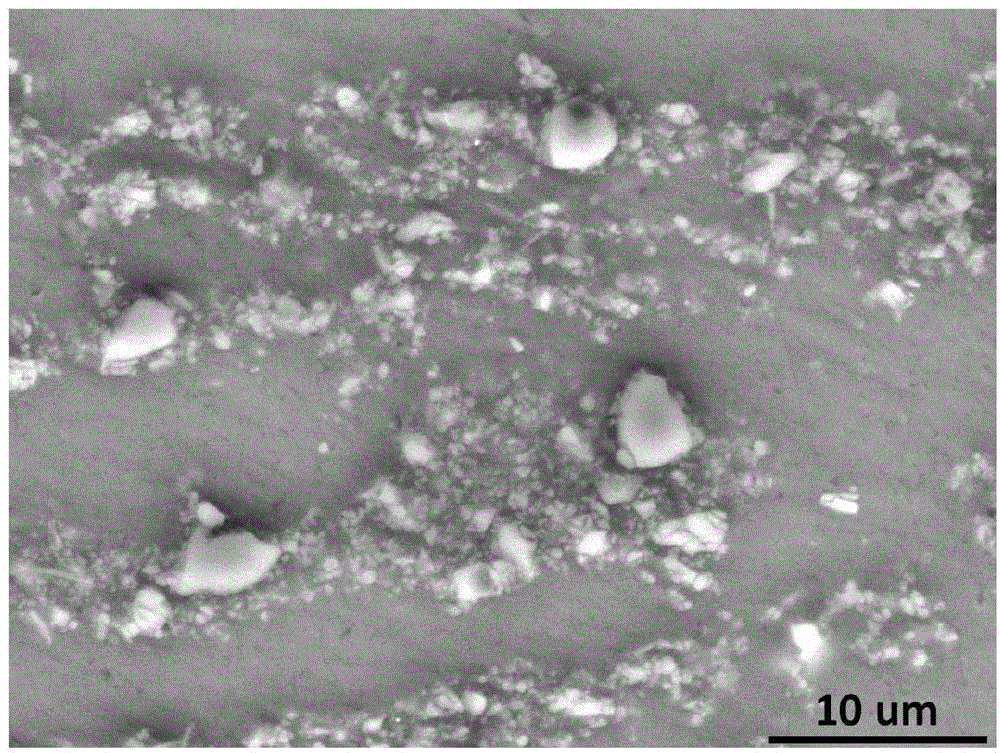

Image

Examples

Embodiment 1

[0016] A method for preparing an AlN particle reinforced Mg-Al matrix composite material, comprising the following steps:

[0017] Step 1, batching design, weigh the three components of 200 mesh magnesium powder, 10um aluminum powder, and 1-3um AlN powder according to the weight ratio of 91:9:5.26, and then weigh 2% of the aforementioned total mass of stearic acid as Process control agent to prevent powder cold welding and make the reinforcement particles more uniformly distributed in the alloy powder;

[0018] Step 2, ball milling, put the powder mixture, stearic acid, and agate balls of two specifications into a 500ml nylon ball milling jar in a glove box protected by pure argon, and mix various powders under the protection of argon For ball milling, fully mix the materials by ball milling on the roller mill for 26 hours, the speed of the roller mill is 85r / min; the two kinds of balls used in the ball milling process are φ10 and φ6 respectively, and the mass ratio of large b...

Embodiment 2

[0023] A method for preparing an AlN particle reinforced Mg-Al matrix composite material, comprising the following steps:

[0024] Step 1, batching design, weigh the three components of 200-mesh magnesium powder, 10um aluminum powder, and 1-3um AlN powder according to the weight ratio of 91:9:11.11, and then weigh the aforementioned 2% stearic acid as the process Control agent to prevent powder cold welding and make the reinforcement particles more evenly distributed in the alloy powder;

[0025] Step 2, ball milling, put the powder mixture, stearic acid, and agate balls of two specifications into a 500ml nylon ball milling jar in a glove box protected by pure argon, and mix various powders under the protection of argon For ball milling, fully ball mill and mix the materials on the roller mill for 24 hours, the speed of the roller mill is 90r / min; the two kinds of balls used in the ball milling process are φ10 and φ6 respectively, and the mass ratio of large balls to small bal...

Embodiment 3

[0030] A method for preparing an AlN particle reinforced Mg-Al matrix composite material, comprising the following steps:

[0031] Step 1, batching design, weigh the three components of 200 mesh magnesium powder, 10um aluminum powder, and 1-3um AlN powder according to the weight ratio of 91:9:17.65, and then weigh the aforementioned 2% stearic acid as the process Control agent to prevent powder cold welding and make the reinforcement particles more evenly distributed in the alloy powder;

[0032] Step 2, ball milling, put the powder mixture, stearic acid, and agate balls of two specifications into a 500ml nylon ball milling jar in a glove box protected by pure argon, and mix various powders under the protection of argon For ball milling, carry out full ball milling and mixing on the roller mill for 30 hours, the speed of the roller mill is 70r / min; the two kinds of balls used in the ball milling process are φ10 and φ6 respectively, and the mass ratio of large balls to small ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com