Preparation method and application of hydrophobic layered bimetallic oxide catalyst

A layered bimetallic and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited catalytic efficiency and easy spontaneous combustion of intermediate products. , to achieve the effect of better dispersion, larger comparison area and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

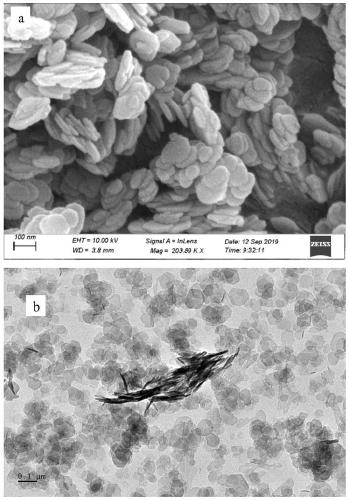

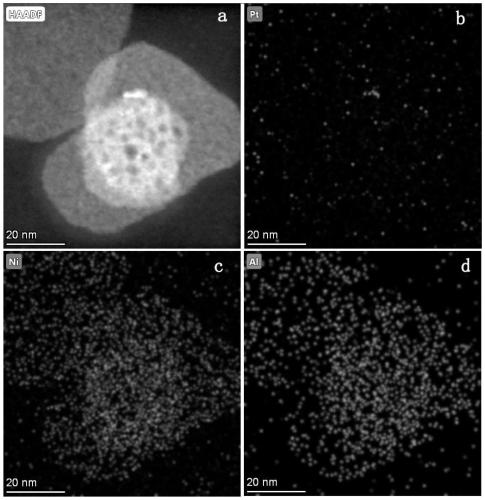

[0043] The first step is the preparation of hydrophobic layered bimetallic oxide catalyst Pt / NiAl-LDO

[0044] Step A1: Add Al(NO 3 ) 3 ·9H 2 O, Ni(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine, PtCl 2 , NaCl was added to deionized water at a molar ratio of 66:33:396:0.1:0.2 and stirred to obtain a mixed solution. Then the mixed solution was transferred to the autoclave and reacted at 150°C for 6 hours to obtain Pt ions. The reduced Pt / NiAl-LDHs catalyst precursor is finally filtered, washed and dried to obtain a powdery Pt / NiAl-LDHs catalyst precursor.

[0045] Step A2: The dry powdered Pt / NiAl-LDHs catalyst precursor obtained in step A1 is heated to 450°C at a heating rate of 3°C / min in an inert atmosphere (nitrogen or argon) protection, and calcined at this temperature After being kept for 2.5 hours, the hydrophobic layered bimetal oxide catalyst Pt / NiAl-LDO is obtained after cooling.

[0046] The second step is the preparation of Pt / NiAl-LDO / PTFE catalyst sheet

[0047] Step B1: first...

Embodiment 2

[0052] The first step is the preparation of hydrophobic layered bimetallic oxide catalyst Pt / NiAl-LDO

[0053] Step A1: Add Al(NO 3 ) 3 ·9H 2 O, Ni(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine, PtCl 2 , NaCl was added to deionized water at a molar ratio of 66:33:792:3:6 and stirred to obtain a mixed solution. Then the mixed solution was transferred to the autoclave and reacted at 180°C for 24 hours to obtain Pt ions. The reduced Pt / NiAl-LDHs catalyst precursor is finally filtered, washed and dried to obtain a powdery Pt / NiAl-LDHs catalyst precursor.

[0054] Step A2: The dry powdered Pt / NiAl-LDHs catalyst precursor obtained in step A1 is heated to 600°C at a heating rate of 8°C / min under the protection of an inert atmosphere (nitrogen or argon), and calcined at this temperature After keeping the temperature for 4 hours, the hydrophobic layered bimetal oxide catalyst Pt / NiAl-LDO is obtained after cooling.

[0055] The second step is the preparation of Pt / NiAl-LDO / PTFE catalyst sheet

[00...

Embodiment 3

[0062] The first step is the preparation of hydrophobic layered bimetallic oxide catalyst Pt / NiAl-LDO

[0063] Step A1: Add Al(NO 3 ) 3 ·9H 2 O, Ni(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine, PtCl 2 , NaCl was added to deionized water at a molar ratio of 66:33:396:1:1 and stirred to obtain a mixed solution. Then the mixed solution was transferred to the autoclave and reacted at 160°C for 18 hours to obtain Pt ion. The reduced Pt / NiAl-LDHs catalyst precursor is finally filtered, washed and dried to obtain a powdered Pt / NiAl-LDHs catalyst precursor.

[0064] Step A2: The dry powdered Pt / NiAl-LDHs catalyst precursor obtained in step A1 is heated to 500°C at a heating rate of 5°C / min in an inert atmosphere (nitrogen or argon) protection, and calcined at this temperature After holding for 3.5 hours, the hydrophobic layered bimetal oxide catalyst Pt / NiAl-LDO is obtained after cooling.

[0065] The second step is the preparation of Pt / NiAl-LDO / PTFE catalyst sheet

[0066] Step B1: first dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com