Surfactant for driving oil

A surfactant and oil displacement technology, which is applied in the field of oil displacement surfactant and oil displacement agent, can solve the problems of high Krafft point, low compatibilization ability, easy to corrode equipment, etc., and achieves wide application prospects and simple process conditions. , the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

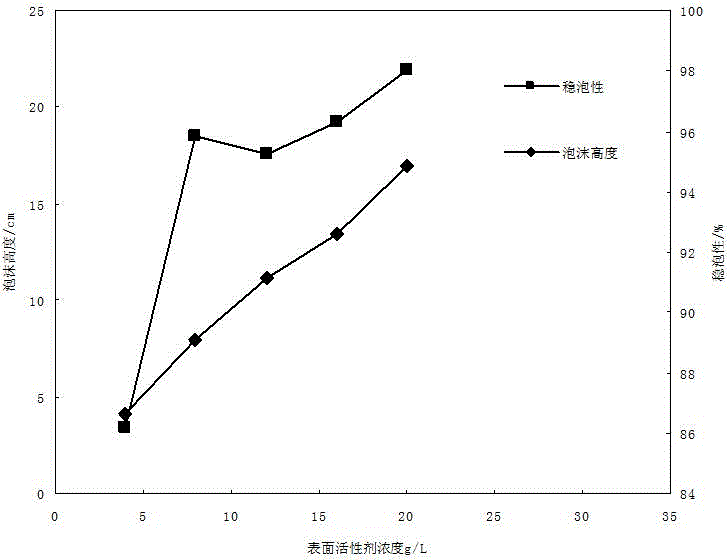

[0035] Surfactant of the present invention has two kinds, single surfactant, i.e. tetramethylethylenediamine tetradecyl allyl dibromide; compound surfactant, i.e. tetradecyl allyl dibromide Tetramethylethylenediamine and sodium monolauryl phthalate are compounded at a mass ratio of 1:0.2-1.

[0036] Wherein tetradecyl allyl dibrominated tetramethylethylenediamine is prepared by the following method,

[0037] 1) Synthesis of Tetramethylethylenediamine Tetradecyl Allyl Dibromide Intermediate

[0038] Add acetonitrile and tetramethylethylenediamine with a volume ratio of 10:1 into the synthesis container, stir evenly, keep the temperature in a water bath at 45°C, and slowly add bromotetradecane, bromotetradecane and tetramethylethylenediamine The molar ratio of diamine is 1:1. After reacting for 2 hours, first distill excess acetonitrile at 80°C under pressure, then raise the temperature to 95°C and continue to distill excess tetramethylethylenediamine under reduced pressure. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com