Preparation method of a self-lubricating copper-carbon pantograph composite material

A composite material and pantograph technology, which is applied in the field of preparation of copper-carbon pantograph composite materials, can solve problems such as unreached performance parameters, achieve simple configuration, high lubrication effect, and increase the effect of graphite lubrication area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

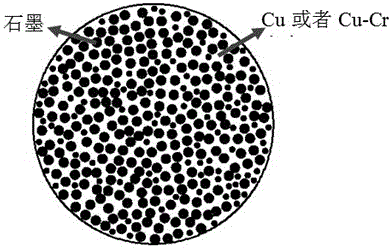

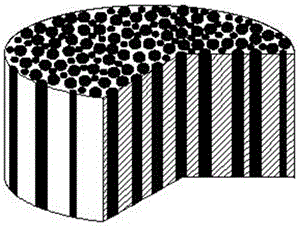

[0022] The preparation method of the self-lubricating copper-carbon pantograph composite material described in this embodiment specifically comprises the following steps:

[0023] (1) Porous copper-chromium alloy prepared by Gasar technology (parameters: hydrogen pressure 6atm, holding temperature 1150°C, holding time 5min) as raw material (its characteristic parameters are: composite material density ρ =3.75g / cm 3 , the average diameter of the pores is 0.63mm, and the porosity is 43%; the friction coefficient of the 300N load and the 45# steel friction pair is μ=0.035, and the total area ratio of the cross-section pores is 15%), cleaning (use 1% concentration of the porous matrix Nitric acid solution cleaning for 5 minutes, cleaning in the ultrasonic tank, after cleaning, take it out and put it in 99.9% alcohol for 5 minutes), dry it and set it aside;

[0024] (2) Adhesive (a mixture obtained by mixing PVB solution and FB type thermosetting resin at a mass ratio of 8:3, wit...

Embodiment 2

[0027] The preparation method of the self-lubricating copper-carbon pantograph composite material described in this embodiment specifically comprises the following steps:

[0028] (1) Select porous pure copper with a purity of 99.9% prepared based on Gasar technology (parameters: hydrogen pressure 1atm, holding temperature 1100°C, holding time 10min) (its characteristic parameters are: porosity 50%, cross-sectional hole The total area ratio is 30%, and the average pore diameter is 1.7mm) is a porous substrate, and it is cleaned (clean the porous substrate with a 3% nitric acid solution for 10 minutes, and the cleaning is carried out in an ultrasonic tank, and after cleaning, take it out and put it in 99.9% alcohol After cleaning for 10 minutes), dry and set aside;

[0029] (2) Adhesive (a mixture obtained by mixing PVB solution and FB type thermosetting resin at a mass ratio of 9:3, with a mass ratio of 2:1, and the PVB solution mass percentage concentration is 5%) Mix unifor...

Embodiment 3

[0032] The preparation method of the self-lubricating copper-carbon pantograph composite material described in this embodiment specifically comprises the following steps:

[0033] (1) Select porous pure copper with a purity of 99.99% prepared based on Gasar technology (hydrogen pressure 6atm, holding temperature 1200°C, holding time 1min) (its characteristic parameters are: porosity 60%, total area ratio of cross-sectional pores 40%, the average pore diameter is 1.2mm) is a porous substrate, cleaning (cleaning the porous substrate with 5% nitric acid solution for 15 minutes, cleaning in an ultrasonic tank, taking it out after cleaning, putting it in 99.9% alcohol and cleaning it for 15 minutes minutes), dried for later use;

[0034] (2) Adhesive (a mixture obtained by mixing PVB solution and FB type thermosetting resin at a mass ratio of 10:3, with a mass ratio of 3:2, and its PVB solution mass percentage concentration is 7%) After uniformly mixing with graphite (10000 mesh) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com