Spray drying desulfurizer used for cement plant and process method

A cement plant and drying technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high cost of desulfurizers, high equipment operation and maintenance costs, and high operating costs, and achieve obvious environmental and social benefits. Significant economic and energy-saving benefits, and the effect of low desulfurizer consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

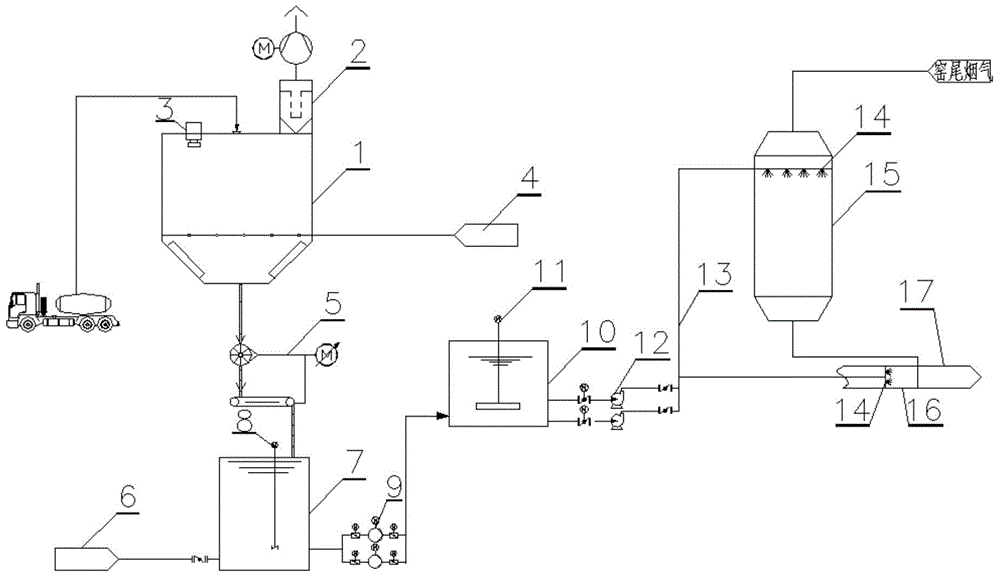

[0029] Such as figure 1 As shown, a smoke spray drying and desulfurization device used in a cement plant of the present invention mainly includes a quicklime storage system, a quicklime digestion system, a desulfurizer storage and delivery system, and an injection system.

[0030] 1. Quicklime storage system

[0031] Purchase the quicklime powder that meets the needs of the system, and transport it from the tank truck to the quicklime storage silo 1, and the powder tank truck is equipped with an air compressor for unloading. There is a sealed inspection manhole door on the top of the quicklime storage bin 1. Doors will open quickly with hinges and handles. The quicklime storage bin 1 is equipped with a dust removal device 2, and the maximum dust content in the clean gas does not exceed 30mg / Nm 3 . The quicklime storage bin 1 is equipped with a material level gauge 3 for determining the volume, and can also be used for remote indication. For the inspection and maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com