Cooling method and cooling device for hot-rolled steel strip

一种冷却装置、冷却方法的技术,应用在工件冷却装置、金属轧制、金属轧制等方向,能够解决刚性弱、困难、易弹起或卷起等问题,达到简便冷却速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] The embodiment of the present invention is explained.

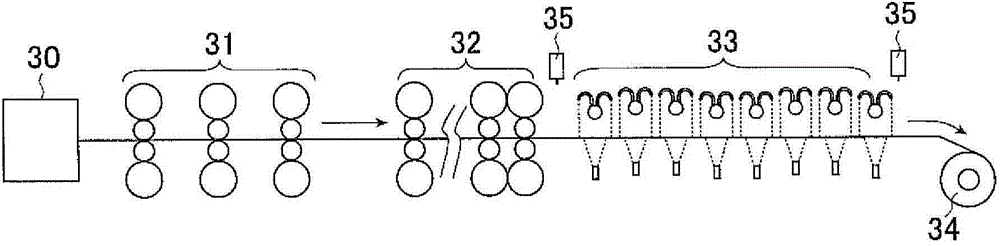

[0096] In this embodiment, in figure 1 On the hot-rolled steel strip manufacturing production line, the billet with a plate thickness of 250mm is heated to 1200°C in the heating furnace 30, and then rolled into a plate thickness of 3.2mm and a plate width of 1200mm through the rough rolling mill 31 and the finishing mill 32. The device 33 is cooled, and the winding is performed by the winding machine 34. The temperature after the end of rolling and after the end of cooling was measured with a radiation thermometer 35. The temperature after rolling was 850°C, and the temperature after cooling was 550°C. Furthermore, the speed of the steel strip during cooling is 550 mpm.

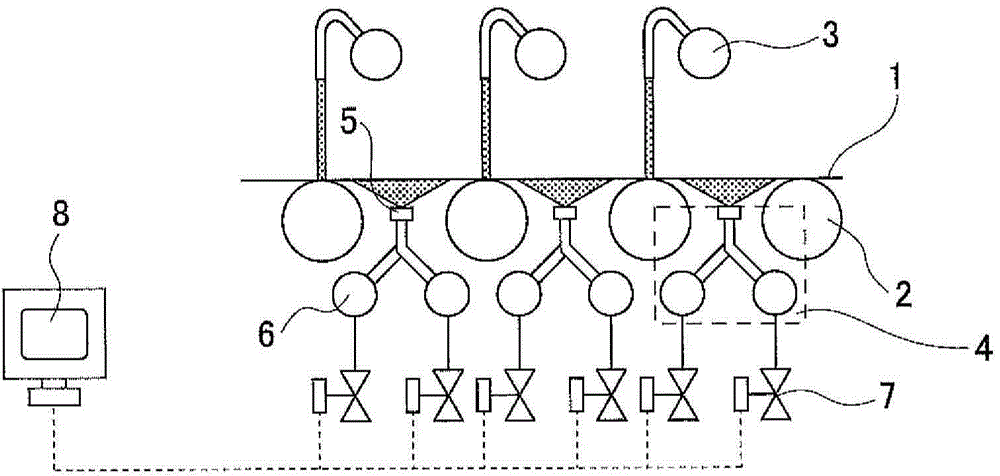

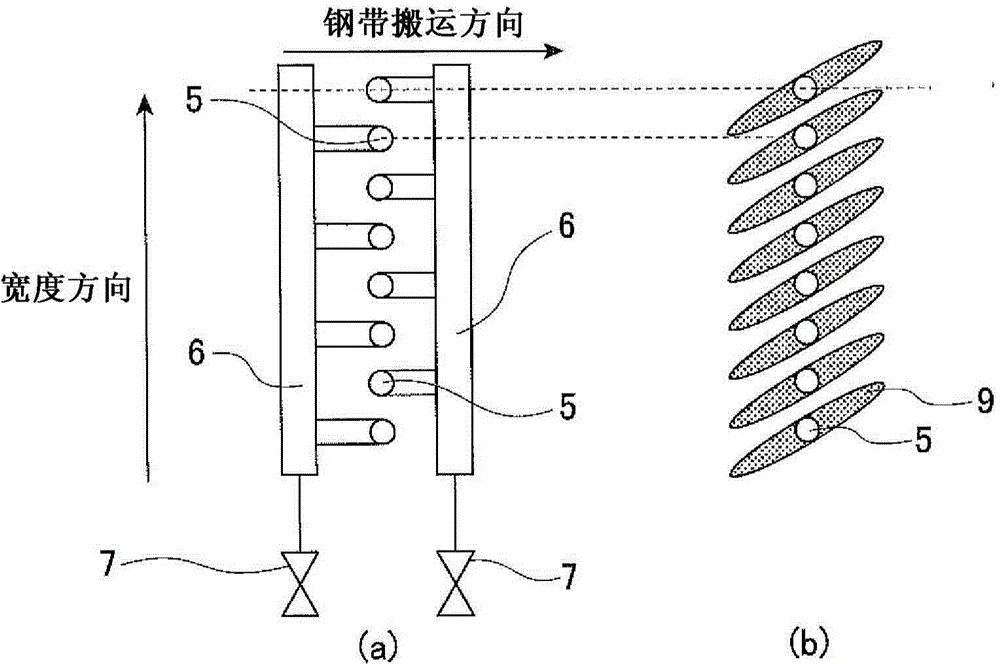

[0097] Cooling device 33 such as figure 2 In that way, the upper surface is set as the tube laminar flow nozzle 3, and the lower surface is set as the spray cooling 4 of the present invention. The flow density of injection per unit area is 1000L / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com