Gasification method for coproducing methane and light-weight tar

A technology for light tar and methane gas, which is used in granular/powder fuel gasification, petroleum industry, gas fuel, etc., and can solve the problems of heavy tar component proportion, low coal tar output, and low economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

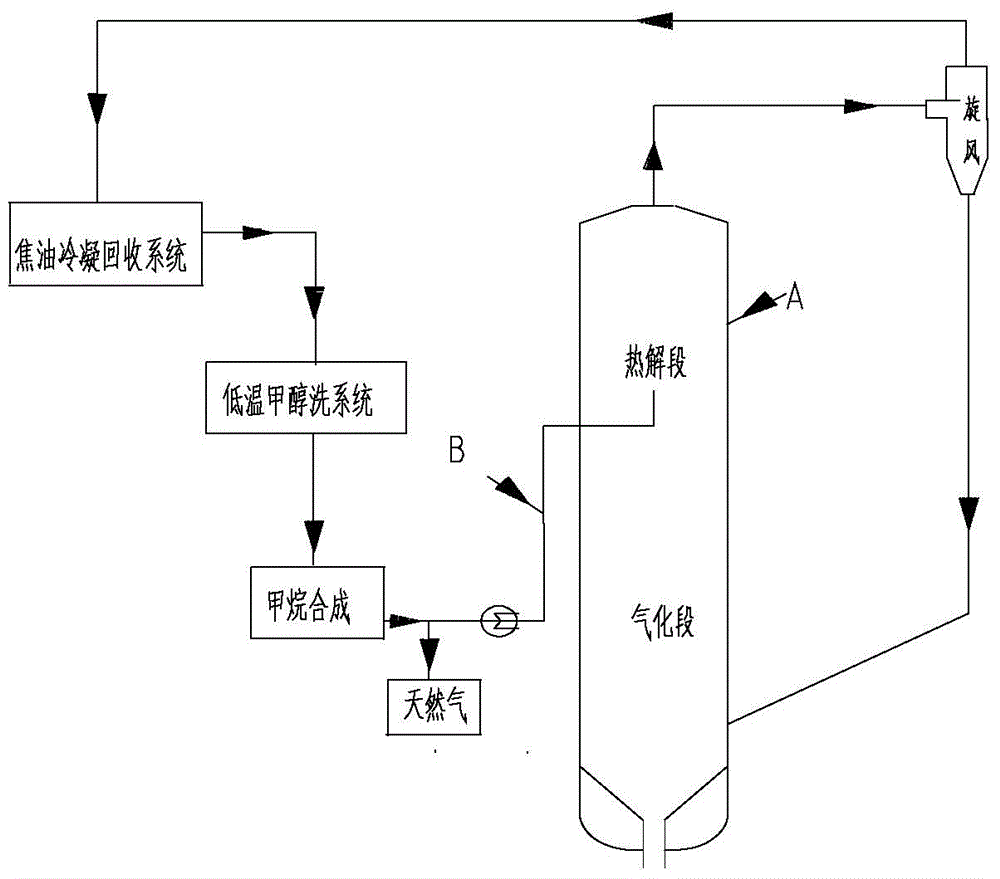

[0056] Such as figure 2 As shown, a two-stage fluidized bed gasifier is used, and the diameter ratio of the pyrolysis section to the gasification section is 1. A certain bituminous coal enters the pyrolysis section of the gasifier through the feed port A after the catalyst loading process. After being upgraded in the pyrolysis section, it falls into the gasification section of the gasifier for gasification reaction. The high-concentration methane synthesis gas produced by the catalytic gasification section and the gas and tar produced by the pyrolysis section are discharged from the top of the gasifier, and enter the tar condensation recovery system after cyclone dust removal, and the tar in the gas is separated, and then enters the The low-temperature methanol washing section removes acid gases such as hydrogen sulfide and carbon dioxide, and then enters methane synthesis to obtain high-concentration methane gas (methane content above 96%). Among them, a small part of high-c...

Embodiment 2

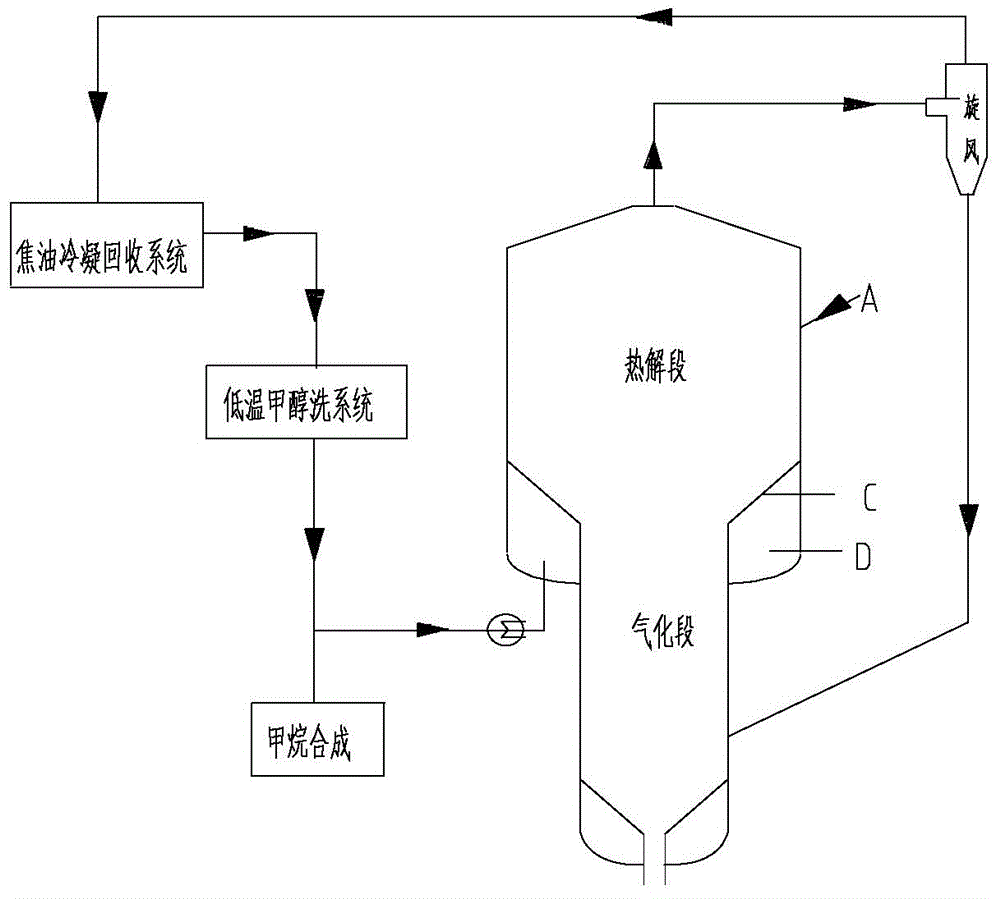

[0060] Such as image 3 As shown, a two-stage gasifier is used, and the diameter ratio of the pyrolysis section to the gasification section is 2. A certain bituminous coal enters the pyrolysis section of the gasifier through the feed port A after the catalyst loading process. After being upgraded in the pyrolysis section, it falls into the gasification section of the gasifier for gasification reaction. The high-concentration methane synthesis gas produced by the gasification section and the gas and tar produced by the pyrolysis section are discharged from the top of the gasification furnace, and enter the tar condensation recovery system after cyclone dust removal. After the tar is separated, it enters the low-temperature methanol washing section. Remove acid gases such as hydrogen sulfide and carbon dioxide to obtain methane-containing gas (containing hydrogen 50-55%, methane 28-35%, carbon monoxide 15-18%), and a small part of methane-containing gas returns to the gasifier a...

Embodiment 3

[0064] use Figure 4 Two-stage gasification furnace structure, the diameter ratio of the pyrolysis section and the gasification section is 1. A lignite enters the pyrolysis section of the gasifier through the catalyst loading process through the feed port A. After being upgraded in the pyrolysis section, it falls into the gasification section of the gasifier for gasification reaction. The high-methane-concentration syngas produced by the catalytic gasification section, together with the gas and tar produced by the pyrolysis section, are discharged from the top of the gasifier, and enter the tar condensation recovery system after cyclone dust removal, and part of high-quality superheated steam is generated through heat exchange. The gas from the tar condensation recovery outlet enters the low-temperature methanol washing section, and then undergoes methane synthesis. The high-quality superheated steam obtained by heat exchange is synthesized with methane to obtain high-concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com