Porous phosphorus removal ceramisites and preparation method thereof

A technology for ceramsite and crop straw, which is applied in the field of porous phosphorus removal ceramsite and its preparation to achieve the effects of shortening adsorption time, increasing mass transfer rate and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of porous phosphorus-removing ceramsite specifically includes the following steps: (1) Ingredients: Weigh 70 parts of attapulgite, 20 parts of corn stalks, and 10 parts of lanthanum carbonate in parts by weight, and first crush the corn stalks with a pulverizer , and then mix the raw materials, wherein attapulgite is used as the main material, which itself has a certain adsorption capacity, which can realize the reasonable development of attapulgite, granulate into balls and sinter, and absorb phosphorus for easy recovery; (2) Blank making: According to the mass ratio of water to the above mixture of 1:0.45 to make ceramsite blanks; (3) Sintering: Dry and sinter the ceramsite blanks, preferably at 100°C for 25min, then raise the temperature to 700°C, the heating rate 2-4°C / min is appropriate, and sintered at this temperature for 30 minutes to obtain a sintered product; (4) Cooling: cooling the above sintered product to obtain porous phosphorus-remo...

Embodiment 2

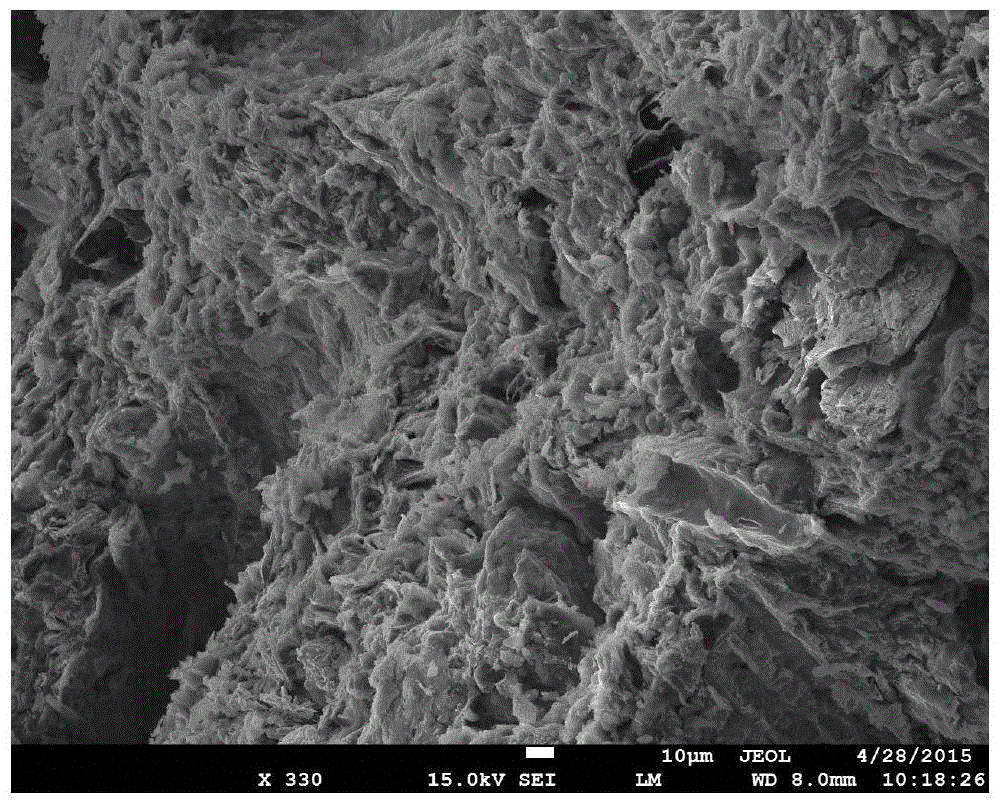

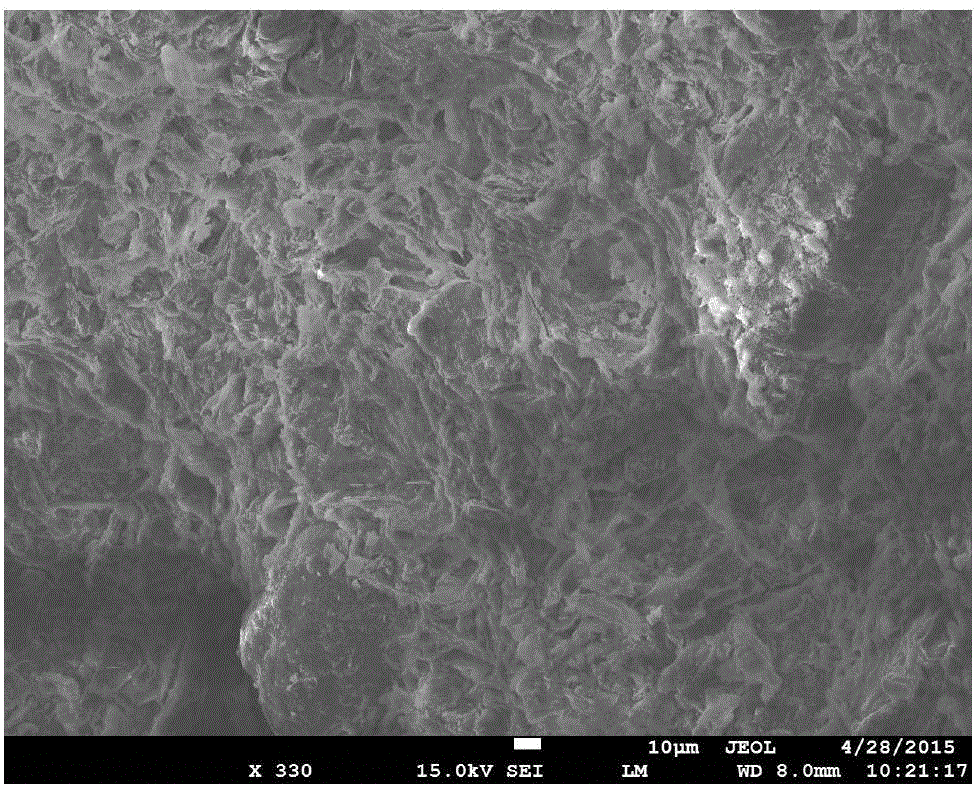

[0033]The preparation method of porous phosphorus-removing ceramsite specifically includes the following steps: (1) Ingredients: Weigh 80 parts of attapulgite, 10 parts of rice straw, and 10 parts of lanthanum carbonate in parts by weight, and first crush the corn straw with a pulverizer , and then mix the raw materials. Among them, the rice straw is rich in fibrous tissue, which is transformed into activated carbon during the sintering process, which can endow the ceramsite with a porous structure, improve the mass transfer efficiency, and also enhance the adsorption capacity of phosphorus; (2) Blank making: According to the mass ratio of water and the above mixture to make ceramsite blanks; (3) Sintering: Dry and sinter the ceramsite blanks, preferably at 200°C for 30min, then heat up to 600°C and sinter for 40min to obtain Sintered product; (4) cooling: cooling the above-mentioned sintered product to obtain porous phosphorus-removing ceramsite. The SEM photographs of the pr...

Embodiment 3

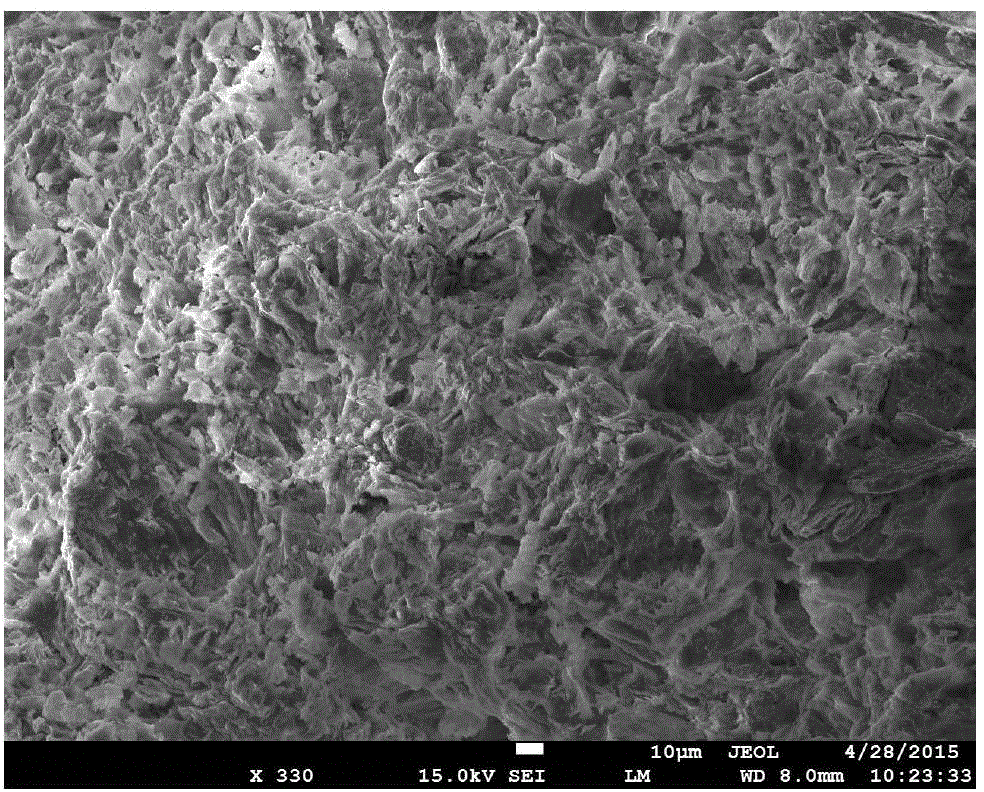

[0037] The preparation method of porous phosphorus-removing ceramsite specifically includes the following steps: (1) Ingredients: Weigh 55 parts of attapulgite, 25 parts of rapeseed straw, and 20 parts of lanthanum carbonate in parts by weight, and first crush the rapeseed straw with a pulverizer , and then mix the raw materials; (2) Billet making: according to the mass ratio of water to the above mixture of 1:0.5 to make ceramsite billets; (3) sintering: dry and sinter the ceramsite billets, preferably at 120°C for heat preservation After 45 minutes, heat up to 650°C and sinter for 60 minutes to obtain a sintered product; (4) Cooling: Cool the above sintered product to obtain porous phosphorus-removing ceramsite. The SEM photographs of the prepared porous phosphorus-removing ceramsite are as follows: image 3 As shown, the interior of the ceramsite presents a rough and uneven pore structure, which is conducive to enhancing the adsorption capacity of phosphorus, thereby enhanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com