Formulation and processing method of cutting disc for titanium alloy

A processing method and technology of cutting discs, which are applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve problems such as poor anti-aging performance, excessive consumption of cutting discs, and insufficient safety performance, so as to facilitate smooth feeding and improve Anti-aging performance, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

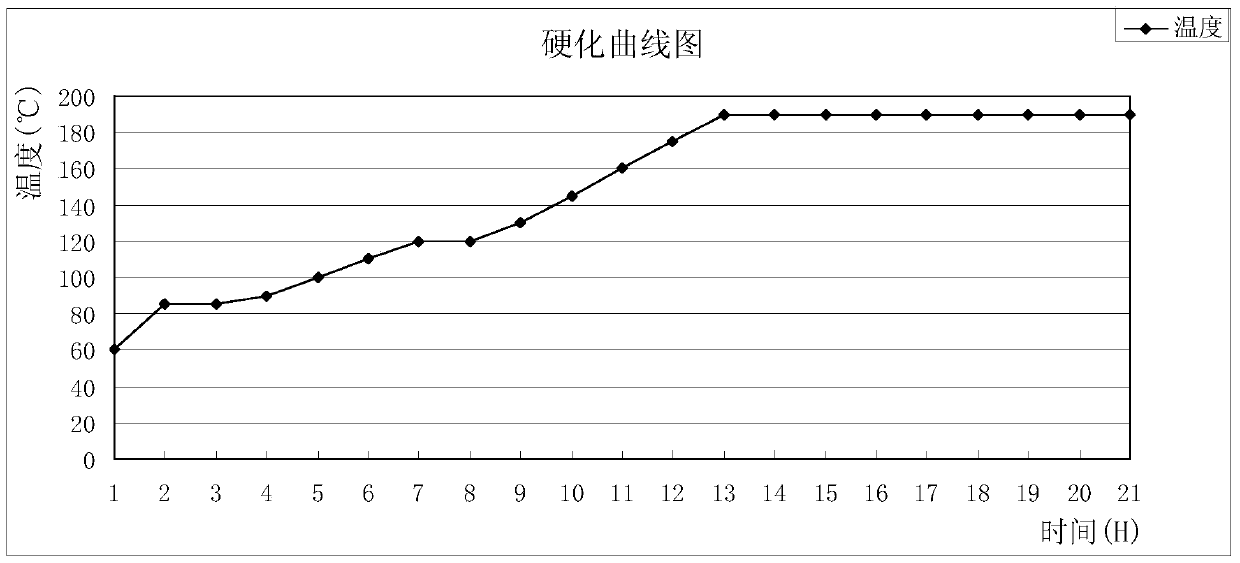

[0028] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

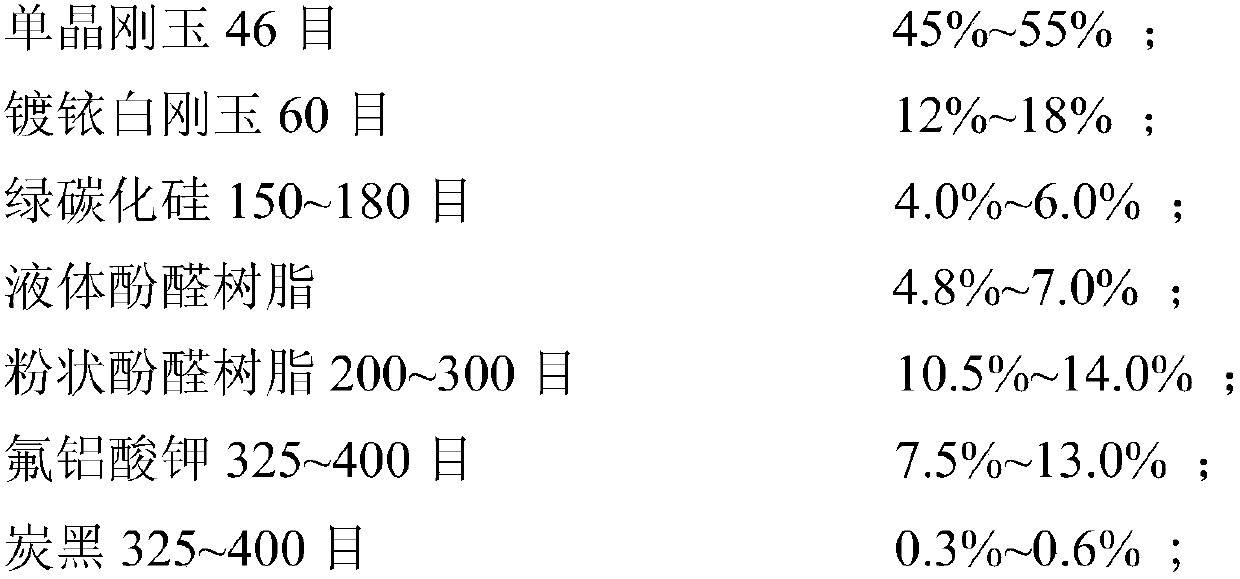

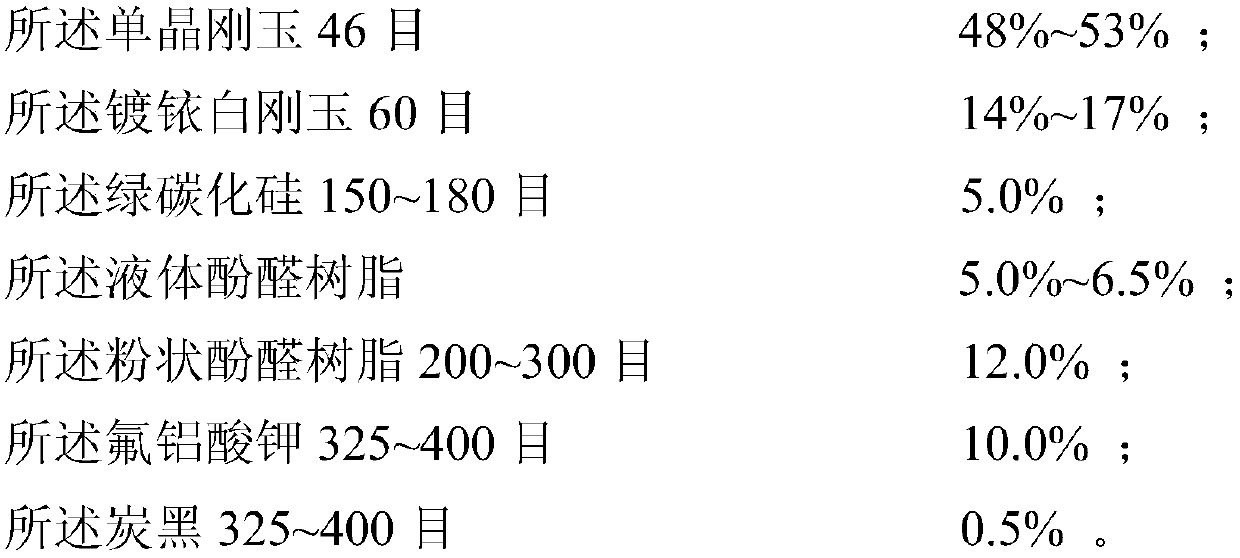

[0029] The formulation of a cutting sheet for titanium alloy described in the embodiment of the present invention, the formulation includes: 40% to 60% of single crystal corundum with a particle size of 46 mesh; 10% to 20% of iridium-coated white corundum with a particle size of 60 mesh; Green silicon carbide with a particle size of 150-180 mesh 2.0%-8.0%; liquid phenolic resin with a viscosity of 1800-2000mPa·s (25°C) 4.5%-7.5%; powdered phenolic resin with a particle size of 200-300 mesh 9.0%-15.0% ; 5.0% to 15.0% of potassium fluoroaluminate with a particle size of 325 to 400 mesh; 0.2% to 0.8% of carbon black with a particle size of 325 to 400 mesh is added as a colorant. The above materials are mixed according to a specific process to make outer diameter (D) 75mm-230mm, thickness (T) 0.8mm-2.0mm, aperture (H) 9.6mm-22.2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com