Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

A copper-nickel sulfide ore and magnesium oxide technology, applied in flotation, solid separation, etc., can solve the problems of concentrate grade decline, smelting process difficulties, gangue minerals are difficult to effectively suppress, etc., and achieve the effect of improving metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

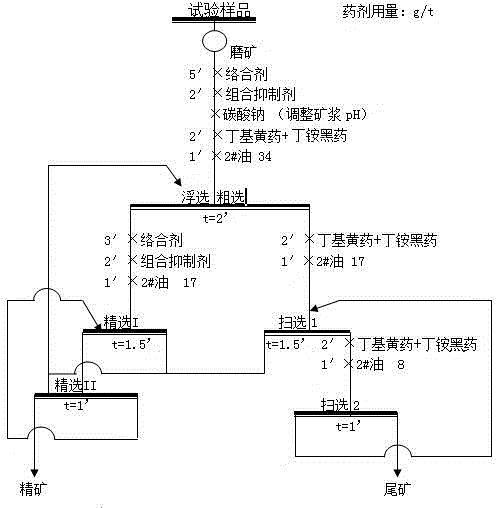

Method used

Image

Examples

example 1

[0022] Example 1 : The low-grade nickel ore was collected from the Longshou mining area in Jinchuan, Gansu, with a Ni content of 0.74% and a Cu content of about 0.58%, which is a lean ore. First, grind the raw ore until the particle size is -0.074mm and the content is 88%, then put the ore slurry into the flotation stirring tank, add complexing agent citric acid to the stirring tank, the dosage is 1000g / t, and stir for 5 minutes; then Add 500g / t of sodium hexametaphosphate and 200g / t of gull gum combined inhibitor to the stirring tank, stir for 2 minutes; add a certain amount of sodium carbonate, adjust the pH value of the pulp to about 9.5; finally add the collector butyl Xanthate 50g / t, butylamine black medicine 50g / t, laboratory closed-circuit process test, the test results are shown in Table 1.

[0023] Table 1

[0024]

example 2

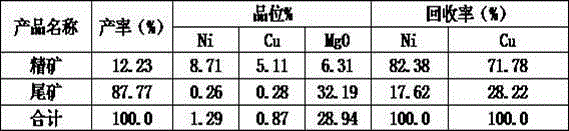

[0026] The original nickel ore was collected from the Longyi mining area in Jinchuan, Gansu, with a Ni content of 1.29% and a Cu content of 0.87%. First, grind the ore until the particle size is -0.074mm and the content is 87.58%, then put the ore pulp into the flotation stirring tank, add complexing agent EDTA to the stirring tank, the dosage is 1500g / t, and stir for 5 minutes; Use 300g / t sodium hexametaphosphate and 150g / t chitosan combined inhibitor in the stirring tank, stir for 2 minutes; add a certain amount of sodium carbonate, adjust the pH value of the pulp to about 9.5; finally add the collector butyl yellow Drug 60g / t, butylamine black drug 60 / t, laboratory closed-circuit process test, the test results are shown in Table 2.

[0027] Table 2

[0028]

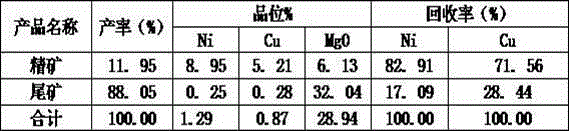

example 3

[0030] The original nickel ore was collected from the Longyi mining area in Jinchuan, Gansu, with a Ni content of 1.29% and a Cu content of 0.87%. First, grind the raw ore until the particle size is -0.074mm and the content is 88.67%, then put the ore slurry into the flotation stirring tank, add complexing agent oxalic acid to the stirring tank, the dosage is 2000g / t, and stir for 5 minutes; Use 400g / t sodium hexametaphosphate and 200g / t chitosan combined inhibitor in the stirring tank, stir for 2 minutes; add a certain amount of sodium carbonate, adjust the pH value of the pulp to about 9.5; finally add the collector butyl yellow Drug 60g / t, butylamine black drug 60 / t, laboratory closed-circuit process test, the test results are shown in Table 3.

[0031] table 3

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com