Carbon dioxide corrosion-resistant pipeline steel and preparation method thereof

A technology of carbon dioxide and pipeline steel, which is applied in the field of pipeline steel and its manufacturing, can solve problems such as early corrosion failure, pipeline pitting and perforation, and shortened service life of pipelines, and achieve good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

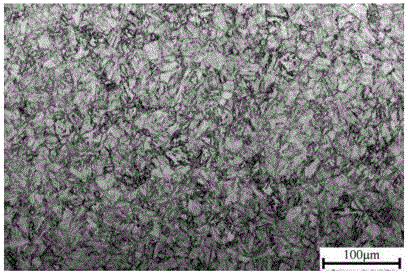

Image

Examples

specific Embodiment

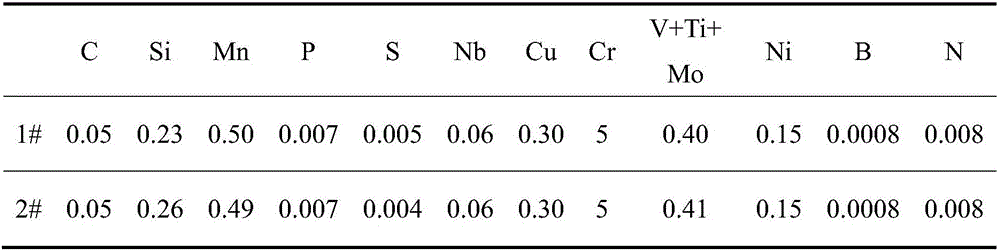

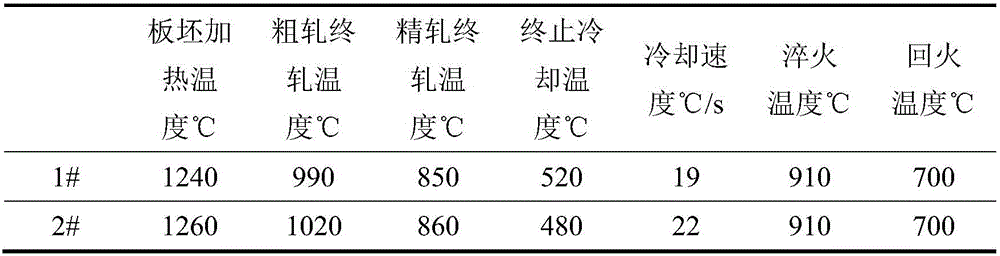

[0054] See Table 1-1 for the chemical composition mass ratios of the carbon dioxide corrosion-resistant pipeline steel examples, and the specific implementation methods of the examples include the following steps:

[0055] The first step is to smelt and cast steel billets according to the above composition and put them into the heat preservation pit to cool slowly to room temperature;

[0056] The second step, heating: the billet is heated at 1100°C to 1250°C, and kept for 2 to 3 hours to ensure the uniformity of the temperature and structure of the billet;

[0057] The third step, rough rolling: the rough rolling temperature is guaranteed to be between 940-1100°C, and the cumulative reduction rate is 65-75%;

[0058] The fourth step, finish rolling: the finish rolling temperature is guaranteed to be between 800-920°C, and the cumulative reduction rate is 60-70%;

[0059] The fifth step, cooling: the cooling rate is 10-30°C / s, and the final cooling temperature is in the range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com