Chemical core cutting wire for underwater wet method electric arc cutting

A technology of arc cutting and wet method, which is applied in the direction of welding/cutting medium/material, welding medium, metal processing equipment, etc. It can solve the problems of limiting the practical application of cutting wire, stainless steel does not work, and difficult to remove slag from the cutting edge, etc., to achieve Light weight, simple production, easy to remove slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

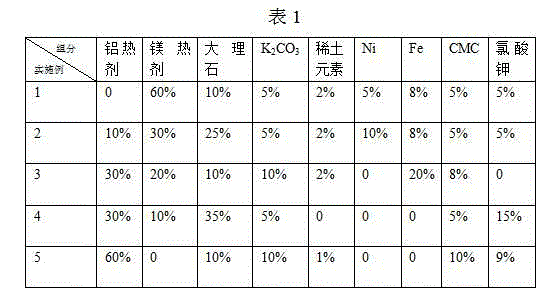

Examples

preparation example Construction

[0013] The preparation method of the drug core cut wire of the present invention is to select an O-state 1060 pure aluminum strip with a width of 8mm and a thickness of 0.3mm. Made by a wire drawing machine, the cross-section of the drug core cut wire is 'O' shape, and the cut wire diameter is 2.0mm.

[0014] Among the chemical components of the above-mentioned internal drug core, the content and mechanism of action of each component are as follows:

[0015] In the present invention, the thermite and magnesium thermite are the components with more content, they react under the high temperature of the arc heat, and release more heat, and the auxiliary arc melts the metal to be cut. In the present invention, the thermite and magnesium The adding amount of heating agent is 40-60%.

[0016] In the present invention, the added marble mainly plays the role of gas generation. When cutting underwater, the gas released by the marble plays the role of protecting the cutting edge. The a...

Embodiment 1

[0023] The drug core component of Example 1 is used to prepare the drug core cutting wire. Under the conditions of cutting current 250-290A and voltage about 40V, the 8mm thick Q235 steel plate is cut underwater, and a cut with good quality can be obtained, and the cut is easy to clean. scum.

Embodiment 2

[0024] The drug core component of Example 2 was used to prepare drug core cutting wire. Under the conditions of cutting current 180-210A and voltage about 40, the 5mm thick 304 stainless steel was cut underwater to obtain a cut with good quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com