Preparation device and preparation method of metal semi-solid billets

A preparation device and semi-solid technology, which is applied in the field of metal materials and metallurgy, can solve the problems of inability to use semi-solid blanks to prepare effects, complex equipment structure and operation, and high investment costs, and achieve low cost, simple preparation devices and process operations, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

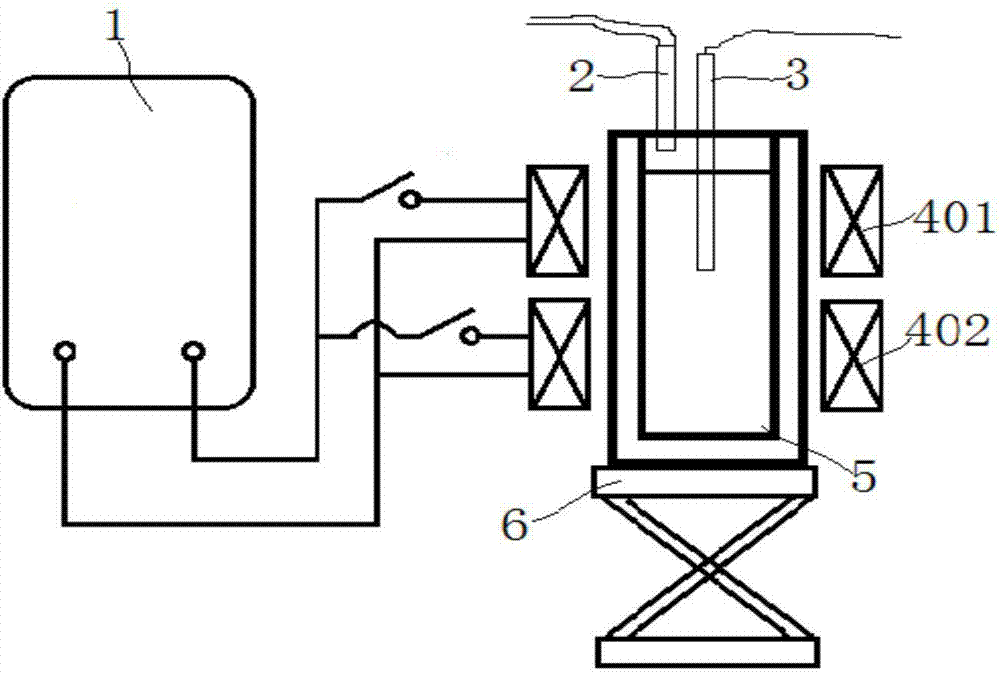

[0043] Such as figure 1 As shown, the preparation device of a metal semi-solid blank in this embodiment includes a heating mechanism, a crucible 5 and a lifting platform 6, wherein the above-mentioned heating mechanism includes an AC power supply 1 and a heating coil, and the heating coil is connected to the AC power supply 1 through a wire , and the heating coil includes a first coil 401 and a second coil 402, the first coil 401 and the second coil 402 are connected in parallel, and the first coil 401 is located above the second coil 402; the crucible 5 is fixed on the lifting platform 6 and placed inside the first coil 401 and the second coil 402. The top of the crucible 5 is provided with a protective gas inlet 2 and a mounting hole through which a thermocouple 3 is fixed, and the sensing end of the thermocouple 3 extends into the inside of the crucible 5 .

[0044] The preparation method of a metal semi-solid blank in this embodiment includes conventional smelting, refini...

Embodiment 2

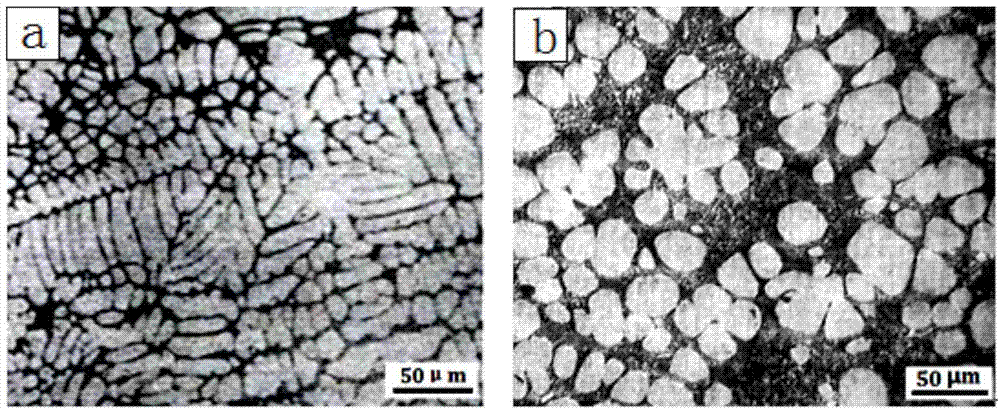

[0052] The preparation method of a metal semi-solid billet in this embodiment includes conventional smelting, refining treatment and cyclic remelting treatment procedures, wherein smelting, refining and cyclic remelting treatment all adopt figure 1 A device for preparing metal semi-solid blanks. In this embodiment, AZ91 magnesium alloy is selected as the test material, its liquidus temperature is 597°C, and its solidus temperature is 473°C. use figure 1 When preparing the semi-solid billet of the magnesium alloy in this embodiment, the AZ91 magnesium alloy is first placed in the crucible 5, and the first coil 401 and the second coil 402 are used to heat it to a molten state, and at 720 ° C Next, the metal melt is refined. After the refining process is completed, the subsequent cyclic remelting process is carried out on the magnesium alloy metal melt, and the protective gas inlet 2 is introduced during the entire process of smelting, refining and cyclic remelting. 2% SF 6 +C...

Embodiment 3

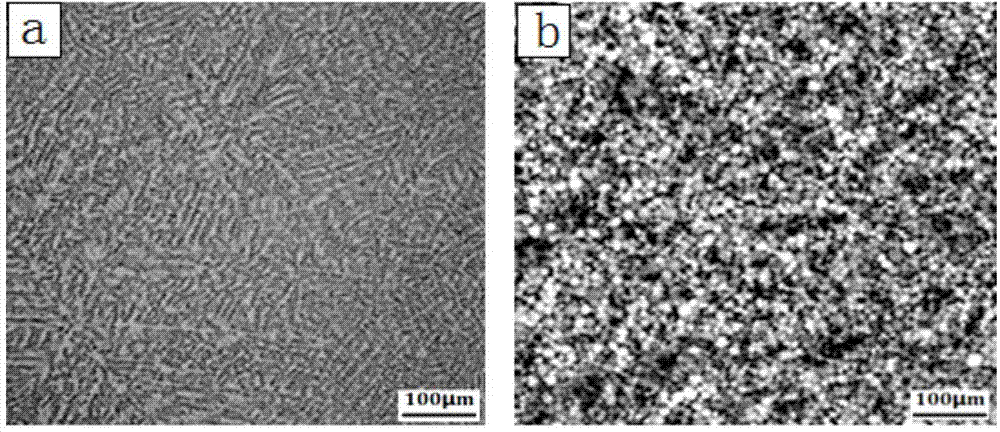

[0060] The preparation method of a metal semi-solid billet in this embodiment includes conventional smelting, refining treatment and cyclic remelting treatment procedures, wherein smelting, refining and cyclic remelting treatment all adopt figure 1 A device for preparing metal semi-solid blanks. In this embodiment, T10 tool steel is selected as the test material, its liquidus temperature is 1480°C, and its solidus temperature is 1350°C. use figure 1 When preparing the semi-solid blank of T10 tool steel in this embodiment, the T10 tool steel is first placed in the crucible 5, while using the first coil 401 and the second coil 402 to heat it to a molten state, and at 1600 The metal melt is refined at ℃, and after the refining process is completed, the T10 tool steel metal melt is subjected to subsequent cyclic remelting treatment process, and the protective gas is imported 2 during the whole process of smelting, refining and cyclic remelting treatment Into 2% SF 6 +CO 2 Mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com