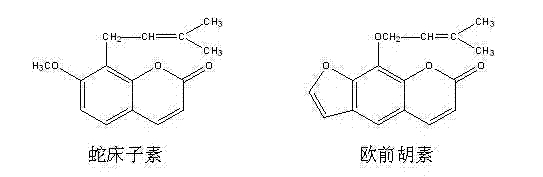

Method for separating and purifying cnidium lactone and imperatorin from fructus cnidii

An osthole, separation and purification technology, applied in the chemical and pharmaceutical fields, can solve the problems of high recovery cost of organic solvents, difficult to expand the separation scale, difficult solvent system selection, etc., and achieve a short process cycle, easy automatic control, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 500 grams of Fructus Cnidii, pulverize it with a pulverizer, put it in a glass container, add 2500ml of absolute ethanol to extract by cold soaking for 12 hours, extract 3 times, filter the extract, concentrate under reduced pressure to obtain an extract, and disperse the extract in 500ml of water, extracted 3 times with 500ml of petroleum ether. The combined petroleum ether extracts were distilled under reduced pressure to recover the petroleum ether to obtain Cnidium Fructus Cnidii Extract.

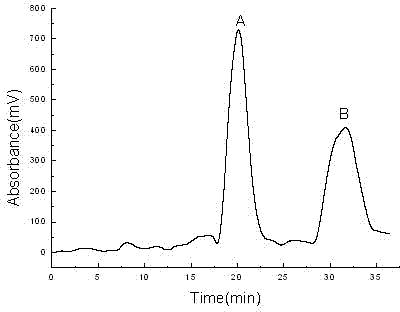

[0026] The Fructus Cnidii extract was dissolved in methanol, filtered (the filter membrane used was 0.45 μm filter membrane), and separated by supercritical fluid chromatography. The chromatographic column was a C18 chromatographic column, and the chromatographic column temperature was 40°C. The mobile phase is supercritical carbon dioxide, the flow rate is 3 times column volume / min, and the pressure is 15 MPa. The improver is methanol, and its proportion is 0.1%. The sep...

Embodiment 2

[0029] Weigh 500 grams of Fructus Cnidii, pulverize it with a pulverizer, put it in a glass container, add 3000ml of absolute ethanol to extract by cold soaking for 24 hours, extract 3 times, filter the extract, concentrate under reduced pressure to obtain an extract, and disperse the extract in In 1000ml water, extract 3 times with 1000ml petroleum ether. The combined petroleum ether extracts were distilled under reduced pressure to recover the petroleum ether to obtain Cnidium Fructus Cnidii Extract.

[0030] Fructus Cnidii extract is dissolved with methanol, after filtration, carry out supercritical fluid chromatography separation, and chromatographic column is C18 chromatographic column, and chromatographic column temperature is 45 ℃. The mobile phase is supercritical carbon dioxide, the flow rate is 5 times column volume / min, and the pressure is 12 MPa. The improver is methanol, and its ratio is 0.05%. The separation process is detected by an ultraviolet detector with a...

Embodiment 3

[0032] Weigh 500 grams of Fructus Cnidii, pulverize it with a pulverizer, put it in a glass container, add 1500ml of absolute ethanol to extract by cold soaking for 16 hours, extract 3 times, filter the extract, concentrate under reduced pressure to obtain an extract, and disperse the extract in 800ml of water, extracted 3 times with 800ml of petroleum ether. The petroleum ether extracts were combined, and the petroleum ether was recovered by distillation under reduced pressure to obtain Cnidium Fructus Cnidii Extract.

[0033] Fructus Cnidii extract is dissolved with methanol, after filtration, carry out supercritical fluid chromatography separation, and chromatographic column is C18 chromatographic column, and chromatographic column temperature is 40 ℃. The mobile phase is supercritical carbon dioxide, the flow rate is 4 times column volume / min, and the pressure is 13 MPa. The improver is methanol, and its ratio is 0.08%. The separation process is detected by an ultraviole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com