Method for dissolving poison solidified chromium slag

A technology for chromium slag and blast furnace slag is applied in the field of chromium slag detoxification and integrated detoxification and solidification of chromium slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

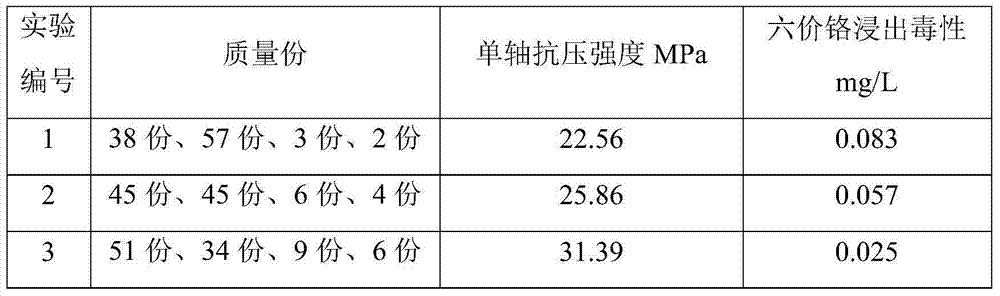

[0020] Different mass parts of embodiment 1 influence on solidification

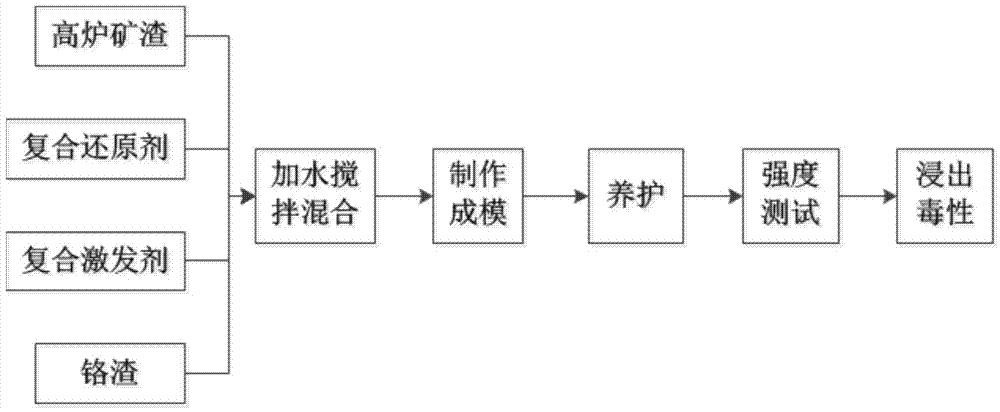

[0021] Dry and refine the chromium slag and blast furnace slag. After refinement, the particle size of the chromium slag and blast furnace slag is 200 mesh. Sodium hydroxide and water glass are mixed with a mass ratio of 1:1.5 to make a composite activator. Sodium sulfide and sulfurous acid Iron is mixed at a mass ratio of 1:1 to make a composite reducing agent. In terms of parts by mass (38 parts, 57 parts, 3 parts, 2 parts), (45 parts, 45 parts, 6 parts, 4 parts), (51 parts, 34 parts, 9 parts, 6 parts) respectively take the above refinement The final chromium slag, blast furnace slag, composite activator, and composite reducing agent are mixed, and then water is added at a liquid-solid mass ratio of 0.25:1 and stirred evenly, and then sequentially molded, solidified, and demoulded, and heated at a temperature of 25°C and a relative humidity of 90°C. Under the condition of more than %, carry out mainte...

Embodiment 2

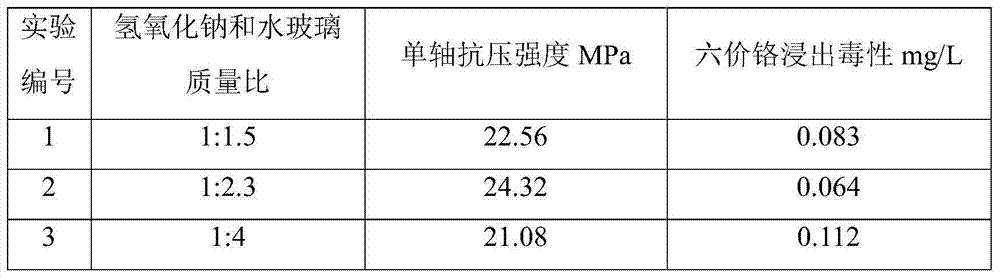

[0025] The impact of the different mass ratios of sodium hydroxide and water glass on the curing effect in the composite activator of embodiment 2

[0026] Dry and refine the chromium slag and blast furnace slag. After refining, the particle size of the chromium slag and blast furnace slag is 200 mesh. Mix sodium hydroxide and water glass at a mass ratio of 1:1.5, 1:2.3, and 1:4 respectively to make a composite As an activator, sodium sulfide and ferrous sulfate are mixed at a mass ratio of 1:1 to make a composite reducing agent. Take 38 parts of refined chromium slag, 57 parts of blast furnace slag, 3 parts of composite activator, and 2 parts of composite reductant, mix them, then add water at a liquid-solid mass ratio of 0.25:1 and stir evenly, then pour into the mold, solidify, Demoulding and curing for 28 days at a temperature of 25°C and a relative humidity of 90% or more to obtain solidified bodies of detoxified and solidified chromium slag. The preparation steps are as ...

Embodiment 3

[0030] The influence of embodiment 3 different liquid-solid ratios on solidification

[0031] Dry and refine the chromium slag and blast furnace slag. After refining, the particle size of the chromium slag and blast furnace slag is 200 mesh. Mix sodium hydroxide and water glass at a mass ratio of 1:2.3 to make a composite activator, and mix sodium sulfide and sulfuric acid Ferrous iron is mixed at a mass ratio of 1:1 to make a composite reducing agent. Take 38 parts of refined chromium slag, 57 parts of blast furnace slag, 3 parts of composite activator, and 2 parts of composite reductant, mix them, then add water at a liquid-solid mass ratio of 0.23:1, 0.25:1, 0.27:1 and stir evenly , and then sequentially molded, solidified, demoulded and maintained at a temperature of 25°C and a relative humidity of 90% or more for 28 days to obtain cured bodies of detoxified and cured chromium slag. The preparation steps are as follows: figure 1 . According to GB / T17671-1999 "Cement mort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com