Deviation-balancing-based lifting synchronization control method and apparatus of tundish car

A tundish truck and synchronous control technology, which is applied to fluid pressure actuators, servo motors, servo meter circuits, etc., can solve the problems of low control accuracy, unfavorable stability and dynamic performance of tundish trucks, and high equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

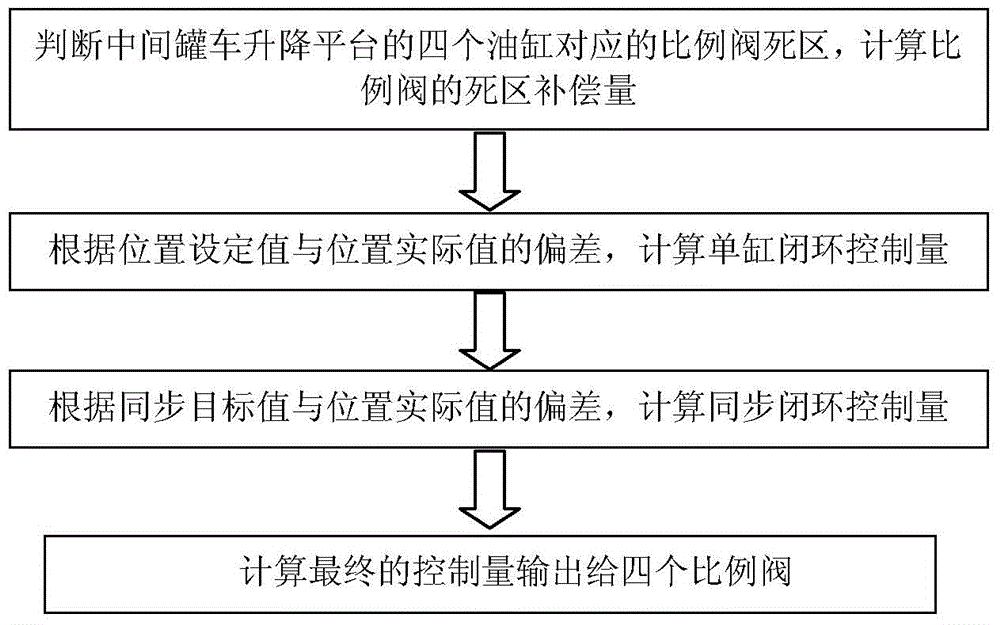

[0060] figure 1 It is a schematic flow chart of the method of the present invention, as shown in the figure, the method of the present invention specifically includes:

[0061] Step 1) Determine the dead zone of the proportional valve corresponding to the four oil cylinders, calculate the dead zone compensation amount of the proportional valve and output it.

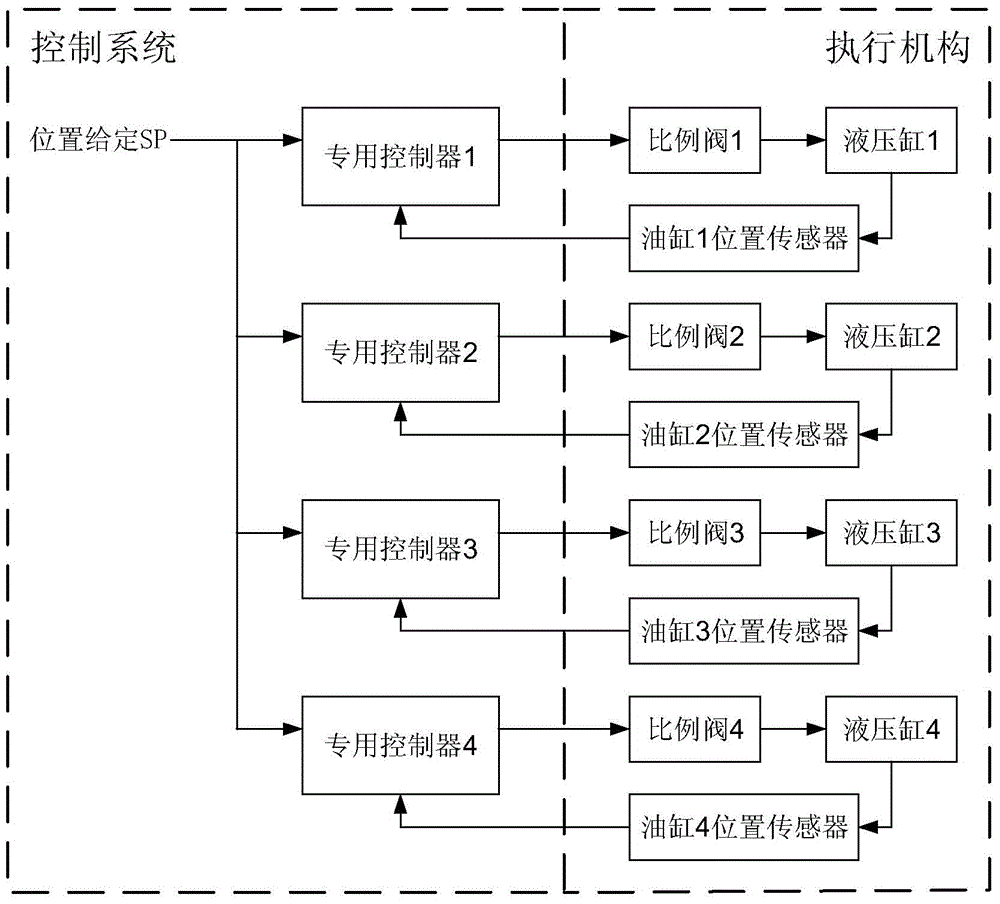

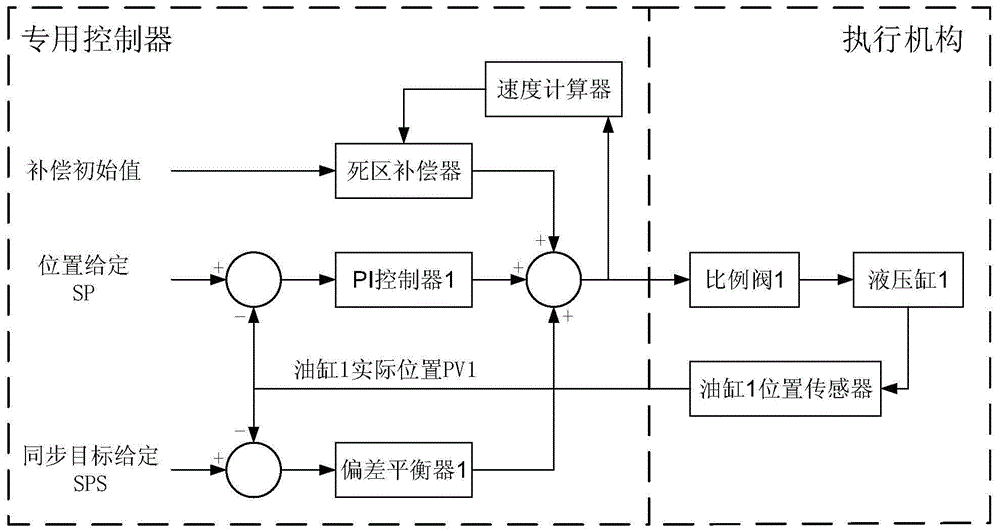

[0062] figure 2 It is a structural diagram of the method control system of the present invention, image 3 It is a schematic diagram of the internal algorithm of the method control system of the present invention. This step is used to eliminate the dead zone of the proportional valve, so that the final control value can cross this range, and try to keep the linear relationship between the flow rate of the proportional valve and the moving speed of the piston rod of the oil cylinder.

[0063] When the tundish truck platform rises, assign the initial value 0 to the dead zone compensation amount CV1(1) at the first mome...

Embodiment 2

[0086] Figure 4It is a hardware structure diagram of the device described in the present invention, which only shows a hardware structure diagram of a dedicated controller for a hydraulic cylinder, and the hardware structure of the remaining three hydraulic cylinder controllers is the same as that of the hydraulic cylinder, and only shows the same as that of this hydraulic cylinder for convenience of description. For the parts related to the embodiment of the invention, this embodiment provides a synchronous control device for lifting and lowering tundish trucks based on deviation balance. The device is a dedicated controller and includes the following units:

[0087] The dead zone compensation unit is used to judge the dead zone of the proportional valve corresponding to the four oil cylinders, and calculate the dead zone compensation amount of the proportional valve;

[0088] The single-cylinder deviation control unit calculates the single-cylinder closed-loop control amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com