Method for directly generating black corrosion-resistant micro-arc oxidation film layer on steel surface

A technology of micro-arc oxidation on the surface of steel, which is applied to the new process of preparing ceramic coatings on the surface of steel materials. The field of black wear-resistant and corrosion-resistant micro-arc oxidation film is directly generated on the surface of steel, which can solve the problem of easy rust and wear, and long development cycle , poor effect and other problems, to achieve the effect of stable and reliable process, expanded application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. The surface of Q235 carbon steel products is mechanically polished, and then degreased and decontaminated.

[0027] 2. Configure the electrolyte as follows: sodium aluminate 6-20g / l, sodium dihydrogen phosphate 2-5 g / l, sodium silicate 3-20 g / l, sodium vanadate 6-10 g / l, sodium sulfate 0.5-2g / l.

[0028] 3. Put Q235 carbon steel in the solution as an anode for micro-arc oxidation treatment, voltage 400-600v, current density 10-20A / dm 2 , process for 15-30 minutes.

[0029] 4. The product with the oxide film formed on the surface is washed and dried.

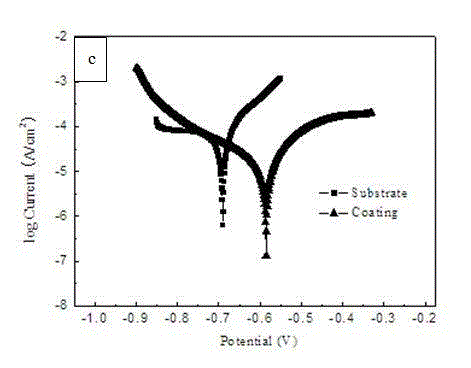

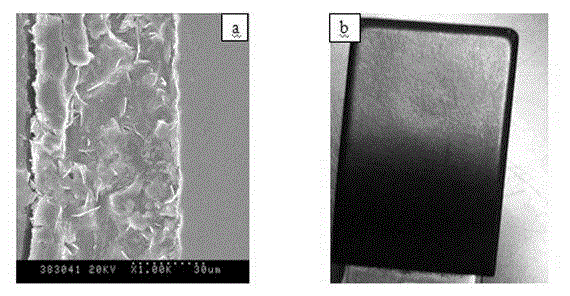

[0030] Characterization and testing of steel specimens with coatings such as figure 1 As shown in Figure 2, the cross-sectional thickness of the micro-arc oxidation film is about 50 microns, and the surface is black; the corrosion resistance of the film layer and the substrate is measured and compared with the Tafel polarization curve, and the corrosion current of the film layer is 100 times lower than that of t...

Embodiment 2

[0033] 1. Mechanically polish the surface of 30C rMnSi alloy steel products, and then carry out degreasing and decontamination cleaning.

[0034] 2. Configure the following electrolyte: sodium aluminate 8-20g / l, sodium dihydrogen phosphate 1-3g / l, sodium silicate 28-60 g / l, molybdic acid

[0035] Sodium 2-8 g / l.

[0036] 3. Use 30CrMnSi alloy steel products as anode for micro-arc oxidation treatment, voltage 400-600v, current density

[0037] 10-20A / dm 2 , process for 15-30 minutes.

[0038] 4. Clean and dry the products with oxide film formed on the surface.

[0039] 5. Characterize and test the steel sample with the film layer. The cross-sectional thickness of the micro-arc oxidation film layer is about 45 microns, and the surface is black, which is similar to figure 1 Similar; use Tafel polarization curve to measure and compare the corrosion resistance of the film layer and the substrate, the corrosion current density of the film layer is 8.162×10 -7 A / cm 2 Ratio mat...

Embodiment 3

[0041] 1. Mechanically polish the surface of T10 carbon non-alloy steel, and then carry out degreasing and decontamination cleaning.

[0042] 2. Configure the following electrolyte: sodium aluminate 15-30g / l, sodium dihydrogen phosphate 5-10 g / l, sodium silicate 56-96g / l, sulfuric acid

[0043] Sodium 0.5-1 g / l, sodium molybdate 2-8 g / l, sodium pyrophosphate 4-8 g / l.

[0044] 3. Use T10 carbon non-alloy steel as the anode for micro-arc oxidation treatment, voltage 400-650v, current density

[0045] 10-20A / dm 2 , process for 15-30 minutes.

[0046] 4. Clean and dry the steel with oxide film on the surface.

[0047] Characterization and testing were carried out on steel samples with a film layer. The thickness of the micro-arc oxidation film section was about 40 microns, and the surface was black, which was similar to that of figure 1 Similar; use Tafel polarization curve to measure and compare the corrosion resistance of the film layer and the substrate, the corrosion poten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com