Device and method used for realizing powdery iron mineral magnetization treatment and generating steam

A technology for steam production and magnetization, which is applied in the steam generation method using heat carrier, treatment of discharged materials, waste heat treatment, etc. It can solve the problems of waste of waste heat resources, many operating equipment, and large heat dissipation, and achieve resource utilization. High, saving construction investment, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

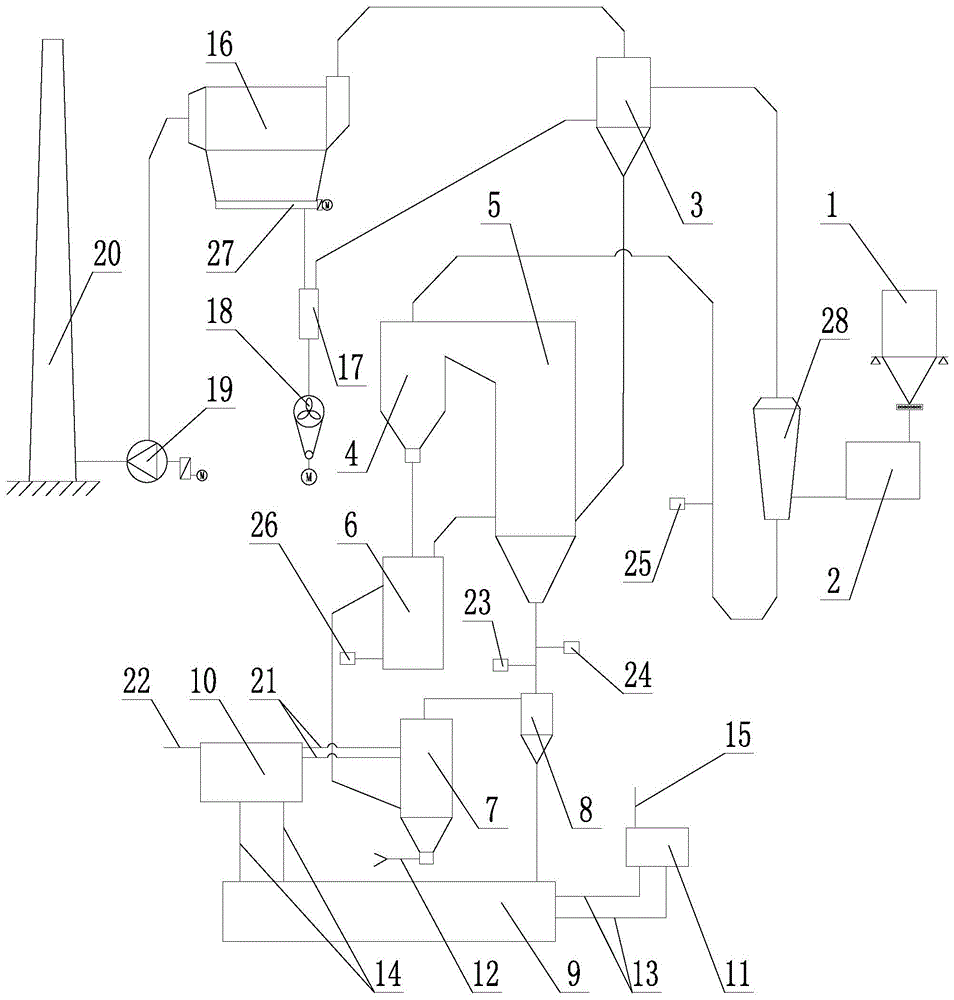

[0035] Such as figure 1 As shown, a device for magnetically treating powdery iron minerals and producing steam includes a feeding system, a roasting system, a magnetization separation system, a cyclone dust removal system and a steam production system; the feeding system includes a feeding bin 1, a metering Feeder 2 and drier 28; Described roasting system comprises cyclone preheater 3, suspension furnace 5, main combustion station 24, auxiliary combustion station 23 and dry combustion station 25; Described magnetization separation system comprises cyclone separator 4, Reactor 6, cyclone cooler 8 and gas supply station 26; the cyclone dust removal system includes dust collector 16, induced draft fan 19 and chimney 20; the steam production system includes rapid cooler 7, deaerator 11, waste heat boiler 9 and steam drum 10;

[0036]The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com