Monodisperse spindle-shaped nanosheets and preparation method thereof

A nanosheet and monodisperse technology, applied in the nanometer field, can solve the problems of poor dispersibility and uniformity, low product purity, and difficult shape control, and achieves good monodispersity and uniformity, and cheap and easy-to-obtain raw materials. , the preparation process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

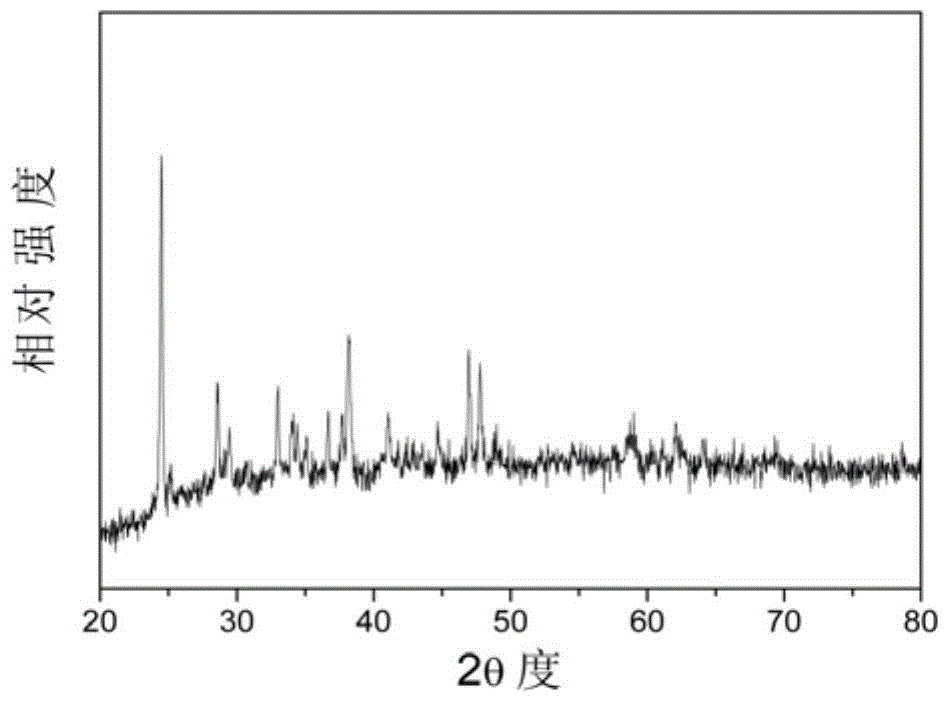

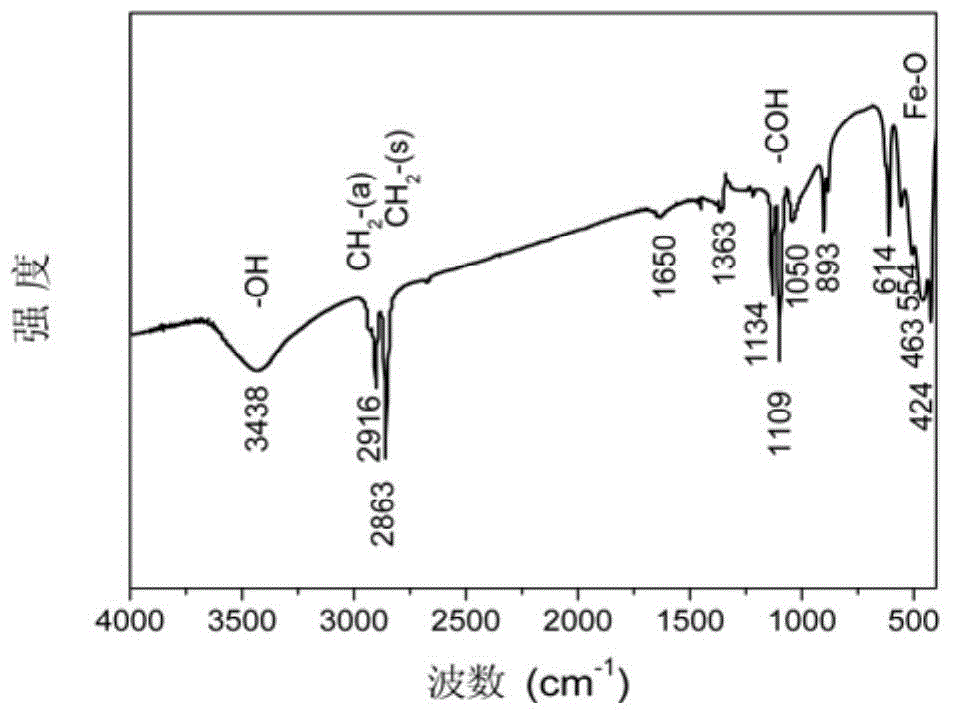

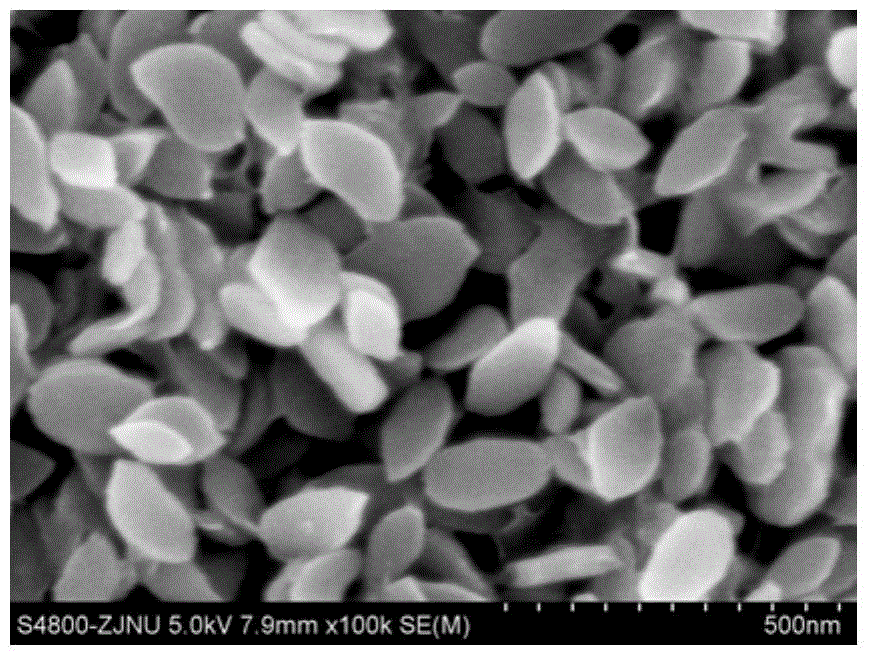

[0039] 5mmol FeCl 3 ·6H 2 O. Add 40 mL of ethylene glycol and 0.5 g of polyethylene glycol (PEG) 2000 to the Teflon liner and stir magnetically for 30 min. Add 10mmol of ethylenediamine (the ratio of alkali to metal salt substance is 2) into the inner liner, mix and stir for 2.0 hours. Finally, put the inner liner in a stainless steel kettle and react at 200°C for 12 hours, and then wash it by centrifugation after cooling (centrifuge and wash three times with water and ethanol respectively, the centrifugation rate is 5000 rpm, and the centrifugation time is 3 minutes each time). Dry at 60°C for 6h to obtain the desired monodisperse nanosheets. The resulting product is bright yellow, and the phase of the product, infrared spectrum, morphology observed under the scanning electron microscope and transmission electron microscope, and the selected area electron diffraction spectrum are as follows: Figure 1-4 shown. According to the literature [Adv.Funt.Mater.2010,20,1680; J.Am...

Embodiment 2

[0042] The steps are the same as in Example 1, but the reaction temperature is 150°C. The resulting product is bright yellow, and the morphology observed under the scanning electron microscope is as follows: Figure 6 As shown, it can be seen that the product is a glycolate polycrystalline fusiform nanosheet of iron, with a major axis length of 34-59 nm and an average length of 48 nm; the ratio of the major axis to the minor axis is 1.52-2.72, with an average of 2.02.

Embodiment 3

[0044] The steps are the same as in Example 1, but the reaction temperature is 180°C. The resulting product is bright yellow, and the morphology observed under the scanning electron microscope is as follows: Figure 7 As shown, it can be seen that the product is a glycolate polycrystalline shuttle-shaped nanosheet of iron, with a major axis length of 132-178 nm and an average length of 153 nm; the ratio of its major axis to minor axis is 1.86-2.17, an average of 2.05, and a thickness of 33 nm. ~37nm, with an average thickness of 34nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com