High-temperature-resistant high-bonding-strength low infrared emissivity composite coating, metal alloy material with coating and preparation method of metal alloy material

A low-infrared emission and composite coating technology, which is applied in the coating, overlay coating, metal material coating process, etc., can solve the problems of coating performance deterioration, high equipment requirements, high cost, etc., and achieve high temperature stability Effects of improved emissivity, excellent bonding strength, and increased operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

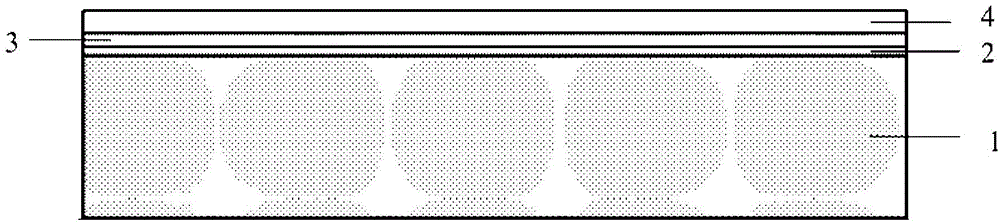

[0044] Such as figure 1 Shown, a kind of metal alloy material that is coated with the low infrared emissivity composite coating of high temperature resistance, high bonding strength of the present invention, comprises metal alloy substrate 1 (metal alloy substrate adopts aerospace K424 alloy) and is coated on metal A low-infrared emissivity composite coating on the alloy substrate 1, the low-infrared emissivity composite coating is a multi-layer superposition structure, and the multi-layer superposition structure includes a metal bonding layer 2, a ceramic transition layer 3 and a low emissivity function from the inside to the outside. Layer 4, wherein the metal bonding layer 2 is a NiCrAlY plasma sprayed layer, and the ceramic transition layer 3 is ZrO 2 Plasma sprayed layer, low emissivity functional layer 4 is ZrO containing AgPd alloy 2 -Al 2 o 3 -SiO 2 Department of glass coating. The thickness of the metal bonding layer 2 is controlled to be 100 μm, the thickness of...

Embodiment 2

[0058] Such as figure 1 Shown, a kind of metal alloy material that is coated with high temperature resistance of the present invention, the low infrared emissivity composite coating of high binding strength comprises metal alloy substrate 1 (metal alloy substrate adopts 1Cr17 stainless steel substrate) and is coated on metal alloy A low-infrared-emissivity composite coating on the substrate 1, the low-infrared-emissivity composite coating is a multi-layer superposition structure, and the multi-layer superposition structure sequentially includes a metal bonding layer 2, a ceramic transition layer 3 and a low-emissivity functional layer from the inside to the outside 4. Among them, the metal bonding layer 2 is NiCrAlY plasma sprayed layer, and the ceramic transition layer 3 is ZrO 2 Plasma sprayed layer, low emissivity functional layer 4 is ZrO containing AgPd alloy 2 -Al 2 o 3 -SiO 2 Department of glass coating. The thickness of the metal bonding layer 2 is controlled to b...

Embodiment 3

[0072] Such as figure 1 Shown, a kind of metal alloy material that is coated with the low infrared emissivity composite coating of high temperature resistance, high bonding strength of the present invention, comprises metal alloy substrate 1 (metal alloy substrate adopts 304 alloy steel) and is coated on metal alloy substrate A low-infrared-emissivity composite coating on 1, the low-infrared-emissivity composite coating is a multi-layer superposition structure, and the multi-layer superposition structure sequentially includes a metal bonding layer 2, a ceramic transition layer 3 and a low-emissivity functional layer 4 from the inside to the outside , where the metal bonding layer 2 is NiCrAlY plasma sprayed coating, and the ceramic transition layer 3 is ZrO 2 Plasma sprayed layer, low emissivity functional layer 4 is ZrO containing AgPd alloy 2 -Al 2 o 3 -SiO 2 Department of glass coating. The thickness of the metal bonding layer 2 is controlled to be 150 μm, the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com