Turbine-generator shaft system torsional vibration protection method and device

A technology for torsional vibration of generator sets and shafting, applied to emergency protection circuit devices, emergency protection devices for automatic disconnection, circuit devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below according to the drawings and embodiments.

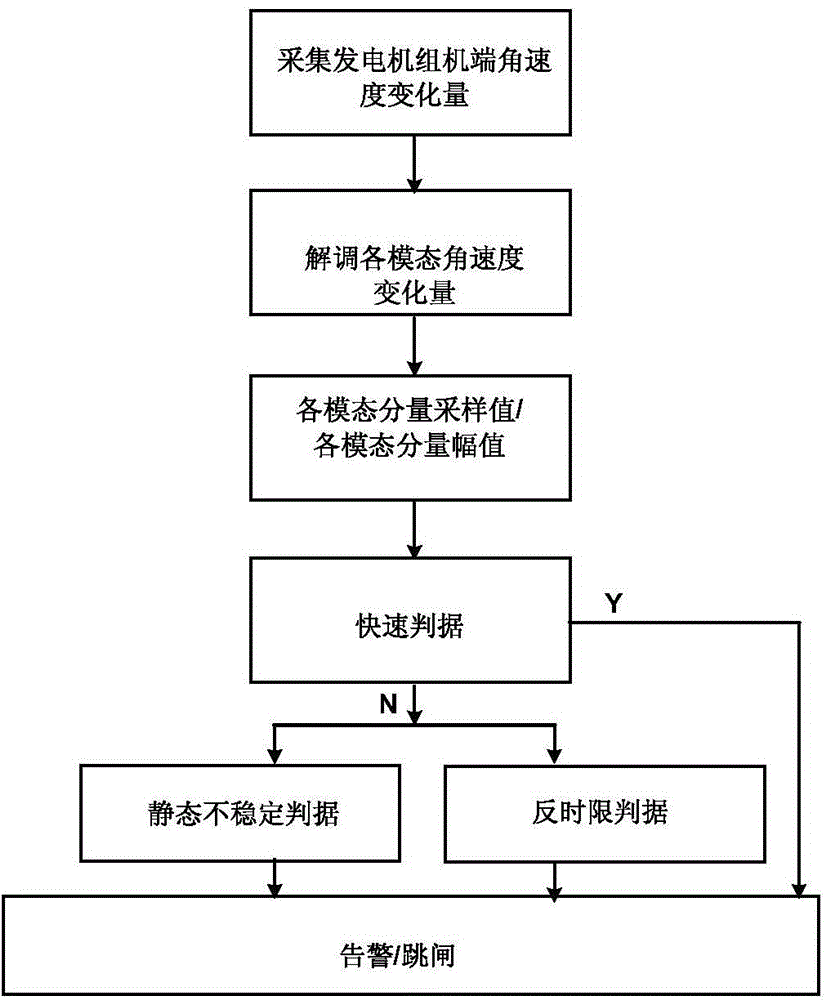

[0055] The present invention proposes a method for protecting the shafting torsional vibration of a generator set, the method includes the following steps, such as figure 1 Shown:

[0056] Collect the variation of angular velocity at the shaft end of the generating set; apply the non-contact sensor to sense the pulse signal generated by the gear rotating with the shaft. When each tooth passes the sensor, a pulse signal is generated. When the rotor rotates at a constant speed, the position of the pulse train reflects the arrangement position of each tooth on the circumference of the gear. The output of the sensor is a uniform pulse wave. When the rotor vibrates, the position of each pulse changes, and the vibration makes the phase shift of the pulse signal, and the output is a pulse wave with alternating density and density. By extracting this phase shift, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com