Twisting-resistant and stretching-resistant mobile type cable and preparation method thereof

A mobile and cable technology, which is applied in the field of power cables, can solve problems such as cable core twisting, cable failure, and short service life, and achieve the effects of ensuring deformation margin, prolonging service life, and protecting safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

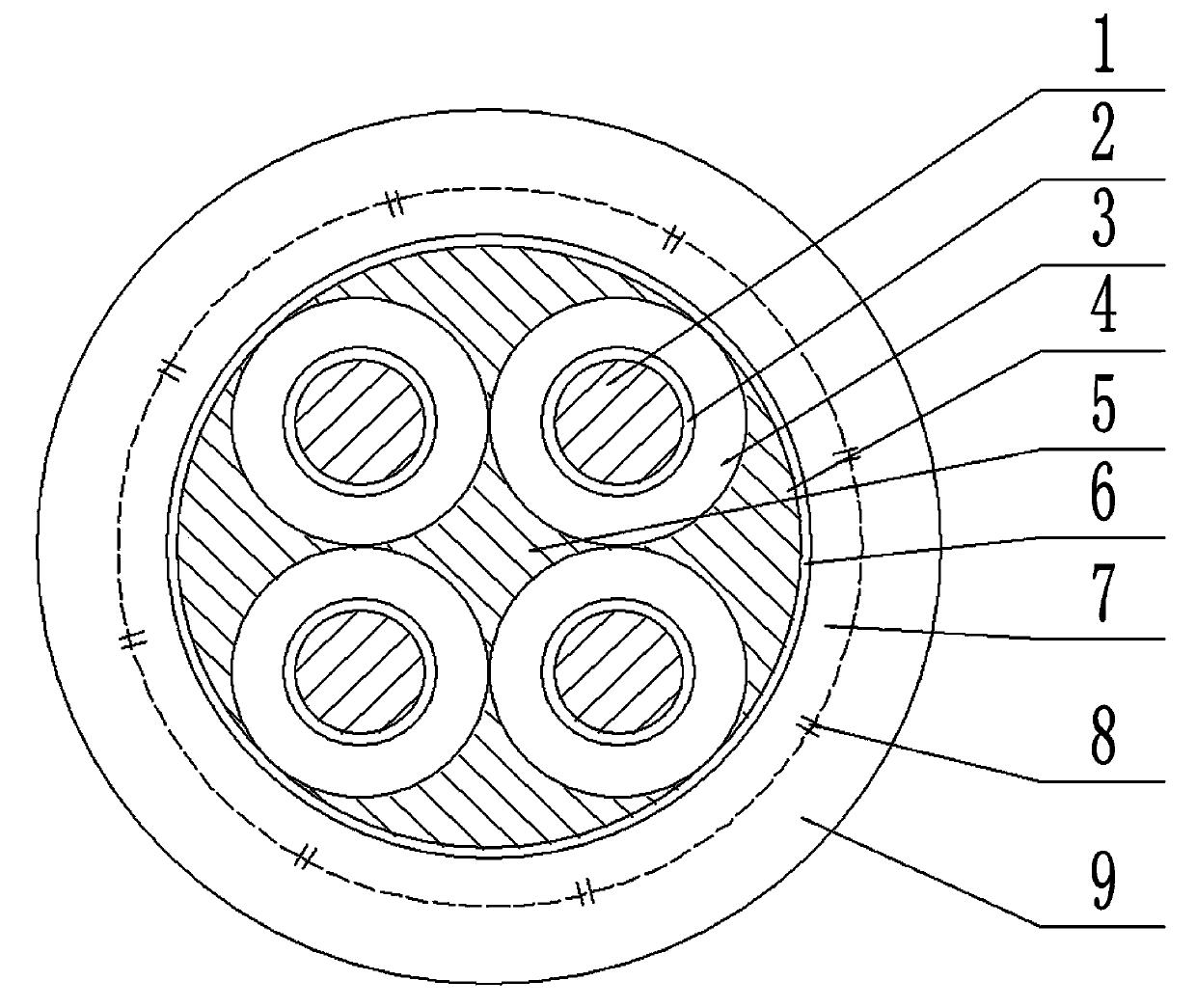

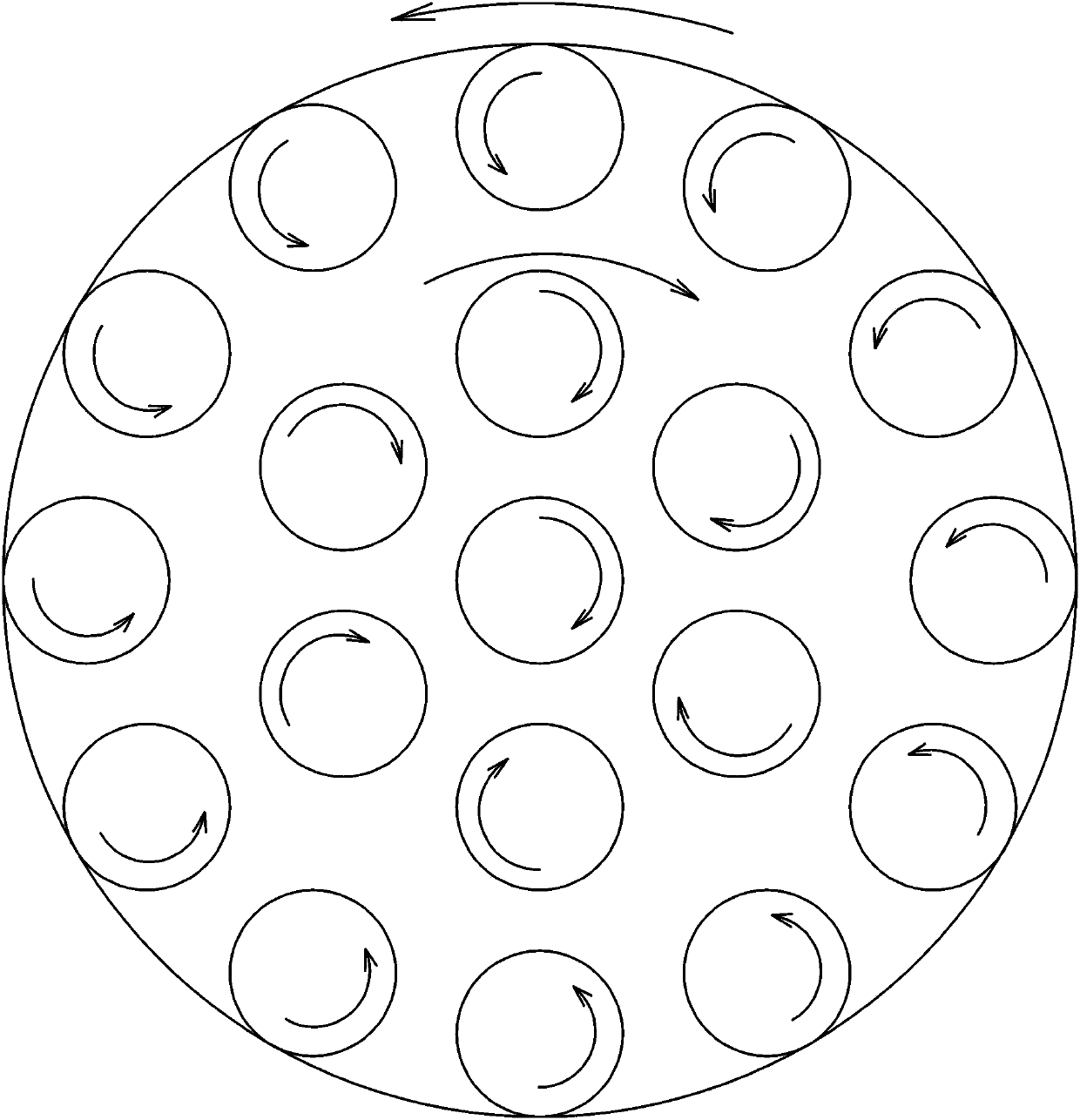

[0034] Such as figure 1 , 2 Among them, a torsion-resistant and tensile-resistant mobile cable includes a plurality of cable cores containing conductors 1. Specifically, the conductor 1 is surrounded by a conductor isolation zone 2, and the conductor isolation zone 2 is an insulating layer 3. There is an inter-core filler 5 between the cores, an outer core filler 4 is arranged outside the cable core, a cable core isolation belt 6 is arranged outside the outer core filler 4, and a sheath layer is arranged outside the cable core isolation belt 6, and the conductor 1 is composed of strands The wires are formed after being bundled and re-twisted. When the strands used in conductor 1 are re-twisted, the rotation direction of each layer of twisted wires is the same, that is, the bundled direction of each layer of strands is the same as the rotation direction of the twisted wires, and the adjacent layer of strands The direction of re-twisting is opposite. With this structure, the m...

Embodiment 2

[0040] A method for preparing the cable described in Example 1, comprising the steps of:

[0041] 1. When the strands of conductor 1 are bundled, part of them is left-handed, and part of them is right-handed, and the diameter ratio of bundle joints is 16~18;

[0042] 2. When the strands are re-twisted, the directions of the twisted wires of each layer are the same, that is, the bundled direction of the strands is the same as the direction of the twisted strands, and the direction of the adjacent layers of twisted wires is opposite, and the twisted joint diameter is 9~11 , Outer layer 8~9;

[0043] 3. Overlap and wrap a layer of high-temperature polyester tape outside the conductor 1 in the opposite direction to the outer layer;

[0044] 4. Extrude the vulcanized insulating layer 3 to make the cable core, and coat the insulating layer 3 with superfine talcum powder;

[0045] 5. Set the inter-core filling 5 between the cable cores. There are no less than 2 strands of aramid ya...

Embodiment 3

[0055] This example is on the basis of Examples 1 and 2, further preferred examples, such as figure 1 , 2 shown in .

[0056] 1. Material

[0057] Conductor 1 is the sixth kind of soft copper conductor, conductor isolation tape 2 is high-temperature polyester tape, insulation layer 3, core outer filler 4 and inter-core filler 5 are XJ-30B rubber, cable core isolation belt 6 is reinforced non-woven fabric , the inner sheath 7 and the outer sheath 9 are chlorinated polyethylene, and the fiber bundle reinforcement layer 8 is aramid yarn.

[0058] 2. Conductor

[0059] The monofilament meets the requirements of TR type in GB / T3953-2009.

[0060] Conductor structure: 19 strands × 17 strands / single wire diameter 0.20mm.

[0061] The bundle direction of the strands is 12 strands to the left and 7 strands to the right, and the bundle pitch ratio is 16~18.

[0062] The stranding direction of the double-stranded conductor is left-handed on the outer layer and right-handed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com