Torsional Vibration Protection Method and Device for Turbine Generator Shaft System

A shafting torsional vibration and generator set technology, which is applied to emergency protection circuit devices, emergency protection devices with automatic disconnection, circuit devices, etc., can solve problems that do not involve protection schemes and criteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the present invention will be further described in detail based on the drawings and embodiments.

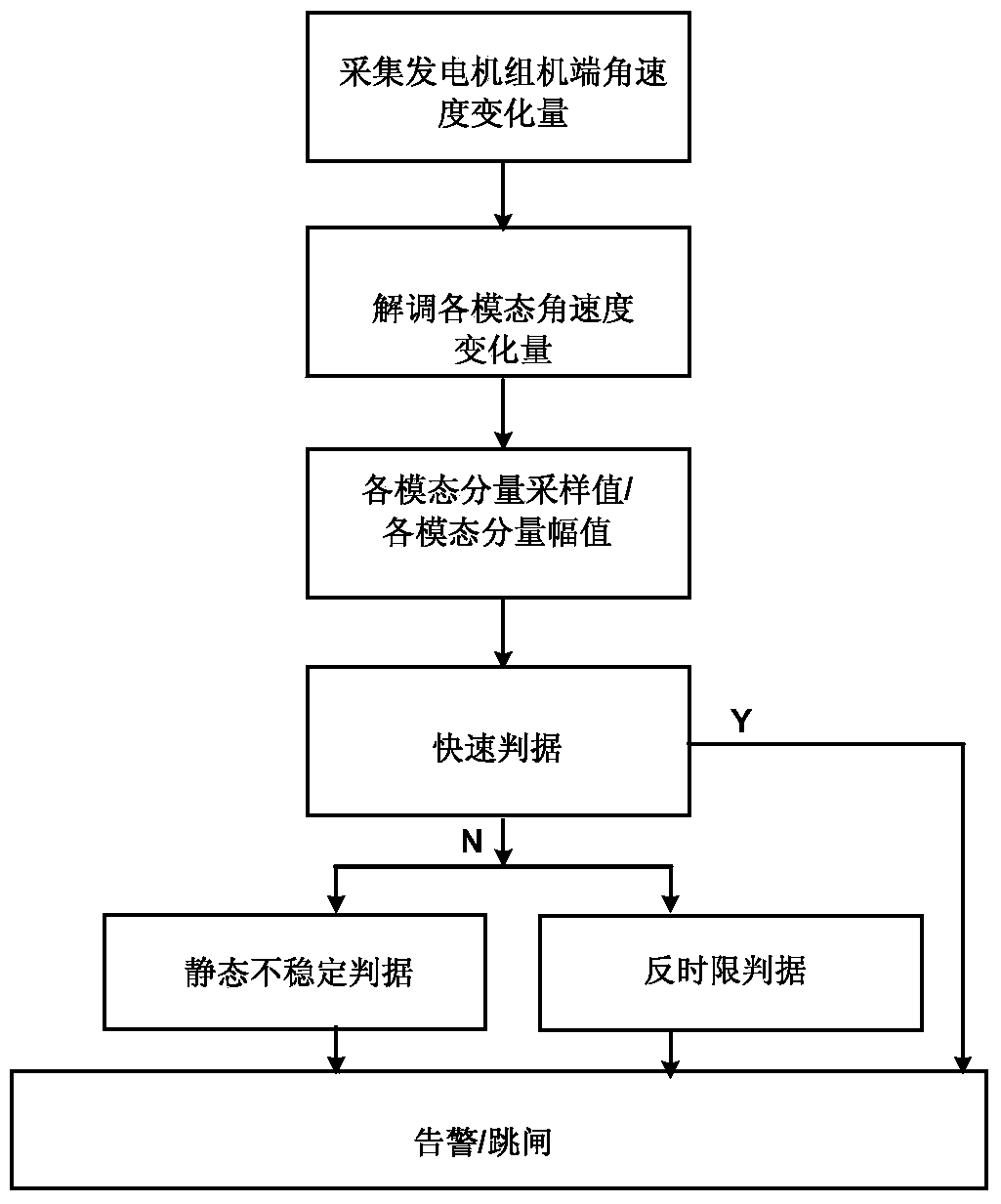

[0055] The present invention provides a method for protecting the shaft torsional vibration of a generator set. The method includes the following steps, such as figure 1 Shown:

[0056] Collect the angular velocity change of the shafting machine end of the generator set; apply the non-contact sensor to sense the pulse signal generated by the gear rotating with the shaft. When each tooth passes the sensor, a pulse signal is generated. When the rotor rotates at a constant speed, the pulse train position reflects the arrangement position of the teeth on the gear circumference. The output of the sensor is a uniform pulse wave. When the rotor vibrates, the position of each pulse changes, and the vibration causes the pulse signal to undergo a phase shift, and the output is a sparse and dense pulse wave. Extracting this phase displacement, we get a set of sampled value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com