A preparation method of silica@quantum dot composite nanoparticles

A technology of composite nanoparticles and silica, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve problems such as batch production of unfavorable products, large-scale synthesis, difficult and stable reaction conditions control, and large reaction energy consumption. , to facilitate centrifugal separation, simplify post-processing steps, and facilitate the separation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of mercapto-silica nanoparticles

[0036] Add ammonia water and water to absolute ethanol, add TEOS under stirring condition, the concentration of ammonia water in the final mixture is 2.6×10 -1 mol / L, the concentration of water is 4.1×10 -2 mol / L, the concentration of TEOS is 3.2×10 -2 mol / L, react at room temperature for 4 hours; then add MPS, the concentration of MPS in the mixture is 7.2×10 -6 mol / L, reacted at room temperature for 8 hours; the mixture was centrifuged, and the resulting precipitate was vacuum-dried to obtain mercapto-silica nanoparticles.

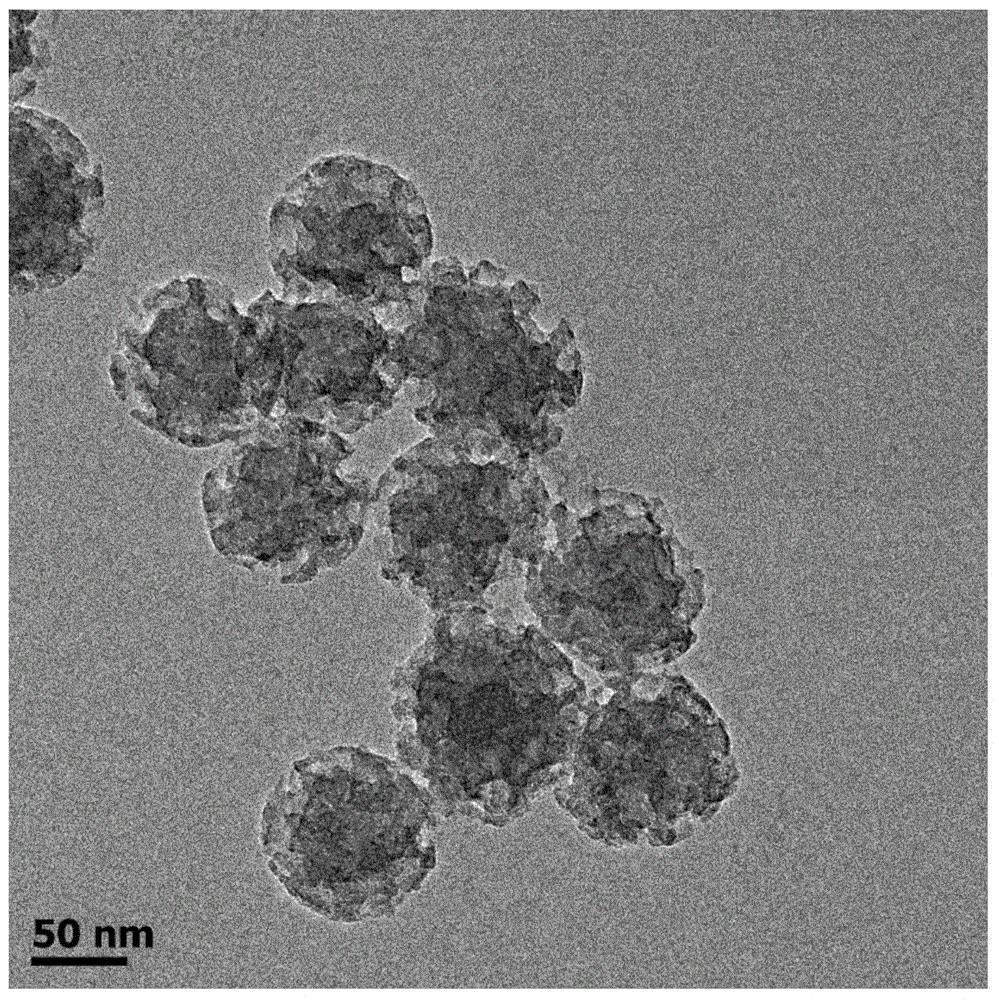

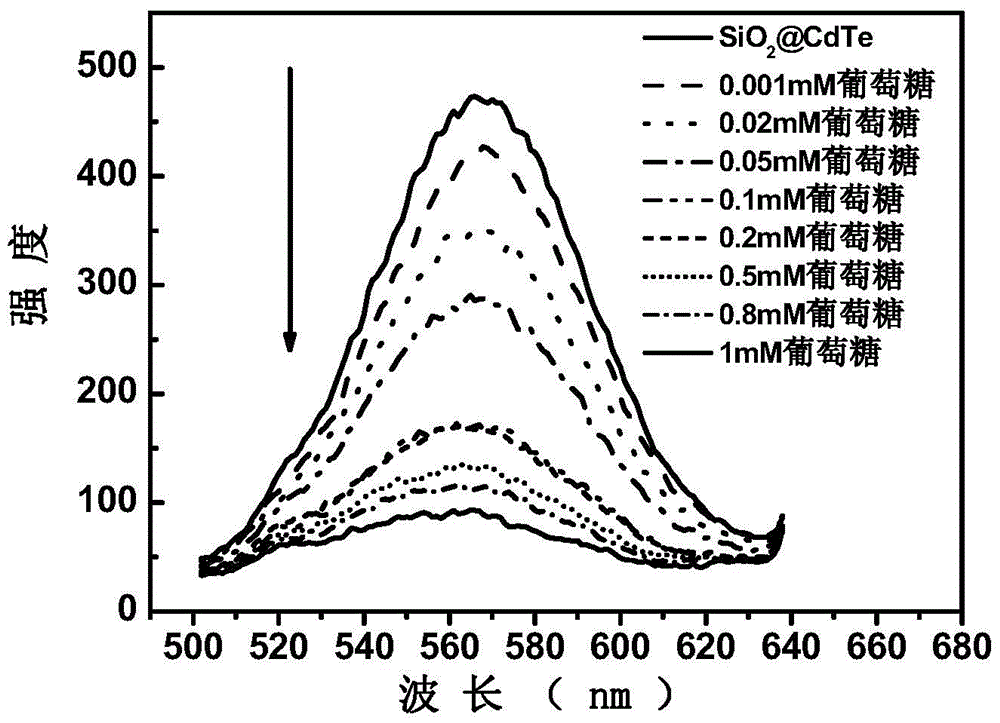

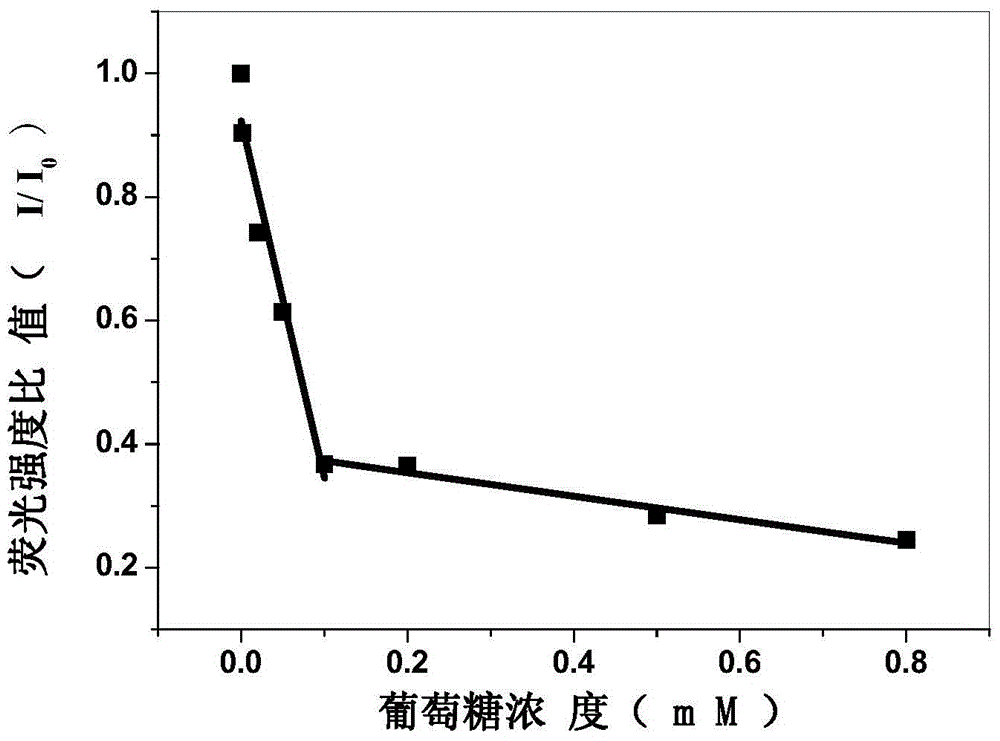

[0037] 2. Preparation of silica@cadmium telluride composite nanoparticles

[0038] Disperse the mercapto-silicon dioxide nanoparticles synthesized in step 1 in an aqueous solution, add cadmium chloride and mercaptopropionic acid, adjust the pH value of the solution to 9.5 with sodium hydroxide, and then add sodium telluride hydride to form a precursor mixed solution , where the concentration of...

Embodiment 2

[0050] 1. The preparation of mercapto-silicon dioxide nanoparticles is the same as in Example 1.

[0051] 2. Synthetic silica@lead sulfide composite nanoparticles

[0052] The mercapto-silicon dioxide nanoparticles synthesized in step 1 are dispersed in an aqueous solution, lead chloride and N-acetyl-L-cysteine are added, and the pH value of the solution is adjusted to 11 with potassium hydroxide, and then sodium sulfide is added, Prepare quantum dot precursor solution, wherein the concentration of mercapto-silica nanoparticles is 4.2×10 -3 mol / L, the concentration of lead chloride is 1.2×10 -5 mol / L, the concentration of sodium sulfide is 2.5×10 -6 mol / L, the concentration of N-acetyl-L-cysteine is 3.0×10 -5 mol / L. The precursor solution was poured into a hydrothermal kettle and reacted at 160°C for 1 hour; the mixture was centrifuged, and the resulting precipitate was vacuum-dried to obtain silica@lead sulfide composite nanoparticles.

[0053] The method can be used...

Embodiment 3

[0062] 1. Preparation of mercapto-silica nanoparticles

[0063] Add ammonia water and water to absolute ethanol, add TEOS under stirring condition, the concentration of ammonia water in the final mixture is 4.5mol / L, and the concentration of water is 3.6×10 -3 mol / L, the concentration of TEOS is 5.1×10 -1 mol / L, react at room temperature for 6 hours; then add MPS, the concentration of MPS in the mixed solution is 3.4×10 -5 mol / L, reacted at room temperature for 12 hours; the mixture was centrifuged, and the resulting precipitate was vacuum-dried to obtain mercapto-silica nanoparticles.

[0064] 2. Synthesis of silica@zinc sulfide composite nanoparticles

[0065] Disperse the thiolated silica nanoparticles synthesized in step 1 in an aqueous solution, add zinc acetate and mercaptoacetic acid, adjust the pH value of the solution to 8.6 with sodium hydroxide, then add sodium sulfide to form a quantum dot precursor solution, wherein The concentration of thiolated silica nanopar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com