Method of freezing, concentrating and treating saline wastewater

A technology of freezing and concentrating salty wastewater, which is applied in the direction of chilled water/sewage treatment, general water supply saving, etc., can solve the problem of high cost of wastewater treatment, and achieve the effects of large-scale production, strong adaptability, and reduced equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

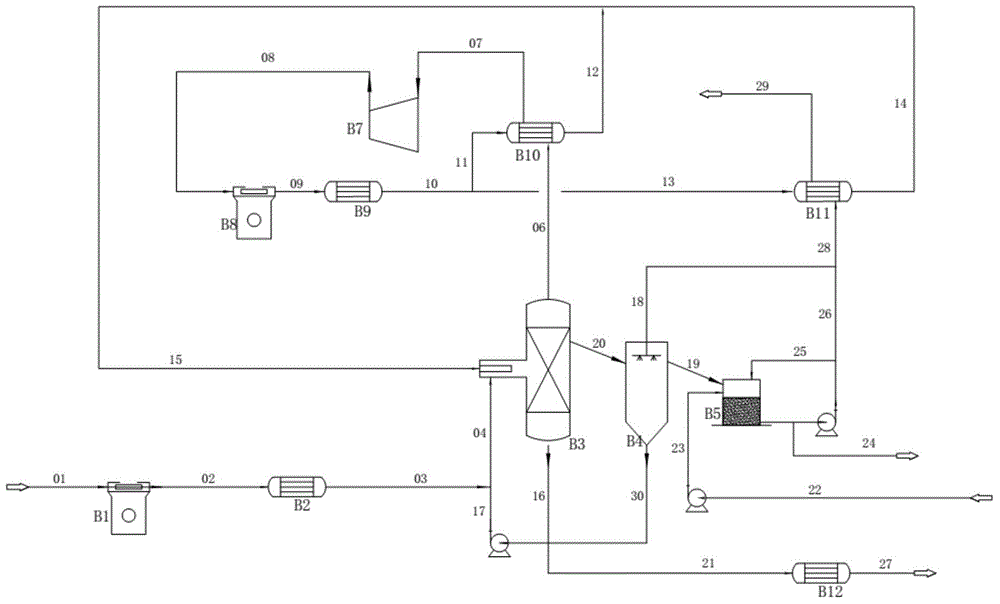

[0060] Embodiment 1, freezing and concentrating treatment of gasification furnace black water

[0061] like figure 1 As shown, the technological process of freezing and concentrating the black water of the gasification furnace in the present embodiment is as follows:

[0062] (1) Mixing of materials in the crystallizer

[0063] A. Raw water and concentrated brine: the black water raw water 01 from the gasifier of the upstream unit is first cooled to 45°C by the air cooler B1 to obtain raw water 02, and the raw water 02 is cooled to 40°C by the water cooler B2 to obtain raw water 03. The thicker saline waste water 16 (salt content is 4.5%, temperature is-1 ℃, pressure is 0.42MPa) from the bottom of crystallizer B3 and wash water and impurity 30 from the bottom of solid-liquid separator B4 are combined with the above-mentioned raw water 03 is mixed into 04 and sent to crystallizer B3.

[0064] B. Refrigerant: The gas-phase refrigerant 08 from the outlet of the compressor B7 i...

Embodiment 2

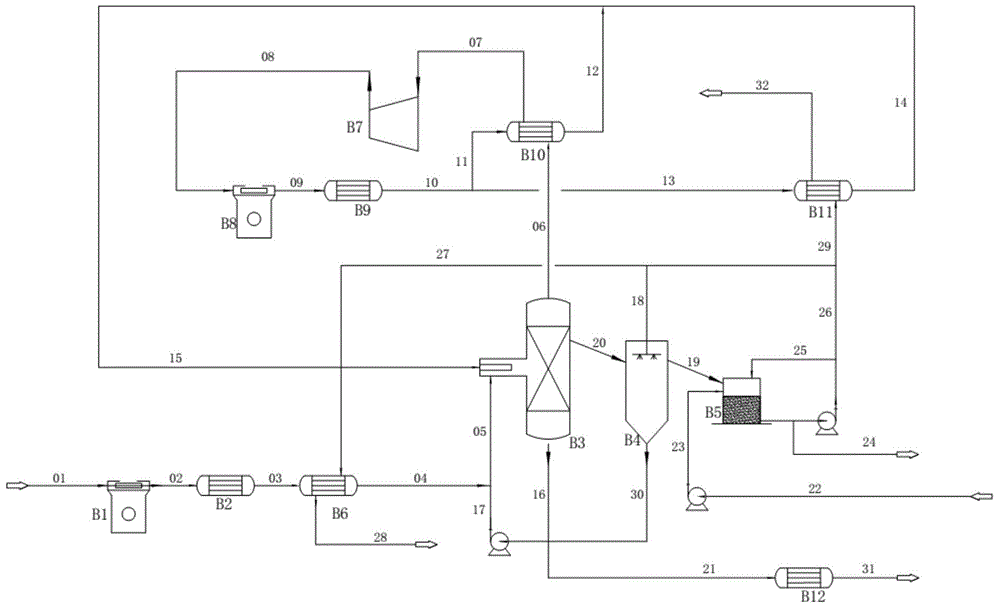

[0077] Embodiment 2, freezing and concentrating treatment of gasification furnace black water

[0078] like figure 2 As shown, the technological process of freezing and concentrating the black water of the gasification furnace in the present embodiment is as follows:

[0079] (1) Mixing of materials in the crystallizer

[0080] A. Raw water and concentrated brine: the black water raw water 01 from the upstream unit (with a salt content of 0.05% to 0.5%, a temperature of 75°C and a pressure of 0.5MPa) is cooled to 45°C to 50°C by air cooler B1 ℃ is raw water 02. The raw water 02 cooled by air cooling is the raw water 03 after being cooled to 40° C. by the water cooler B2. The raw water 03 and the chilled water 27 (at a temperature of 7° C.) from the deicing tank B5 are cooled by heat exchange in the heat exchanger B6. Raw water 04 after cooling and part low-temperature concentrated brine 16 from crystallizer B3 bottom (salt content is 4.5%, temperature is-1 ℃, pressure is ...

Embodiment 3

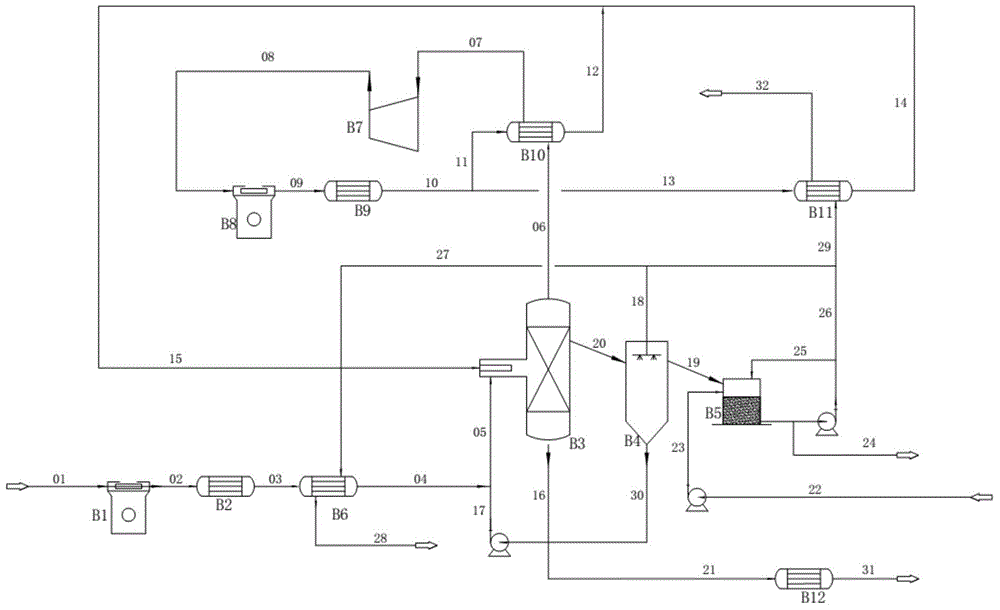

[0096] Embodiment 3, freezing and concentrating treatment of gasification furnace black water

[0097] like image 3 As shown, the technological process of freezing and concentrating the black water of the gasification furnace in the present embodiment is as follows:

[0098] (1) Mixing of materials in the crystallizer

[0099] A. Raw water and concentrated brine: Black water raw water 01 from the upstream unit (salt content: 0.05%, temperature: 75°C, pressure: 0.2MPa) is cooled by air cooler B1 to 45°C-50°C, that is, raw water 02. The raw water 02 cooled by air cooling is the raw water 03 after being cooled to 40° C. by the water cooler B2. The raw water 03 and the chilled water 27 (at a temperature of 7° C.) from the deicing tank B5 are cooled by heat exchange in the heat exchanger B6. Cooled raw water 04 and part of the low-temperature concentrated brine 16 from the bottom of the crystallizer B3 (salt content is 2%, temperature is -1 ° C, pressure is 0.12MPa) and from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com