A power battery thermal management system based on thermoelectric cooling

A heat management system and power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of poor matching of battery shape, failure to meet battery heat dissipation requirements, complex structure of liquid cooling system, etc., to achieve structural Compactness, extended life, and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below.

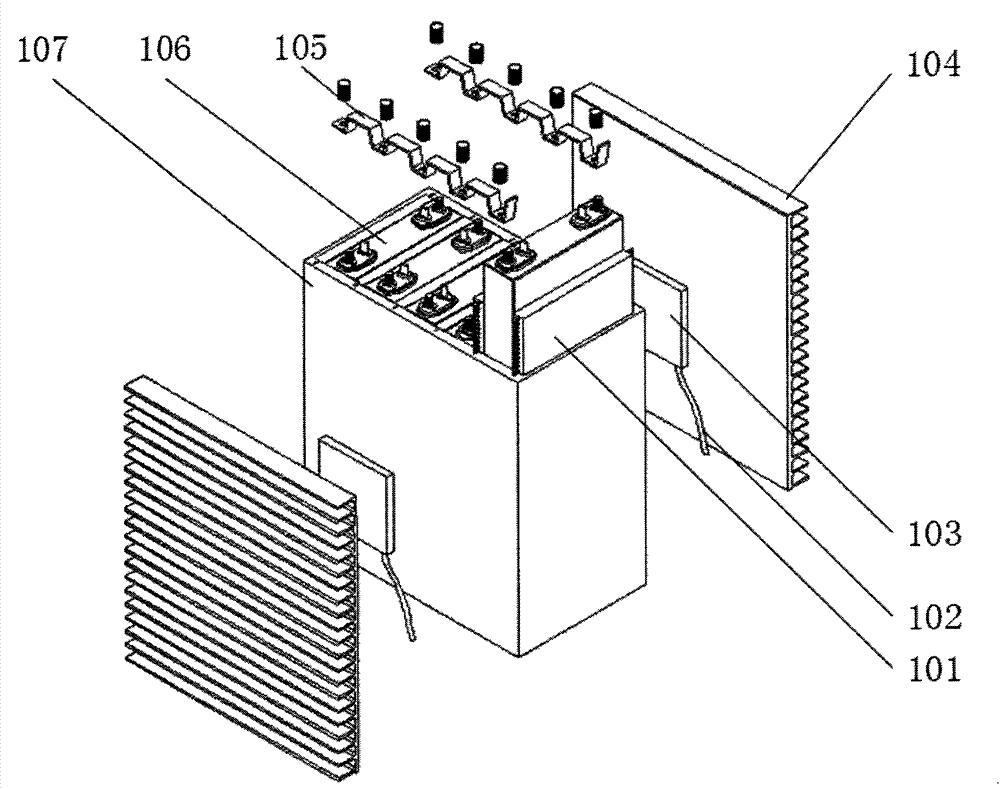

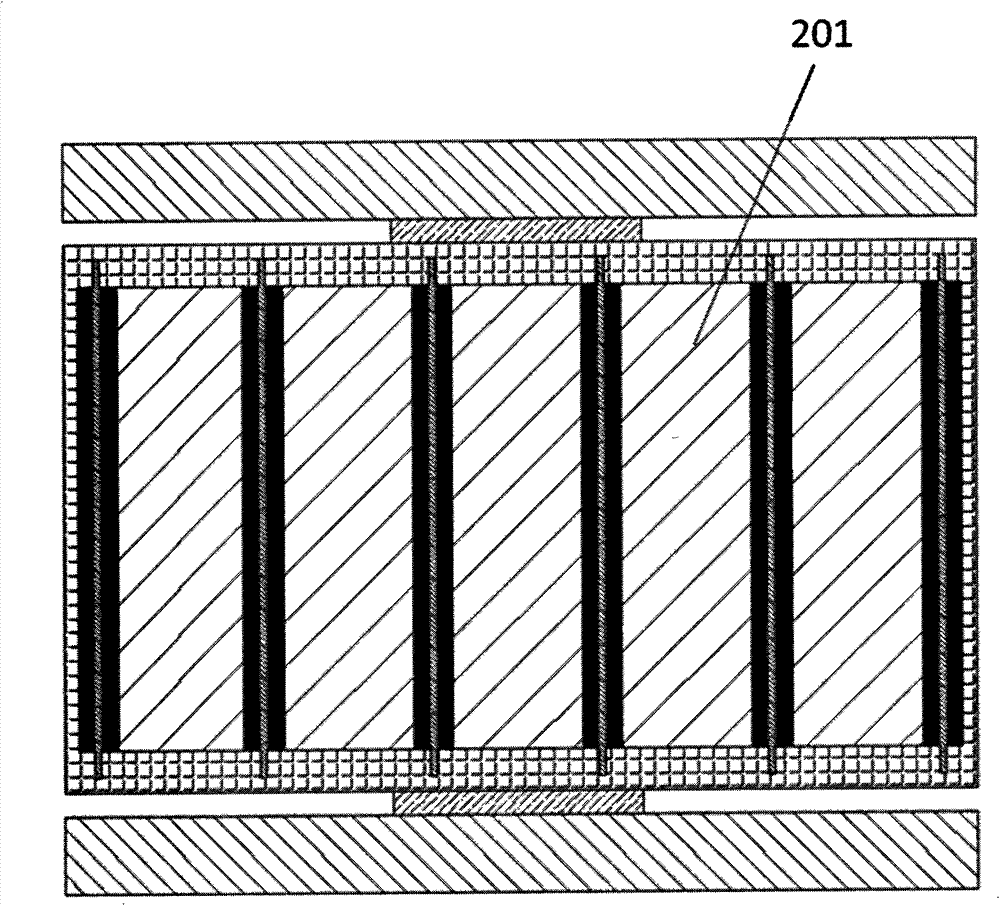

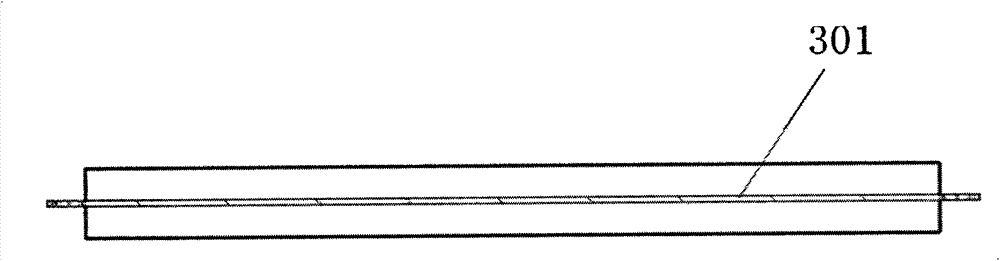

[0021] Such as Figure 1 to Figure 5 As shown, a power battery thermal management system based on thermoelectric cooling in the present invention uses a composite phase change material 101 and a thermoelectric semiconductor chip 103 as a medium, and the battery thermal management system includes a battery module 201 and a battery case for accommodating the battery module 201 107. The thermoelectric semiconductor chips 103 embedded in the two sides of the battery case 107, the fin radiator 104 located on the upper end of the thermoelectric semiconductor chip 103, the square unit battery 106 located inside the battery case 107, and the electric unit for the unit battery 106. The connected connecting piece 105, the composite phase change material 101 embedded between the square single cells 106, the skeleton metal mesh (stainless steel mesh, aluminum mesh or copper mesh, etc.) 301 inside the composite ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com