Sodium-rich P2-phase layered oxide material and preparation method and application thereof

An oxide and layered technology, applied in the field of materials, can solve the problems of sacrificing specific capacity and energy density, affecting the electrochemical performance of materials, and unstable storage for a long time, achieving high working voltage, low cost, and stable cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 of the present invention provides a sodium-rich P2 phase layered oxide material, whose general chemical formula is: Na 0.72+δ Ni a mn b m c o 2+σ ;

[0049] Wherein, Ni and Mn are transition metal elements, M is an element for doping and replacing the transition metal position, and the M is specifically Mg 2+ , Zn 2+ , Cu 2+ , Mn 2+ ,Co 2+ , Al 3+ , Mn 3+ , Fe 3+ ,Co 3+ , V 3+ , Cr 3+ , Ti 4+ , Zr 4+ , Si 4+ , Sn 4+ , Ru 4+ , Nb 4+ , Mo 4+ One or more of them; the valence state of M is m, and the m is specifically monovalent, divalent, trivalent, tetravalent, pentavalent or hexavalent;

[0050] The δ, a, b, c, σ are the mole percentages of the corresponding elements respectively; the relationship between the δ, a, b, c, σ and m satisfies (0.72+δ)+2a+4b+mc =2(2+σ), and satisfy a+b+c=1; among them, -0.05<δ≤0.08; 0

[0051] in Na 0.72+δ Ni a mn b m c o 2+σ In the structure, Ni, M, and Mn res...

Embodiment 2

[0055] This example provides a method for preparing a sodium-rich P2 phase layered oxide material, specifically a solid phase method, such as figure 2 shown, including:

[0056] Step 201, mixing sodium carbonate with a required stoichiometric amount of 102wt% to 105wt% of sodium and required stoichiometric amounts of manganese dioxide, nickel oxide, and M oxide in proportion to form a precursor;

[0057] Specifically, the M is specifically M is specifically Mg 2+ , Zn 2+ , Cu 2+ , Mn 2+ ,Co 2+ , Al 3+ , Mn 3+ , Fe 3+ ,Co 3+ , V 3+ , Cr 3+ , Ti 4+ , Zr 4+ , Si 4+ , Sn 4+ , Ru 4+ , Nb 4+ , Mo 4+ one or more of.

[0058] Step 202, using a ball milling method to uniformly mix the precursor, or stir the precursor in a volatile organic solvent and then completely volatilize the organic solvent to obtain a precursor powder;

[0059] In step 203, the precursor powder is placed in a muffle furnace, and heat-treated in an air atmosphere at 800° C. to 1000° C. for 10 ...

Embodiment 3

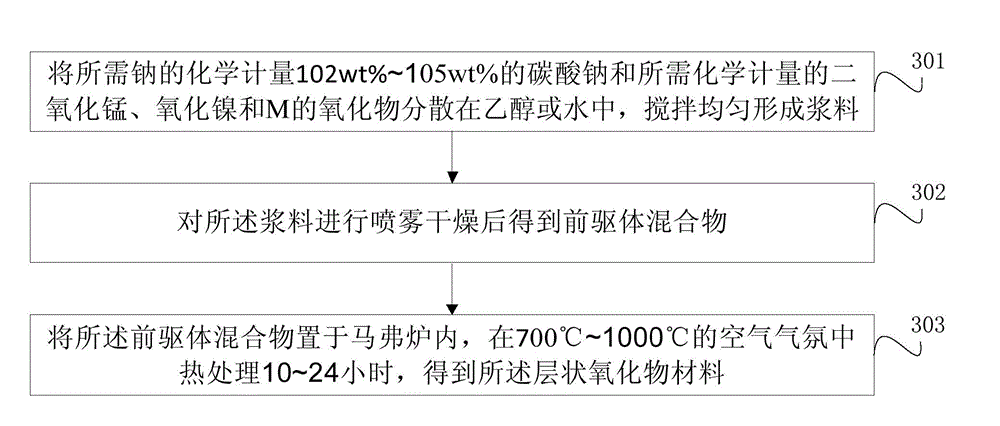

[0062] This example provides a method for preparing a sodium-rich P2 phase layered oxide material, specifically a spray drying method, such as image 3 shown, including:

[0063] Step 301, disperse the required stoichiometric sodium carbonate of 102wt% to 105wt% sodium carbonate and the required stoichiometric manganese dioxide, nickel oxide and M oxide in ethanol or water, and stir evenly to form a slurry;

[0064]Specifically, the M is specifically Mg 2+ , Zn 2+ , Cu 2+ , Mn 2+ ,Co 2+ , Al 3+ , Mn 3+ , Fe 3+ ,Co 3+ , V 3+ , Cr 3+ , Ti 4+ , Zr 4+ , Si 4+ , Sn 4+ , Ru 4+ , Nb 4+ , Mo 4+ one or more of.

[0065] Step 302, spray drying the slurry to obtain a precursor mixture;

[0066] In step 303, the precursor mixture is placed in a muffle furnace, and heat-treated in an air atmosphere at 700° C. to 1000° C. for 10 to 24 hours to obtain the layered oxide material.

[0067] The preparation method of the layered oxide material provided in this embodiment can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com