Field effect tube gas sensor based on shellac encapsulation/regulation and preparation method thereof

A gas sensor and field effect transistor technology, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, instruments, etc., can solve the problems of increased cost and complicated preparation process, and achieve the effects of stable detection, simple preparation process and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

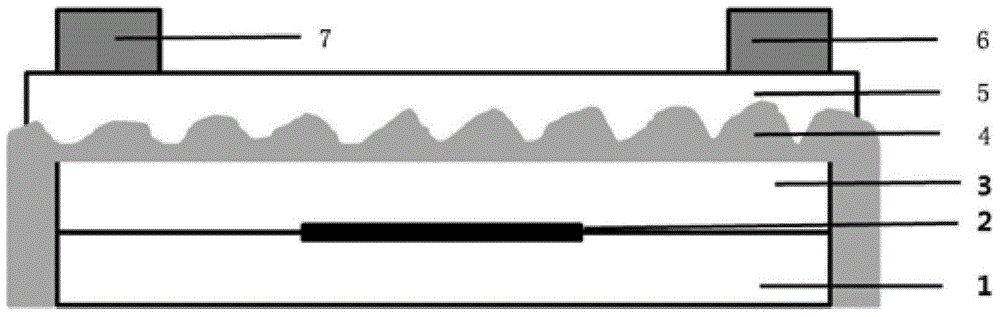

[0046] like figure 1The bottom-gate-top-contact structure is shown, and the material and thickness of each layer are as follows: the degradable substrate is plant fiber, the gate electrode is aluminum, and the thickness is 30 nm. The insulating layer is prepared by polyvinyl alcohol solution dissolved in water, and the thickness is The shellac layer is prepared by 10 wt% solution with a thickness of 50 nm, the semiconductor layer is zinc oxide with a thickness of 30 nm, the source electrode and the drain electrode are Au with a thickness of 30 nm, this structure can realize the Effective detection of nitrogen dioxide.

[0047] The preparation method is as follows:

[0048] ① Thoroughly clean the degradable substrate, and dry it with dry nitrogen after cleaning;

[0049] ② Sputtering gate electrodes on the surface of the degradable substrate;

[0050] ③ Spin coating an insulating layer on the gate electrode and process the insulating layer;

[0051] 4. adopt spin-coating me...

Embodiment 2

[0058] like figure 1 The bottom-gate top-contact structure is shown, and the materials and thicknesses of each layer are as follows: the degradable substrate is fibrin gel, the gate electrode is aluminum, and the thickness is 30 nm. The insulating layer is made of polyvinylpyrrolidone dissolved in water. The thickness is 500 nm, the shellac layer is prepared by 10 wt% solution, the thickness is 50 nm, the semiconductor layer is tin oxide, the thickness is 100 nm, the source electrode and the drain electrode are Au, the thickness is 80 nm, the structure can realize Effective detection of hydrogen sulfide.

[0059] Preparation method is like embodiment 1.

Embodiment 3

[0061] like figure 1 The bottom-gate top-contact structure is shown, and the materials and thicknesses of each layer are as follows: the degradable substrate is gelatin, the gate electrode is aluminum, and the thickness is 80 nm. The insulating layer is prepared by polyvinylpyrrolidone dissolved in glycerol. The thickness is 500 nm, the shellac layer is prepared by 20 wt% solution, the thickness is 50 nm, the semiconductor layer is zinc oxide, the thickness is 50 nm, the source electrode and the drain electrode are Au, the thickness is 50 nm, the structure can realize Effective detection of nitrogen dioxide.

[0062] Preparation method is like embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com