Camellia oil with strong sauce flavor and preparation method thereof

A camellia oil and flavor technology, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc., can solve the problem of the inability to form and bring out the aroma compounds of camellia oil, the disappearance of the unique flavor of camellia oil, and the loss of the flavor of camellia oil And other problems, to achieve the specific and reasonable effect of the programmed cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

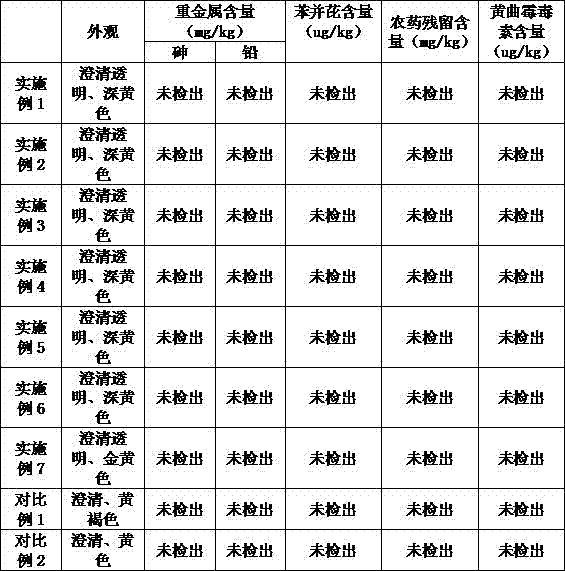

Embodiment 1

[0046] A kind of camellia oil with rich sauce flavor was prepared by the following method:

[0047] A. Preparation of tea seed kernels: take fresh tea seeds of that year, spread them out to dry naturally, so that the water content of the tea seeds is controlled at 10-20% by mass; remove the husks of the tea seeds to obtain the tea seed kernels;

[0048] B. Making fermented husks:

[0049] Lay the fruit husks obtained in step A indoors, pack them in mesh bags at a height of 1.5 meters, ventilate, and stack them for 5 days; the tea berries produce a special flavor, spread them out to dry naturally, and then remove surface dust or possible contamination Harmful substances, fermented husks were obtained, and crushed into pieces within 2 cm by a crusher;

[0050] C. Ripening: Add 1200 kg of fermented husks obtained in step B to 10,000 kg of camellia seed kernels obtained in step A, the fermented husks account for 10.7% by mass of the total amount, mix evenly to obtain a mixture of...

Embodiment 2

[0056] Using the method basically the same as that of Example 1, the camellia oil with strong sauce-flavored flavor of Example 2 was prepared. The main differences include: in the step B of making fermented husks, the high-quality fresh camellia oleifera fruit is directly peeled to obtain fresh husks; Put it in a special place where the rain can't get out, the thickness is less than 20 cm, ventilated, and the stacking time is 7 days; the husk produces a special flavor, removes the surface dust or harmful substances that may be polluted, and makes the fermented husk, and passes through the crusher Broken into pieces within 2 cm;

[0057] In step C, 10,000 kg of camellia seed kernels are added with 4,000 kg of fermented husks, the husk content is 28.6% by mass, the roasting temperature is 130°C, and the pressing chamber temperature in step D is 110°C; in step E, the shell oil mixture contains 20% by mass of camellia oil, and when pressed The temperature of the pressing chamber i...

Embodiment 3

[0061] Using the method basically the same as that of Example 1, the camellia oil with strong sauce-flavored flavor of Example 3 was prepared. The main differences include: in step C, 10,000 kg of camellia seed kernels were added with 3,000 kg of fermented husks, the husk content was 23.1% by mass, and roasted The temperature is 140°C, the temperature of the pressing chamber in step D is 120°C, the mixture of shell oil in step E contains 25% by mass of camellia oil, the temperature of the pressing chamber during pressing is 120°C, and the mixture of shell oil in step E contains 8.5% by mass of water; other conditions are the same .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com