Flaky titanium dioxide/bismuth oxybromide composite photocatalyst and preparation method thereof

A technology of titanium dioxide and bismuth oxybromide, which is applied in the field of photocatalysis, can solve the problem of high hole-electron recombination rate, and achieve the effects of simple preparation process, excellent photocatalytic performance, and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1.1 Add 0.2mL tetrabutyl titanate to 25mL isopropanol, stir well to mix evenly, then slowly add 0.8mL inducer hydrofluoric acid, stir to obtain a uniform white emulsion, that is, the precursor solution ;

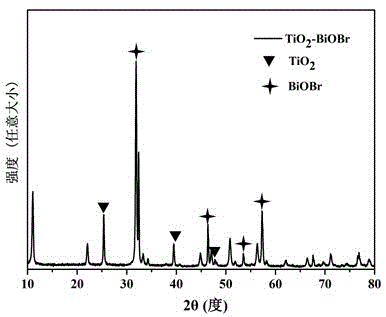

[0035] 1.2 Transfer the precursor solution to the reactor, react at 180°C for 20 h, centrifuge and wash after the reaction to obtain titanium dioxide nanosheets, figure 1 is the X-ray diffraction pattern of titanium dioxide nanosheets, figure 2 It is a scanning electron micrograph of the obtained titanium dioxide nanosheets. from figure 1 It can be seen that the obtained product is anatase phase titanium dioxide; from figure 2 It can be seen that the average size of the titanium dioxide nanosheets is 150nm × 100nm, and the shape is uniform;

[0036] 1.3 Add 0.02g of titanium dioxide nanosheets, 0.05g of KBr, and 0.004mmol of mercaptoacetic acid into deionized water, and disperse ultrasonically for 30 minutes to obtain a uniform and transparent solution;

[0037...

Embodiment 2

[0041] 2.1 The preparation method of titanium dioxide nanosheets is the same as in Example 1;

[0042] 2.2 Add 0.02g of titanium dioxide nanosheets, 0.0252g of KBr, and 0.002mmol of mercaptoacetic acid into deionized water, and disperse ultrasonically for 30 minutes to obtain a uniform and transparent solution;

[0043]2.3 Dissolve 0.0304g of bismuth nitrate in 20ml of ethylene glycol, stir, add the dissolved bismuth nitrate solution into the uniform transparent solution of titanium dioxide nanosheets, and fully stir at room temperature to obtain a uniform milky white emulsion;

[0044] 2.4 The milky white emulsion was left to stand at room temperature for 3 hours, and then centrifuged and washed to obtain a flaky titanium dioxide / bismuth oxybromide composite photocatalyst.

[0045] 2.5 The average thickness of the composite photocatalyst bismuth oxybromide deposited layer is 10 nm.

Embodiment 3

[0047] 3.1 The preparation method of titanium dioxide nanosheets is the same as in Example 1;

[0048] 3.2 Add 0.02g of titanium dioxide nanosheets, 0.0119g of KBr, and 0.001mmol of thioglycolic acid into deionized water, and ultrasonically disperse for 30 minutes to obtain a uniform and transparent solution;

[0049] 3.3 Dissolve 0.0202g of bismuth nitrate in 20ml of ethylene glycol, stir, add the dissolved bismuth nitrate solution into the uniform transparent solution of titanium dioxide nanosheets, and fully stir at room temperature to obtain a uniform milky white emulsion;

[0050] 3.4 The milky white emulsion was left to stand at room temperature for 3 hours, and then centrifuged and washed to obtain a flaky titanium dioxide / bismuth oxybromide composite photocatalyst.

[0051] 3.5 The average thickness of the composite photocatalyst bismuth oxybromide deposited layer is 8 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com