Method for simultaneous desulfurization denitrification and mercury removal based on hydroxyl and sulphate radical oxidation

A technology for desulfurization, denitrification, mercury removal and sulfate radical removal. It is applied in chemical instruments and methods, separation methods, and dispersed particle separation, and can solve problems such as increased initial investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

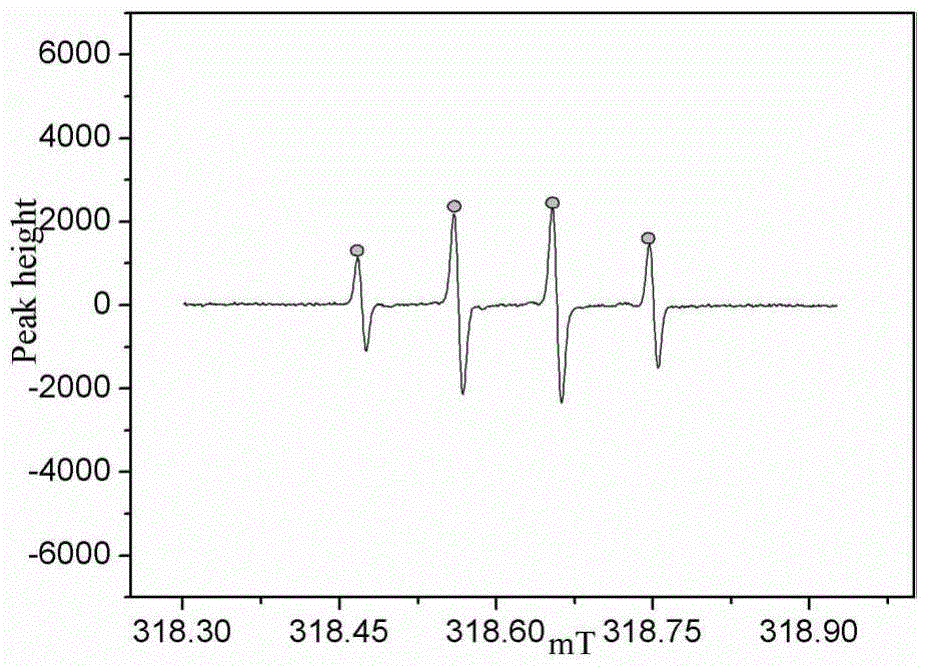

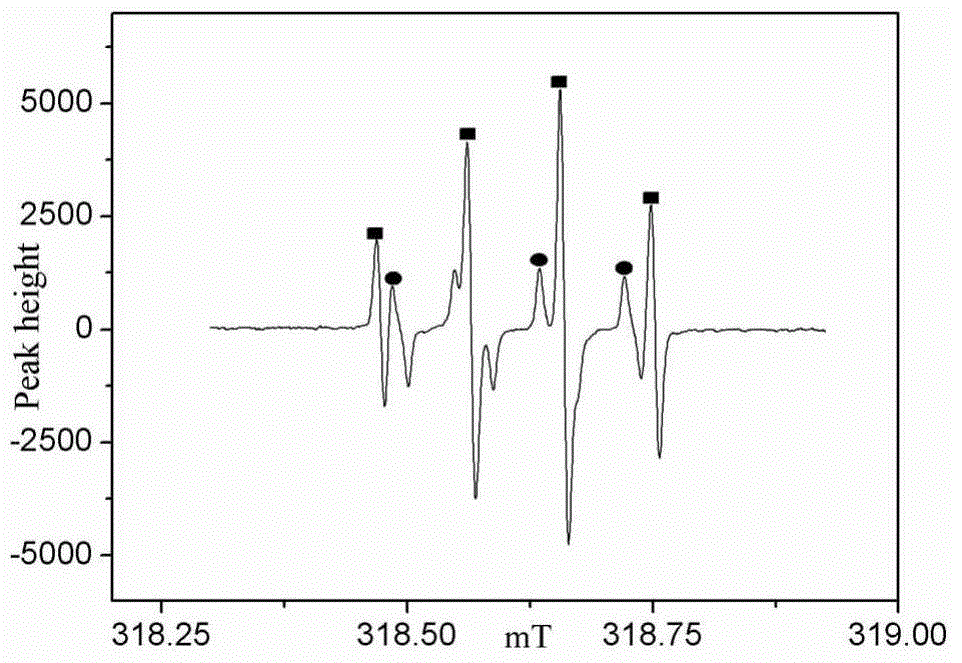

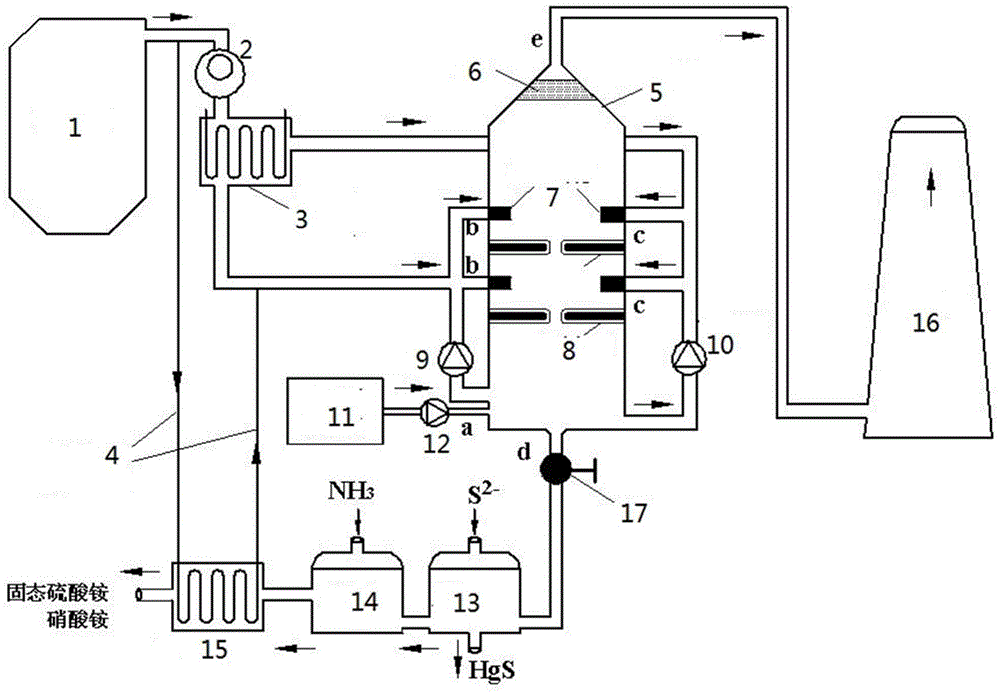

Method used

Image

Examples

Embodiment 1

[0066] Example 1. SO in flue gas 2 NO x With Hg 0 The concentrations are 2000ppm, 400ppm and 50μg / m respectively 3 , The flue gas temperature is 50℃, the ultraviolet wavelength is 254nm, and the UV radiation intensity is 30μW / cm 2 , The molar concentration of ammonium persulfate is 0.6mol / L, the solution pH is 3.5, and the liquid-gas ratio is 2L / m 3 . The result of the small test: SO in the flue gas 2 NO x With Hg 0 The simultaneous removal efficiency can reach 97.2%, 72.2% and 83.3% respectively.

Embodiment 2

[0067] Example 2. SO in flue gas 2 NO x With Hg 0 The concentrations are 2000ppm, 400ppm and 50μg / m respectively 3 , The flue gas temperature is 50℃, the ultraviolet wavelength is 254nm, and the UV radiation intensity is 30μW / cm 2 , The molar concentration of hydrogen peroxide is 0.6mol / L, the solution pH is 3.5, and the liquid-gas ratio is 2L / m 3 . The result of the small test: SO in the flue gas 2 NO x With Hg 0 The simultaneous removal efficiency can reach 99.3%, 75.4% and 86.2%.

Embodiment 3

[0068] Example 3. SO in flue gas 2 NO x With Hg 0 The concentrations are 2000ppm, 400ppm and 50μg / m respectively 3 , The flue gas temperature is 50℃, the ultraviolet wavelength is 254nm, and the UV radiation intensity is 30μW / cm 2 , The molar concentration of ammonium persulfate is 1.2mol / L, the pH of the solution is 3.5, and the liquid-gas ratio is 2L / m 3 . The result of the small test: SO in the flue gas 2 NO x With Hg 0 The simultaneous removal efficiency can reach 100%, 82.5% and 89.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com