High-performance frictional generator and preparation method thereof

A triboelectric generator and high-performance technology, applied in the direction of triboelectric generators, etc., can solve the problems of low energy conversion efficiency, high output voltage, low output current, etc., and achieve the effects of high energy conversion efficiency, high flexibility and strong output capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

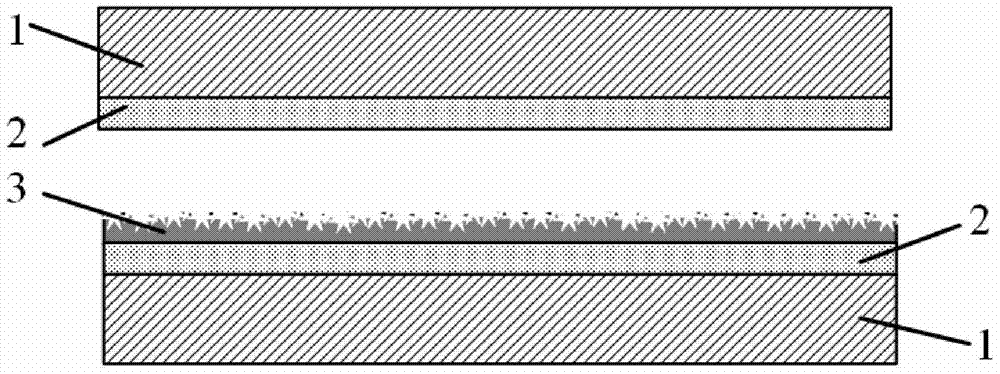

[0028] see figure 1 As shown, this embodiment is a high-performance triboelectric generator of the present invention with a contact-separated structure, including sequentially stacked polymer films 1 and conductive electrodes 2, and sequentially stacked polymer insulating layers 3, conductive electrodes 2 and polymer Thin Film 1.

[0029] Preferably, the polymer film 1 and the polymer insulating layer 3 are flexible insulating materials, and the flexible insulating materials include polyethylene (polyethylene, PE), polyvinyl chloride polymer (PVC) polydimethylsiloxane Alkane (polydimethylsiloxane, PDMS), polyimide (polymide, PI), parylene (parylene), polytetrafluoroethylene (polytetrafluoroethylene, PTFE) film, etc.

[0030] Preferably, the conductive electrode 2 is a metal with a resistivity of less than 1000Ω·m such as aluminum, copper, silver, gold or a semiconductor material including indium tin oxide (ITO) and a new type of conductive electrode such as graphene, carbon n...

Embodiment 2

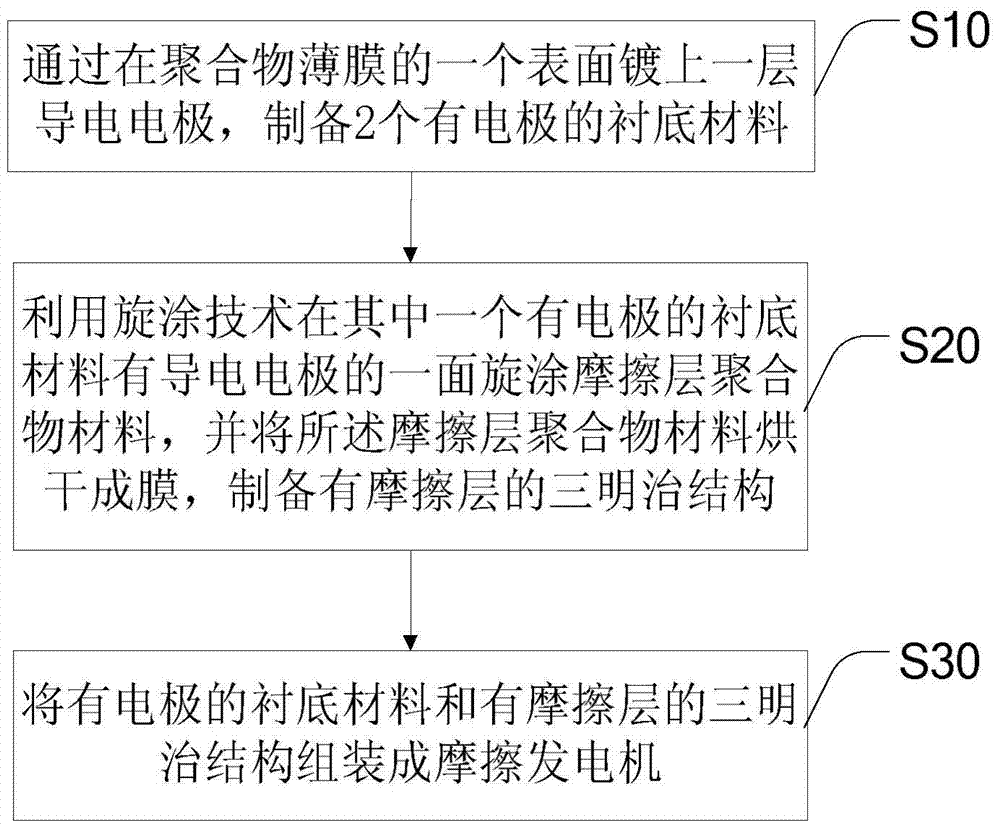

[0034] figure 2 It is a schematic flowchart of a preparation method of a high-performance friction generator in this embodiment.

[0035] refer to figure 2 Shown, the preparation method of a kind of high-performance friction generator of the present invention, concrete processing steps are as follows:

[0036] Step S10: Prepare two substrate materials with electrodes by plating a layer of conductive electrodes on one surface of the polymer film.

[0037] Preferably, in the step S10), the polymer film is a flexible insulating material including polyethylene terephthalate (polyethylene terephthalate, PET), organic glass and the like.

[0038] Preferably, in this step S10), the conductive electrodes are metals with strong electrical conductivity such as aluminum, copper, silver, gold or semiconductor materials including indium tin oxide (ITO) and new conductive electrodes such as graphene and carbon nanotubes. and styrene sulfonic acid (PEDOT-PSS).

[0039] Step S20: using ...

Embodiment 3

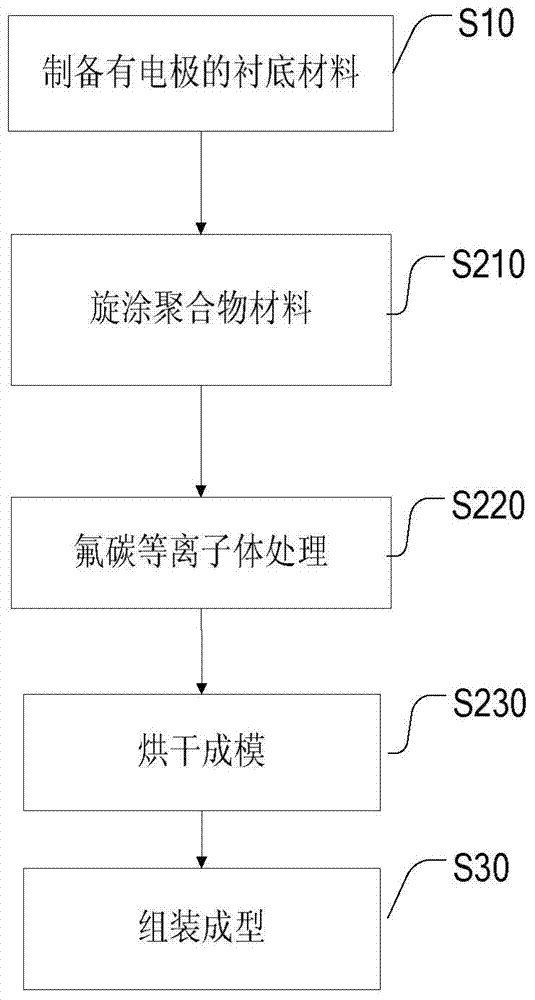

[0043] image 3 It is a schematic flowchart of a method for preparing a high-performance friction generator according to Example 3 of the present invention.

[0044] As a preferred version of the above-mentioned embodiment 2, see image 3 As shown, the preparation method of a high-performance friction generator in this embodiment comprises the following steps:

[0045] Step S10: preparing a substrate material with electrodes.

[0046] In this embodiment, PET is used for the polymer film, and ITO is used for the conductive electrode.

[0047] Specifically, the step is: plating a layer of conductive electrode ITO on one surface of the polymer film PET as a substrate material.

[0048] Step S210: spin coating the polymer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com