Rapid salt-bath nitridation method by applying magnetic field

A technology of salt bath nitridation and magnetic field, applied in the field of fast salt bath nitridation by applying magnetic field, can solve the problems of energy consumption and reduce production efficiency, and achieve the effects of saving energy, reducing processing time and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] 1) Grind the surface of the 42CrMo gear with 400#~2000# SiC sandpaper in sequence, and then use absolute ethanol to clean the gear with ultrasonic waves for 10 minutes to remove surface oil and other impurities, and dry it for later use;

[0025] 2) Put the 42CrMo gear into the resistance furnace for pre-oxidation, the pre-oxidation temperature is 430°C, and the time is 25min;

[0026] 3) heating up the nitriding furnace to 470°C for heat preservation, and after the nitriding base salt containing 34% cyanate in the crucible in the nitriding furnace is fully melted, the temperature is raised to 565°C;

[0027] 4) Take out the pre-oxidized 42CrMo gear and put it into a nitriding furnace, seal and heat, apply a magnetic field of 0.5T, the nitriding temperature is 565°C, and the holding time is 50min;

[0028] 5) Wash the nitrided 42CrMo gear with water and dry it.

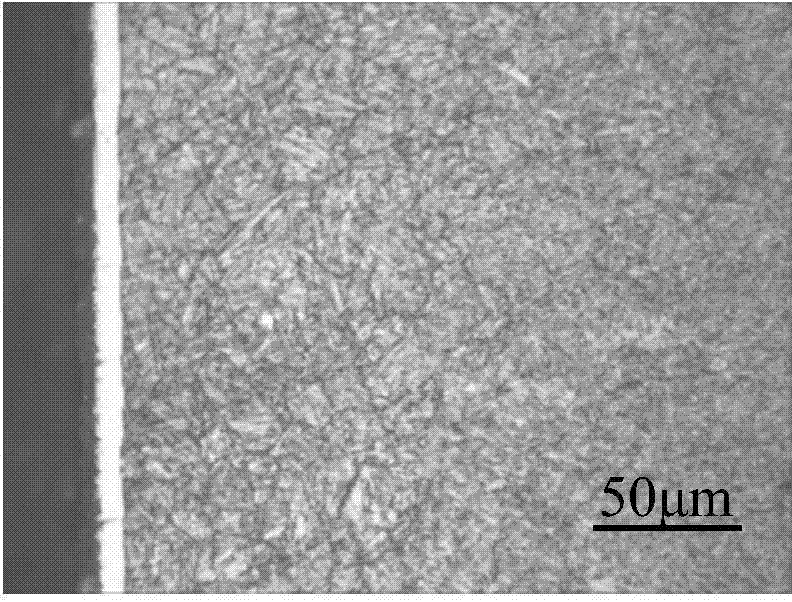

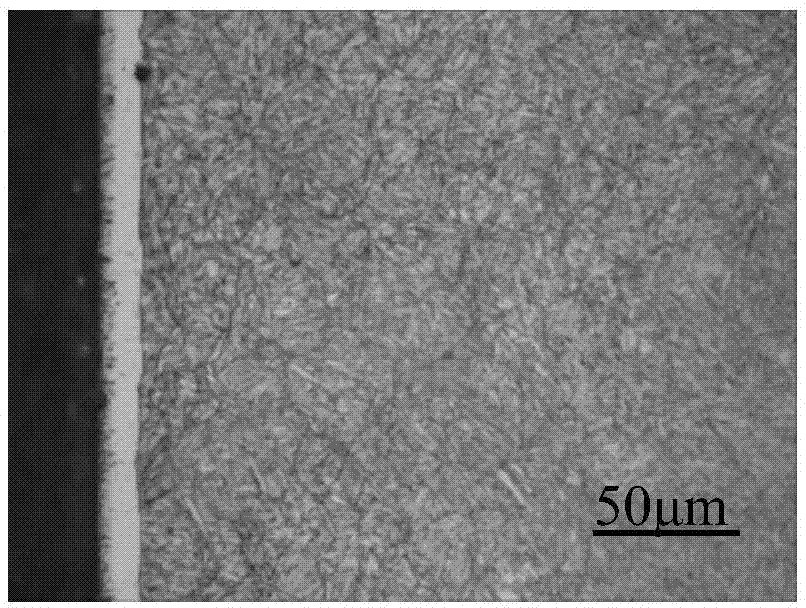

[0029] 1. Conduct metallographic test on the surface of 42CrMo gear

[0030] figure 1 It is the surface m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com