A kind of preparation method of micronano zeaxanthin

A micro-nano technology of corn yellow pigment, applied in the field of preparation of micro-nano corn yellow pigment, can solve the problems of poor water solubility and large loss of pigment, and achieve the effect of high encapsulation rate, high added value and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

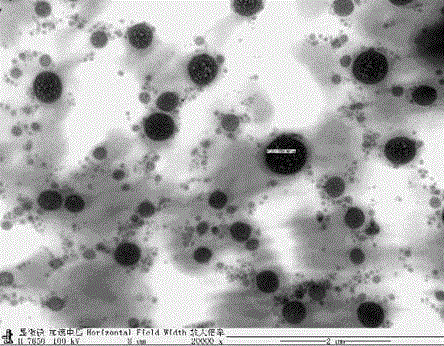

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: a kind of preparation method of micronano zeaxanthin is realized through the following steps:

[0028] ( 1 ) Raw material screening and pretreatment

[0029] Take a certain amount of corn yellow powder, crushed to 60~80 mesh, add water to adjust the moisture to 15~20% , balanced moisture 20~24h ;

[0030] ( 2 ) extrusion puffing treatment

[0031] Put the pretreated raw materials into the twin-screw extrusion extruder, at the extrusion barrel temperature 130~170 °C, screw speed 150~250r / min Under certain conditions, slowly and evenly add corn yellow powder to carry out extrusion puffing. Then after crushing by the pulverizer, the 60 Mesh sieve, obtain the corn yellow powder after pretreatment;

[0032] ( 3 ) corn yellow pigment extraction

[0033] Ultrasonic method is adopted, that is, the above-mentioned pulverized raw materials are weighed, and 10~20 times the volume of ethanol solution mixed at ultr...

specific Embodiment approach 2

[0036] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one lies in the steps ( 1 ) by adding water to adjust the moisture to 18% . Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one lies in the steps ( 2 ) Extrusion cylinder temperature 140~160 °C, screw speed 160~200r / min.

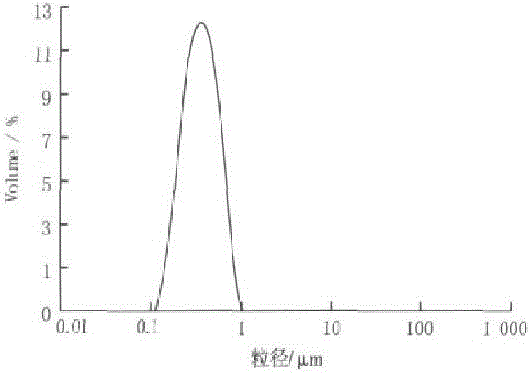

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com