Separation system

A technology of mineral separation and wind-magnetic separation, applied in the field of mineral separation system, can solve the problems of increased energy consumption and belt consumption, pollution, ash emitting air, etc., to save equipment costs and water resources, improve pellet efficiency, and optimize the overall The effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

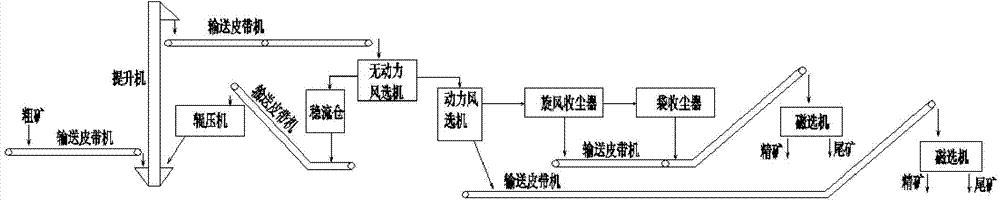

[0049] Embodiment 1: A mineral separation system, including a roller press, a steady flow bin, a wind classification system, a dynamic screening system, and a dry wind magnetic separation system, and the mineral separation system is arranged longitudinally.

[0050] In the process of magnetic separation, the crushed coarse ore first enters the wind classification system, which classifies the coarse ore, selects fine ore that meets the particle size requirements and sends it to the dynamic screening system. Coarse ore that meets the particle size requirements is fed into the steady flow bin, and then sent to the roller press through the collection and control of the steady flow bin. The roller press crushes the coarse ore to crush The coarse ore after roller crushing is sent to the wind classification system again for classification; the dynamic screening system screens the fine ore, and selects ultra-fine ore that meets the particle size requirements and feeds the dry type The wi...

Embodiment 2

[0052] Example 2: Such as Figure 5 As shown, a mineral separation system includes a roller press, a steady flow bin, a wind classification system, a dynamic screening system, and a dry wind magnetic separation system. The mineral separation system is longitudinally arranged; a roller press, a steady flow bin , The wind classification system, the dynamic screening system and the dry wind magnetic separation system are arranged in four layers in the longitudinal direction, from the bottom to the top layer from the first layer to the fourth layer. The roller press is arranged on the first layer, so The steady flow bin is arranged on the second floor, the wind classification system is arranged on the third floor, the dynamic screening system is arranged on the fourth floor, and the dry wind magnetic separation system is arranged on the first, second and third floors. .

[0053] In the process of magnetic separation, the crushed coarse ore first enters the wind grading system on the ...

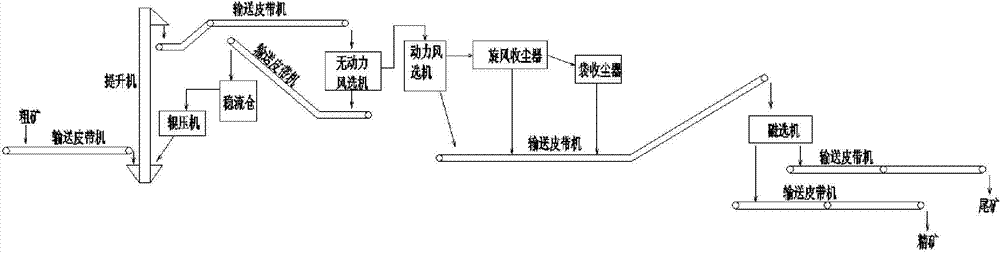

Embodiment 3

[0055] Example 3: Such as Image 6 As shown, a mineral separation system includes a roller press, a steady flow bin, a wind classification system, a dynamic screening system, and a dry wind magnetic separation system. The mineral separation system is longitudinally arranged; a roller press, a steady flow bin , The wind classification system, the dynamic screening system and the dry wind magnetic separation system are arranged in three layers in the longitudinal direction, the roller press is arranged on the bottom layer, the steady flow bin is arranged on the middle layer, the wind classification system and the power The screening system is arranged on the top layer, and the dry wind magnetic separation system is arranged on the middle layer and the bottom layer; the dry wind magnetic separation system includes a transition bin and a dry wind magnetic separation unit. The transition bin is located on the middle layer. The dry wind magnetic separation unit is set on the bottom la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com