Method for manufacturing hollow magnetic torquer

A manufacturing method and a technology for a magnetic torque device, which are applied in the aerospace field, can solve the problems of complicated processing and poor stability of the hollow-core magnetic torque device, and achieve the effects of improving fixing reliability, strong stability and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a method for manufacturing a hollow magnetic torque device, comprising the following steps:

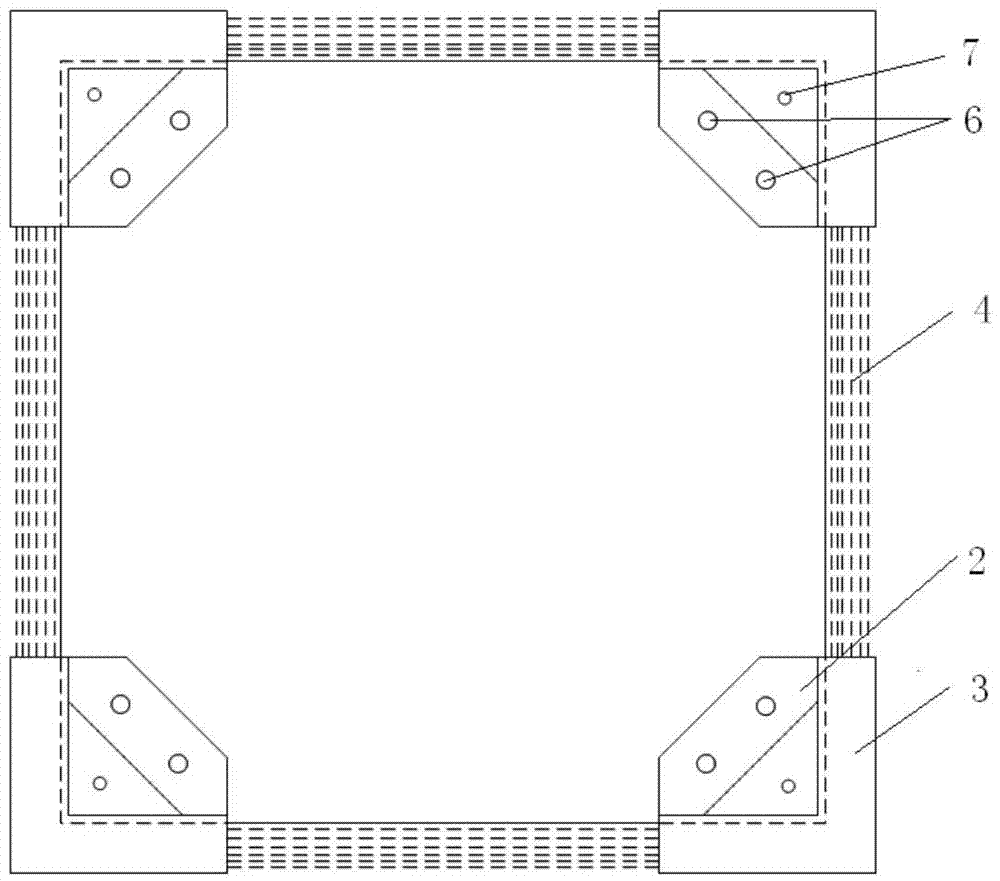

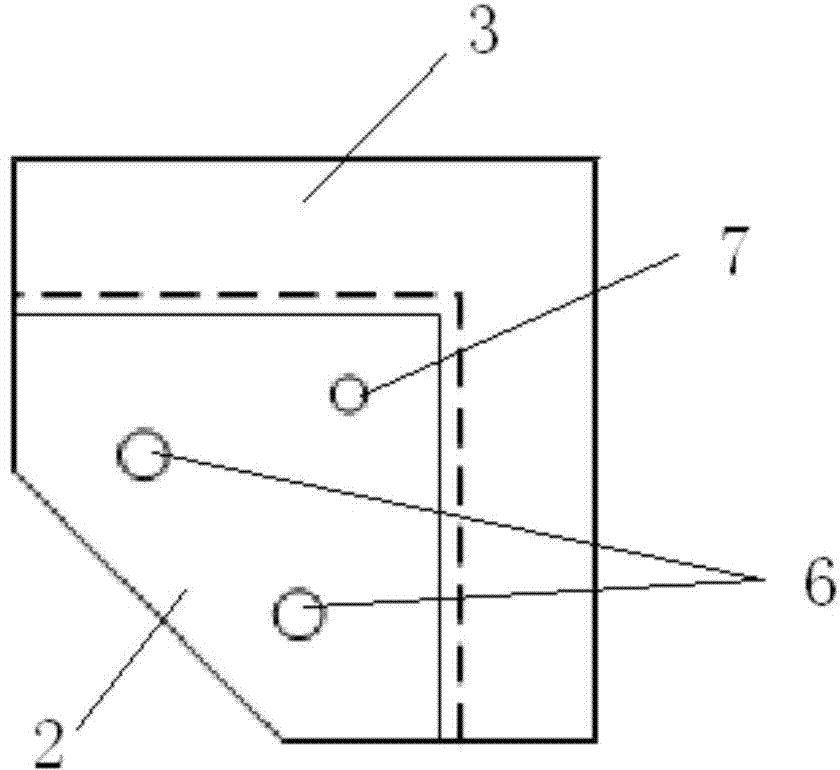

[0028] a. The four top corners of the square fixed plate 1 are respectively detachably installed with winding slots 3, such as figure 2 shown;

[0029] First, according to the design size of the air-core magnetic torque device, combined with the thickness requirements of the air-core magnetic torque device, design a mold that can not only provide the environment for coil winding, but also provide an interface for the fixing of the coil. The abrasive tool includes a winding groove 4 and a fixed plate 1. In the design and processing process, the dimensions of the winding groove 4 and the fixed plate 1 must be precisely matched. The material of the abrasive tool should be non-magnetic materials such as duralumin. So as n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com