Steel-plastic composite pipe cutting end surface plastic seal device and application thereof

A technology of steel-plastic composite pipe and cutting end, which is applied in the field of plastic sealing device for cutting end of steel-plastic composite pipe, can solve the problems of weak secondary injection molding and easy falling off, and achieve the effect of smooth port, temperature control and easy temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

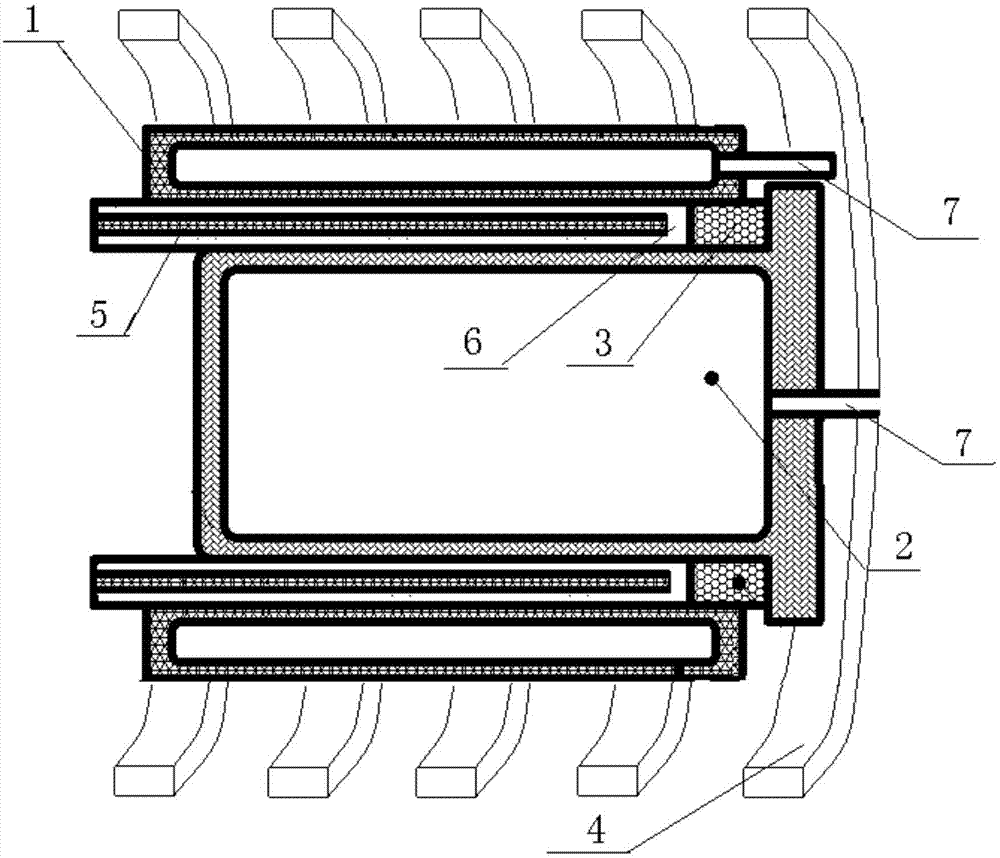

[0039] Such as figure 1 As shown, a steel-plastic composite pipe cutting end plastic sealing device in this embodiment includes an outer air bag 1, an inner air bag 2 and a plastic ring 3, and also includes a heater 4, and both the outer air bag 1 and the inner air bag 2 are provided with valves 7 , the outer airbag 1 is in the shape of a ring, with an inner diameter of 150 mm. When in use, the outer wall of the plastic layer 6 of the composite pipe is sleeved on the outer layer of the steel-plastic composite pipe; the section of the inner airbag 2 is "T" shaped, and the top "T" head is round Cover-shaped structure with a cylindrical air cavity with an outer diameter of 140mm at the lower part; the plastic ring 3 is a ring-cylindrical structure with an outer diameter of 150mm and an inner diameter of 140mm; the heater 4 is an electromagnetic heater, and its coil surrounds the outer wall of the outer airbag 1 .

[0040] A steel-plastic composite pipe cutting end face plastic s...

Embodiment 2

[0048] A steel-plastic composite pipe cutting end face plastic sealing device of this embodiment has the same basic structure as that of embodiment 1, the difference is that: the outer air bag 1 and the inner air bag 2 are rubber air bags resistant to high temperature aging; the plastic ring 3 is able to withstand a certain high temperature Non-deformable tetrafluoroplastic ring; the heater 4 is a high-frequency heater, and spirally hovers on the outer wall of the outer airbag 1, and its heating head is in the shape of a conductive metal strip spirally surrounding it, which has a better heating effect and can increase the heating speed .

[0049] A kind of steel-plastic composite pipe cutting end face plastic sealing device of this embodiment is applied to the steel-plastic composite pipe after the fixed-length cutting of the double-layer structure whose outer layer is the plastic layer 6 of the composite pipe and whose inner layer is the steel core layer 5 of the composite pip...

Embodiment 3

[0052] The plastic-sealing device for cutting end faces of steel-plastic composite pipes in this embodiment has the same basic structure as that of embodiment 2, the difference being that two sets of the device simultaneously plastic-seal the cut end faces of both ends of steel-plastic composite pipes.

[0053] The plastic sealing device for cutting the end face of a steel-plastic composite pipe of this embodiment is applied to a steel-plastic composite pipe with a composite pipe plastic layer 6 inside and outside, a three-layer structure of a composite pipe steel core layer 5 in the middle, and a fixed-length cut. The basic steps are the same as those in Example 2, except that two sets of the device are plastic-sealed at the same time, and the compressed air pressure is controlled at 0.15Mpa in step B; the heating time in step C is 10 seconds; the cooling time in step D is 8 minutes.

[0054] In this embodiment, a cutting end face plastic sealing device of a steel-plastic comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com