Extraction combination of biologically active substances and ultrasonic microwave combined extraction method

A technology for biologically active substances and combinations, which is applied in the field of biologically active substances extraction, can solve the problem that small volumes of tailings cannot be processed, and achieve the effects of improving or reducing processing capacity, less space, and high degree of intensification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

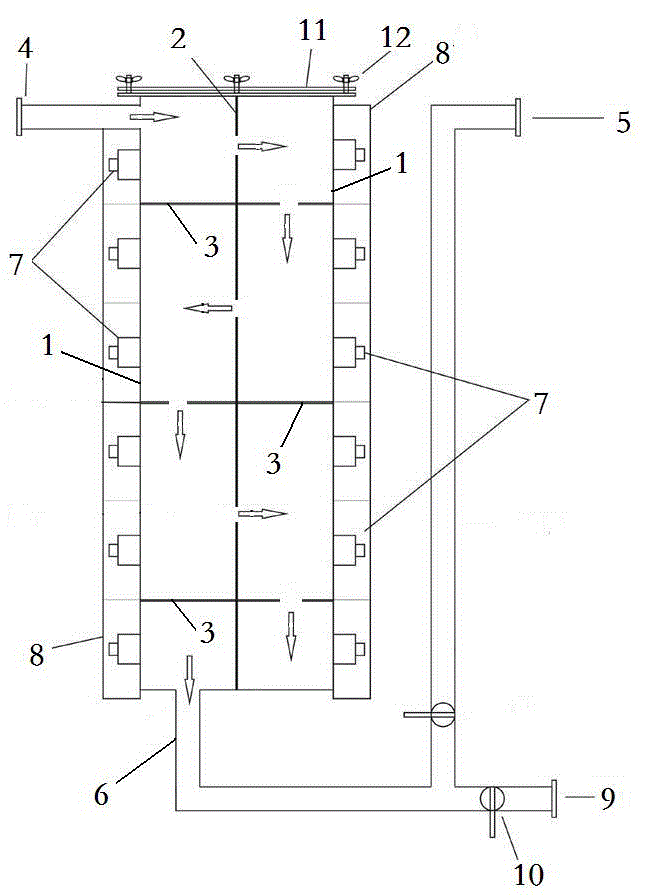

[0039] The structure of the ultrasonic extraction unit see figure 1 : The left and right ultrasonic vibrating plates 1 and the front and rear wall plates (not seen in the figure) form a vertical material chamber, which is divided into eight parts by a central longitudinal baffle 2 and three transverse baffles 3 therein. an extraction chamber. On the corresponding positions of the longitudinal partition 2 and the transverse partition 3, there are material flow holes that allow the material to flow through each extraction chamber from top to bottom (the arrows in the figure indicate the direction of material flow). The feed pipe 4 is connected with an extraction chamber at the top. The nozzle 5 rises to the discharge pipe 6 at the upper part of the material chamber, which is connected with an extraction chamber at the bottom. The ultrasonic vibrating plate 1 is provided with an ultrasonic head 7 at a corresponding position of each extraction chamber. figure 1 Middle 8 is an u...

Embodiment 2

[0047] Carry out the extraction of kidney bean bean powder active substance by the device of embodiment 1. Add water to the first material storage mixing tank, turn on the heating system to heat the interlayer and the liquid in the tank, then add soybean powder as required, and turn on the stirring device for mixing. After the material mixing is completed, the valve can be opened to allow the material liquid to enter the extraction assembly for circular extraction, and filter after the extraction is completed. The filtrate enters the storage tank of the second material storage mixing tank through the conduit. At this time, the extraction of one tank of material is completed, and the first material storage mixing tank is emptied, and materials can be added for the next extraction.

Embodiment 3

[0049] Carry out the extraction of kidney bean bean powder active substance by the device of embodiment 1. Kidney bean bean flour active substance extraction. Add water to the first material storage mixing tank, turn on the heating system to heat the interlayer and the liquid in the tank, then add soybean powder as required, and turn on the stirring device for mixing. After the mixing is completed, the valve can be opened to allow the material liquid to enter the extraction assembly for cyclic extraction, turn on the power supply of the ultrasonic extraction unit and the ultrasonic part in the ultrasonic-microwave extraction unit, and turn off the microwave power supply. At this time, simple ultrasonic treatment is used, but the two The ultrasound frequency is different in the extraction unit. Filtered after sonication at different frequencies and complete extraction. The filtrate enters the emptied secondary material storage mixing tank through the conduit. The first mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com