Optical proximity correction method

An optical proximity correction and photon technology, which is applied in optics, microlithography exposure equipment, and originals for photomechanical processing, can solve problems such as deviation and semiconductor device performance, and achieve the effect of reducing the change of overlapping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

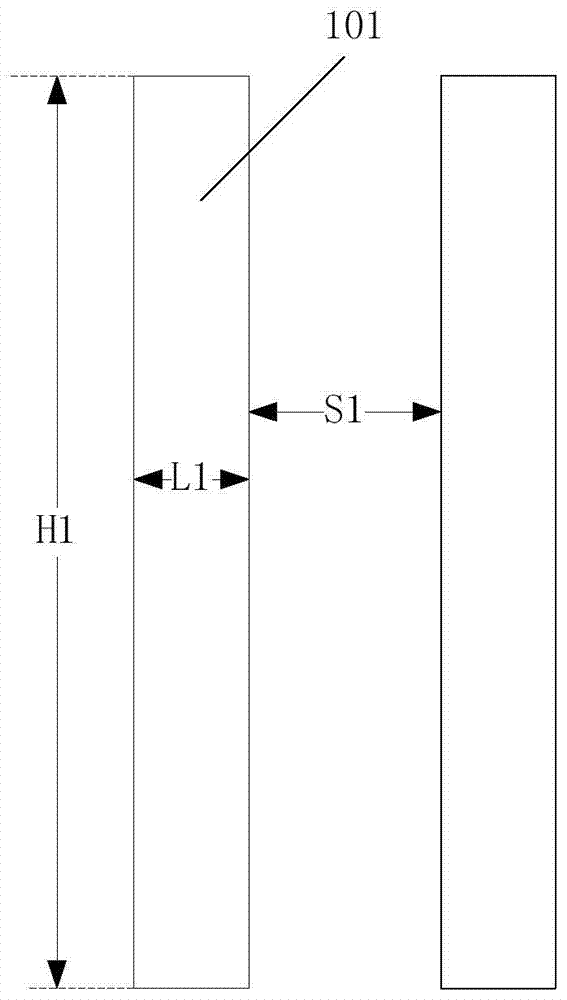

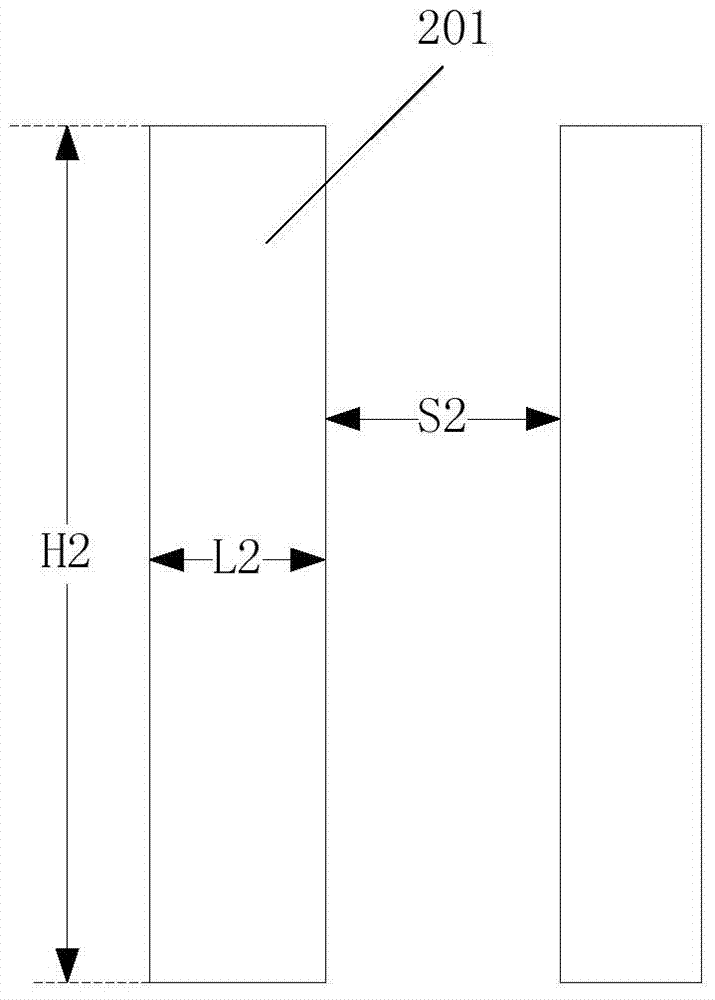

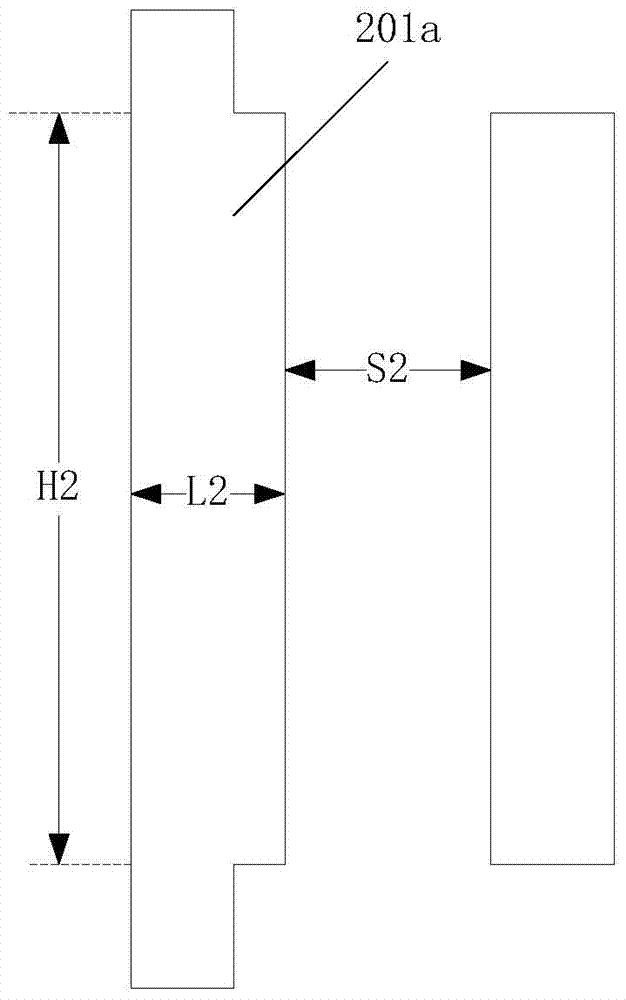

[0035] As described in the background technology, by changing the width of the exposure target pattern, the exposure target pattern is changed from an unexposed pattern to an exposed pattern, resulting in the size of the material layer to be etched corresponding to the exposure target pattern after being etched. There is a certain deviation from the design size, which may affect the performance of the semiconductor device in the chip.

[0036] Research has found that in the process of forming a polysilicon gate with a polysilicon layer as an etching material layer, reducing the width of the exposure target for etching the polysilicon layer will reduce the width of the finally formed polysilicon gate, thereby causing the polysilicon gate The channel width of the transistor where it is located is reduced, which affects the electrical parameters such as the saturation current of the transistor and affects the performance of the transistor; and the metal plug that should have been ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com