Efficient desulfurizing bacreria and use method thereof in removal of sulfur in iron ore

A desulfurization bacteria and high-efficiency technology, applied in the field of removing sulfur in iron ore, can solve the problems of increased production cost, excessive consumption of coke limestone, etc., and achieve the effect of low production cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

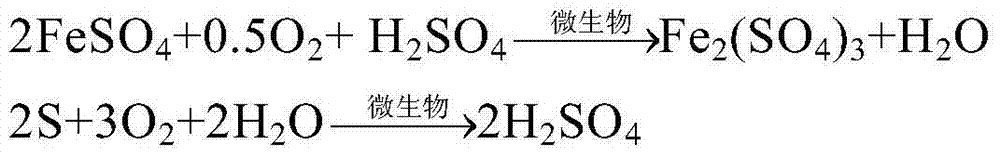

Method used

Image

Examples

Embodiment 1

[0029] The method of the present invention is applied to a certain iron ore in Inner Mongolia Autonomous Region, and the main element content of this iron ore is shown in Table 1

[0030] Table 1 Chemical multi-element analysis of an iron ore in Inner Mongolia Autonomous Region

[0031]

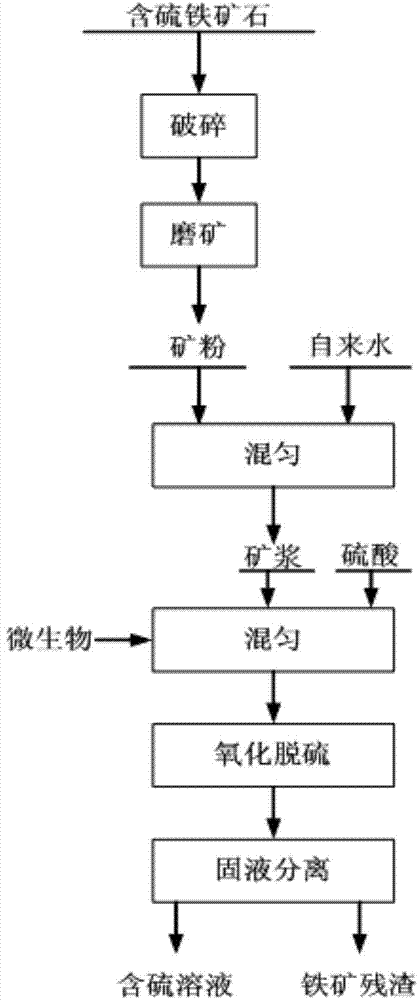

[0032] To desulfurize the above-mentioned ores, the technological process is as follows figure 1 As shown, it specifically includes the following steps:

[0033] 1. Crushing and fine grinding of ore

[0034] Crush the raw ore of sulfur-containing iron ore to less than 2mm, and then grind it to -0.074mm with a grinding machine, accounting for 65%;

[0035] 2. Preparation of pulp

[0036] Use tap water to make mineral powder into slurry, and the concentration of the slurry is 10%;

[0037] 3. Adjust pH and inoculate microorganisms

[0038] Use sulfuric acid with a concentration of 98% to adjust the pH of the pulp to 1.5, and inoculate high-efficiency desulfurization bacteria. The high-e...

Embodiment 2

[0043] The method of the present invention is applied to a certain iron ore in Hebei Province, and the main element content of this iron ore is shown in Table 2

[0044] Table 2 Chemical multi-element analysis of an iron ore in Hebei Province

[0045]

[0046] To desulfurize the above-mentioned ores, the technological process is as follows figure 1 As shown, it specifically includes the following steps:

[0047] 1. Crushing and fine grinding of ore

[0048] Crush the crude iron ore containing sulfur to less than 2mm, and then use a grinding machine to grind it to -0.074mm, accounting for 70%;

[0049] 2. Preparation of pulp

[0050] Use tap water to make mineral powder into slurry, and the concentration of the slurry is 15%;

[0051] 3. Adjust pH and inoculate microorganisms

[0052] Use 98% sulfuric acid to adjust the pH of the slurry to 1.8, and inoculate the high-efficiency desulfurization bacteria. The high-efficiency desulfurization bacteria are mixed bacteria of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com