Microwave-assisted preparation method for spherical transition metal and zirconium diphosphonate in one step

A zirconium bisphosphonate and transition metal salt technology, applied in the field of bisphosphonate preparation, can solve the problems of long process steps, environmental pollution, time-consuming, etc., and achieve low equipment requirements, high efficiency, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

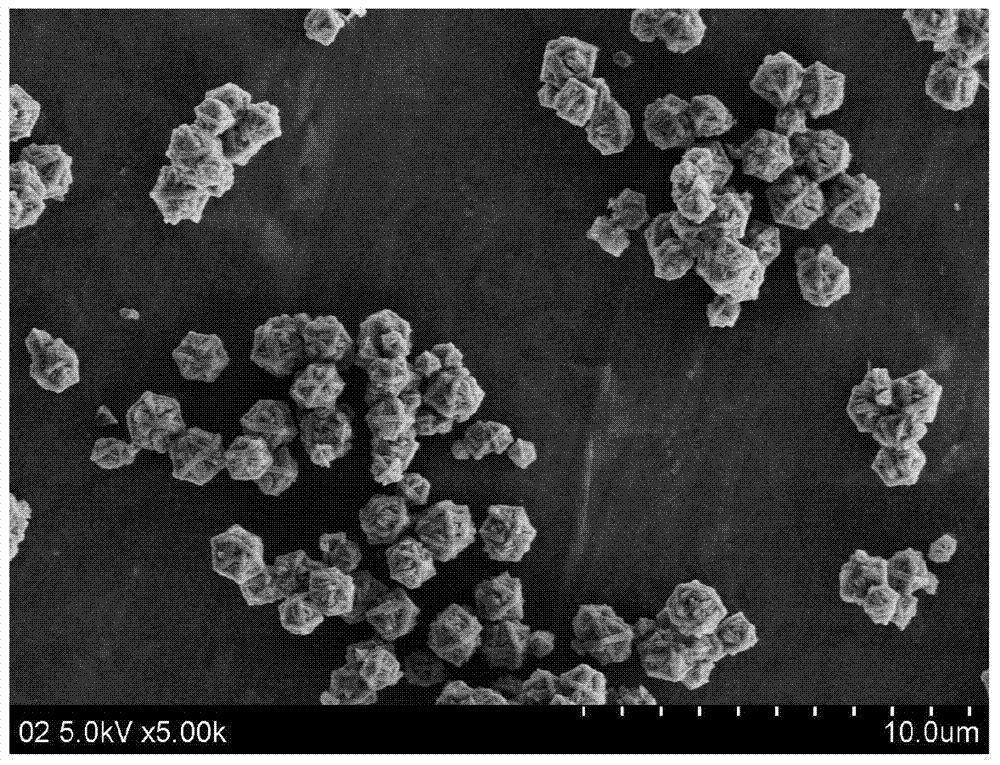

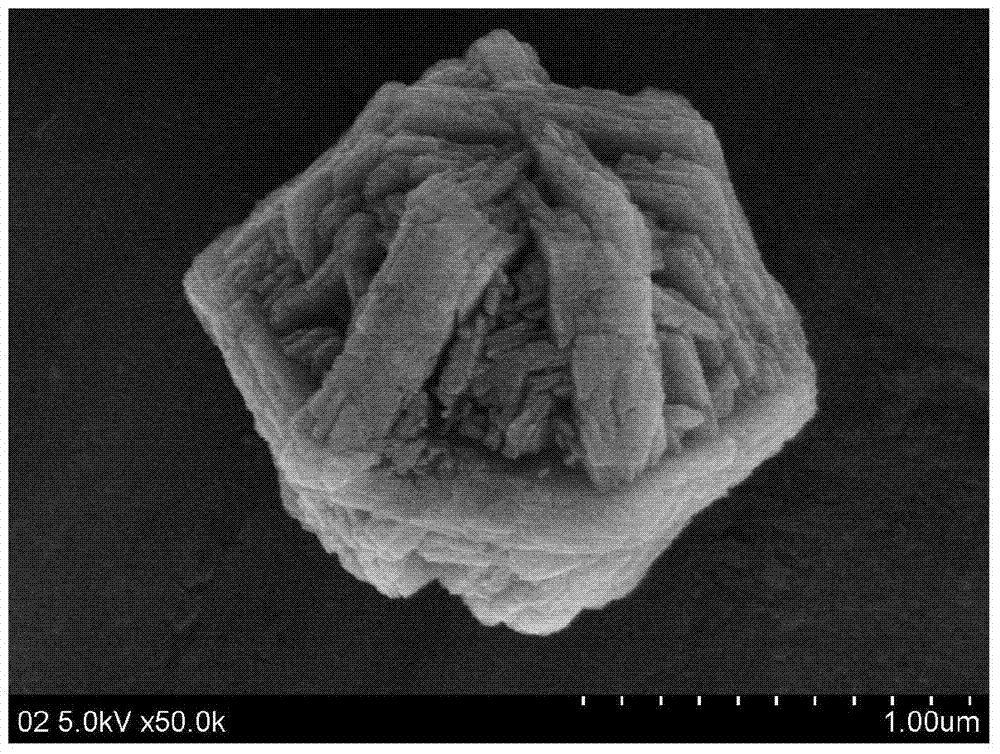

[0029] CoCl 2 , ZrOCl 2 , NaH 2 PO 4 and NH 4 F is formulated into aqueous solution respectively, mixes, wherein ZrOCl in the solution 2 The concentration of Zr / P is 0.005mol / L, the molar ratio of Zr / P is 1:20, the molar ratio of Zr / F is 1:6, and the molar ratio of Zr / Co is 1:1. The mixed solution was microwaved at 90°C for 30 min. After centrifugation, washing, and freeze-drying, spherical zirconium-cobalt bisphosphate ZrCo(PO 4 ) 2 4H 2 O, SEM characterization as figure 1 shown, where figure 2 yes figure 1 magnified view of .

Embodiment 2

[0031] Will Co(NO 3 ) 2 , ZrO(NO 3 ) 2 、Na 2 HPO 4 and NaF were prepared as aqueous solutions, mixed, wherein the solution ZrO(NO 3 ) 2 The concentration of Zr / P is 0.02mol / L, the molar ratio of Zr / P is 1:40, the molar ratio of Zr / F is 1:3, and the molar ratio of Zr / Co is 1:1. The mixed solution was microwaved at 85°C for 45min. After centrifugation, washing and drying at room temperature, spherical zirconium cobalt bisphosphate ZrCo(PO 4 ) 2 4H 2 O.

Embodiment 3

[0033] MnCl 2 , ZrOCl 2 , NH 4 h 2 PO 4 and NaF were formulated into aqueous solutions, mixed, wherein ZrOCl in the solution 2 The concentration of Zr / P is 0.005mol / L, the molar ratio of Zr / P is 1:40, the molar ratio of Zr / F is 1:6, and the molar ratio of Zr / Mn is 1:1. The mixed solution was microwaved at 90°C for 30 min. After centrifugation, washing, and freeze-drying, spherical zirconium manganese bisphosphate ZrMn(PO 4 ) 2 4H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com