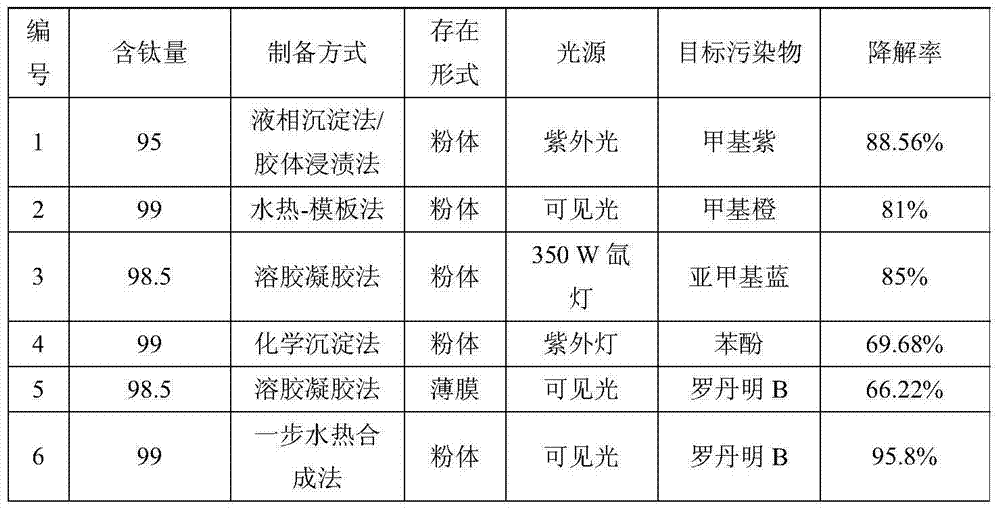

Preparation method for TiO2/WO3 composite powder

A composite powder, evenly mixed technology, used in chemical instruments and methods, chemical/physical processes, adsorbed water/sewage treatment, etc., can solve the problems of harsh reaction conditions, long reaction cycle, complex preparation process, etc. Low cost, short cycle time, high photodegradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, and stir at 40°C for 2 hours, then add acetyl Acetone, solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A mass.

[0029] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A at 40°C dropwise, and fully react after dropping for 2 hours to obtain solution B. Wherein, the quality of concentrated nitric acid is 0.2% of solution B quality.

[0030] 3) At room temperature, the K 2 WO 3 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0031] 4) According to the molar ratio of Ti and W elements n Ti :n W =x: (100-x), wherein x=...

Embodiment 2

[0039] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, stir at 40°C for 2 hours, and then add acetylacetone , solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A mass.

[0040] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A at 40°C dropwise, and fully react after dropping for 2 hours to obtain solution B. Wherein, the quality of concentrated nitric acid is 0.3% of solution B quality.

[0041] 3) At room temperature, the K 2 WO 4 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0042] 4) According to the element molar ratio n Ti :n W =x: (100-x), where x=70, solution B ...

Embodiment 3

[0044] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, stir at 40°C for 2 hours, and then add acetylacetone , solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A mass.

[0045] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A dropwise at 40° C., stir for 2 hours and fully react to obtain solution B. Wherein, the quality of concentrated nitric acid is 0.3% of solution B quality.

[0046] 3) At room temperature, the K 2 WO 4 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0047] 4) According to the molar ratio of Ti and W elements n Ti :n W =x: (100-x), wherein x=50, solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com