Large-diameter diffraction grating exposure device and manufacture method of large-diameter diffraction grating

A diffraction grating and exposure device technology, applied in the field of diffraction gratings, can solve the problems of difficulty in increasing power, prolonged exposure time, sensitivity to environmental changes, etc., and achieves the effects of improved imaging quality, easy large-diameter parabolic mirrors, and simple system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

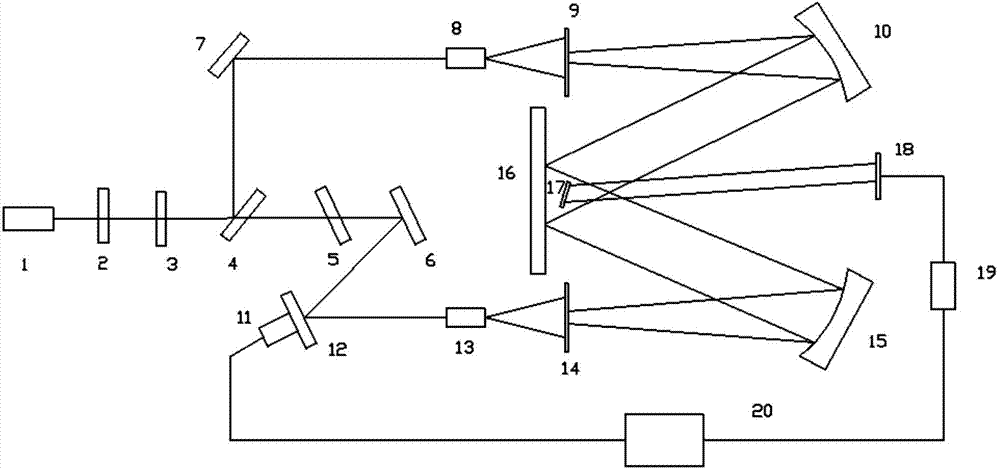

[0037] see figure 1, The exposure device of the large-aperture holographic grating of the present invention consists of a laser 1, an electronic shutter 2, a first half-wave plate 3, a polarizing beam splitter 4, a second half-wave plate 5, a first mirror 6, a second mirror 7, the first A spatial filter 8, a first rectangular aperture 9, a first large off-axis parabolic reflector 10, a piezoelectric ceramic 11, a third reflector 12, a second spatial filter 13, a second rectangular aperture 14, a second It consists of a large off-axis parabolic reflector 15, a substrate 16, a small reference grating 17, a receiving screen 18, a CCD 19 and a computer 20. The positional relationship of the above components is as follows:

[0038] The vertically polarized laser light emitted by the laser 1 passes through the electronic shutter 2 and the first half-wave plate 3 and is divided into two left and right beams by the polarizing beam splitter 4, and the left beam passes through the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grating constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com